Haulage roadway support advancing mechanism

A traveling mechanism and roadway support technology, applied in tunnels, mine roof supports, mining equipment, etc., can solve the problems of large outline size, complicated equipment operation, roadway damage, etc., and achieve the effect of reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

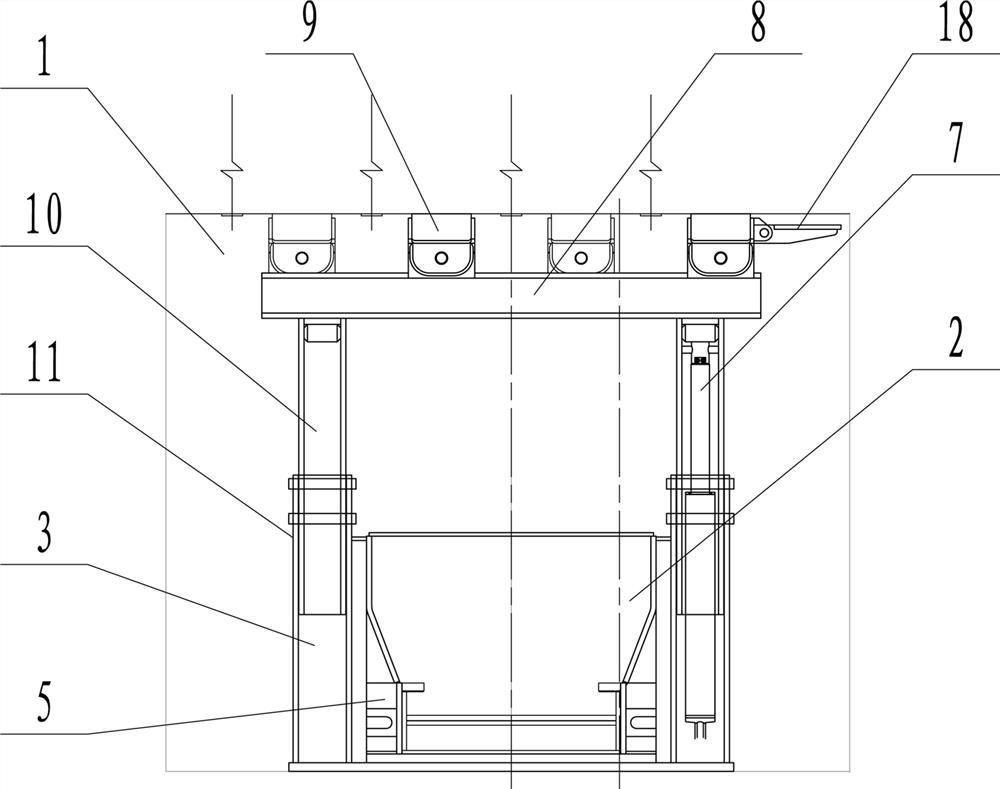

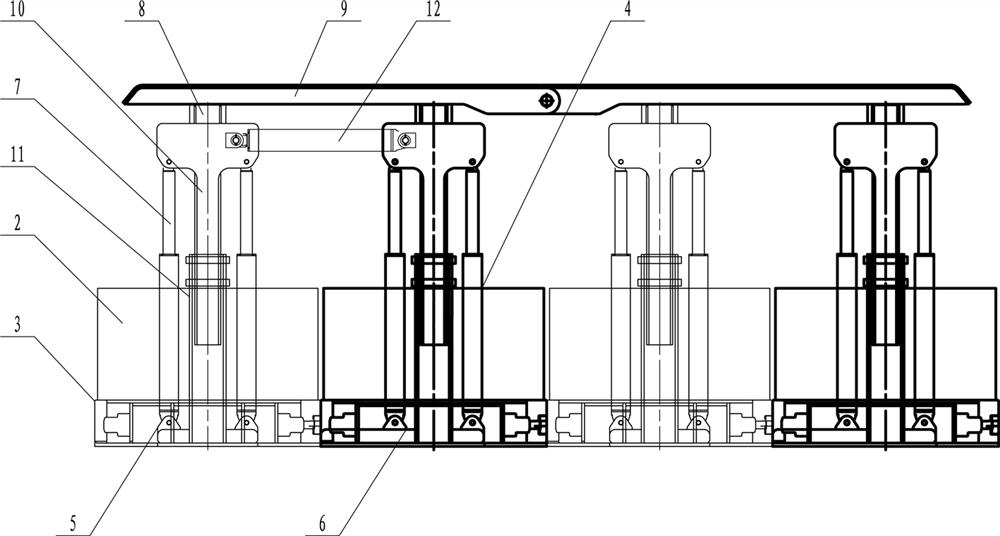

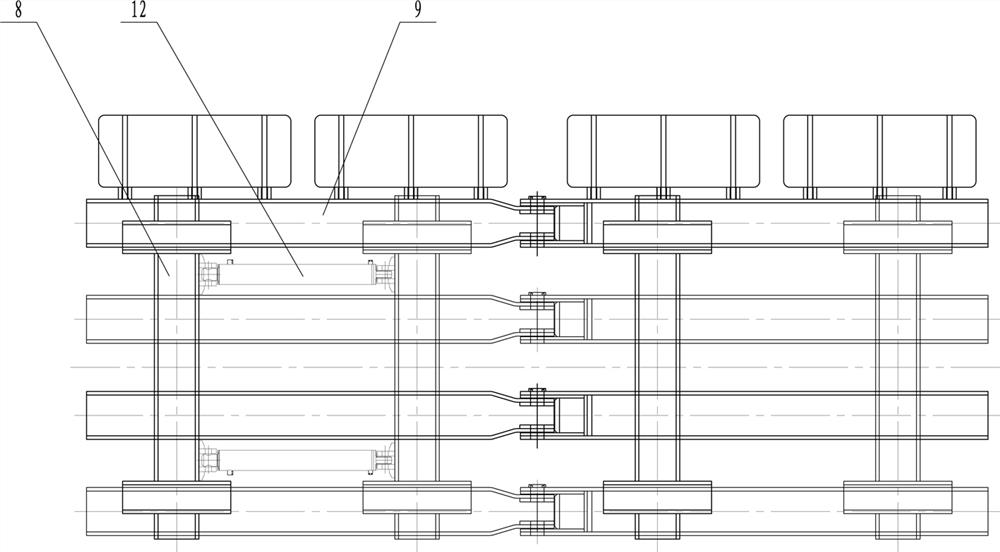

[0030] Such as Figure 1-Figure 4 As shown, a transport roadway support traveling mechanism includes an advanced support 1 and a transfer machine transport trough 2, the transfer machine transport trough 2 is an independent structure that removes the transfer machine self-moving mechanism, and the advanced support 1 includes a main frame 3 and Auxiliary frame 4, in the present embodiment, a pair of advanced support is made of four supports, and one or three supports form main frame, and two or four supports form sub-frame, ( figure 2 Among them, the thin line represents the main frame, and the thick line represents the sub-frame) both overlap and fit together, and the overall travel of the leading frame 1 is realized through the alternate travel of the main frame 3 and the sub-frame 4. The base 5 of the main frame and the The transfer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com