Fiber bragg grating hydrophone dragging array monitoring system

A fiber grating and monitoring system technology, which is applied to instruments, measuring devices, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of complex release and recovery systems, large installation space requirements, and heavy weight, so as to reduce system signal interference and realize The effect of digital transmission and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

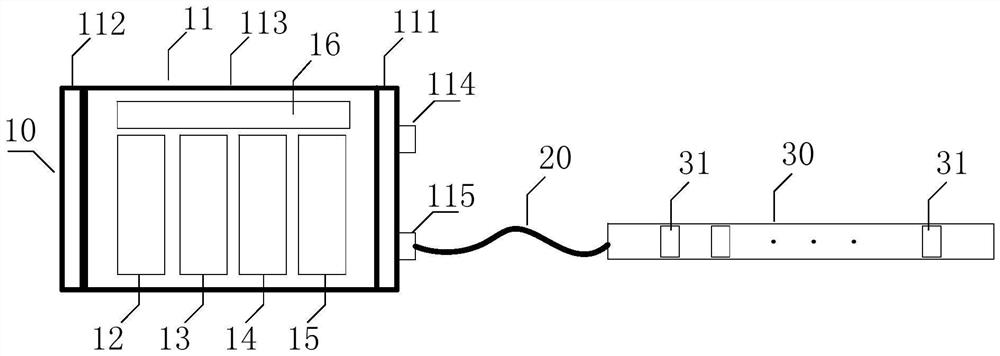

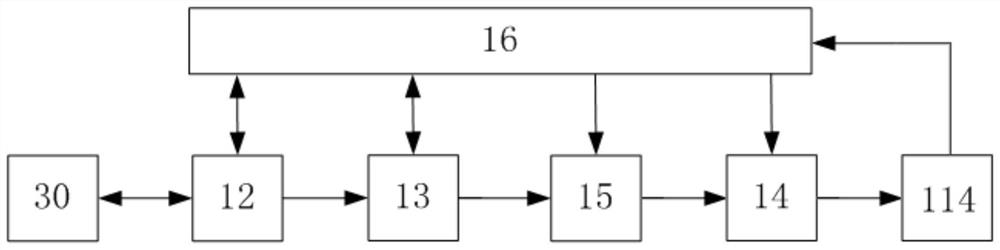

[0018] Example: as attached figure 1 As shown, this fiber grating hydrophone towed array monitoring system includes a watertight electronic cabin 10, a transmission optical cable 20 and a fiber grating towed line array 30. The watertight electronic cabin 10 has an outer casing 11 in a sealed structure, and the outer casing 11 includes The upper end cover 111, the lower end cover 112 and the barrel body 113, the barrel body 113 is a watertight metal cylinder, and the sealing ring is used between the barrel body 113, the upper end cover 111, and the lower end cover 112 to be watertight and fixed with screws; the upper end cover 111 is embedded with There is a power supply communication interface 114 and an optical cable transmission interface 115 . Several functional modules are loaded in the outer casing 11, and the functional modules include an optical transceiver module 12, a signal demodulation module 13, a signal processing module 14, a data storage module 15 and a power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com