Asphalt waterproof coiled material tearing performance detection method

A technology of bitumen waterproofing membrane and tearing performance, applied in the direction of measuring device, analyzing material, strength characteristics, etc., can solve the problems of falling off of waterproofing membrane and unable to fix asphalt waterproofing membrane, and achieve the effect of reducing the possibility of falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

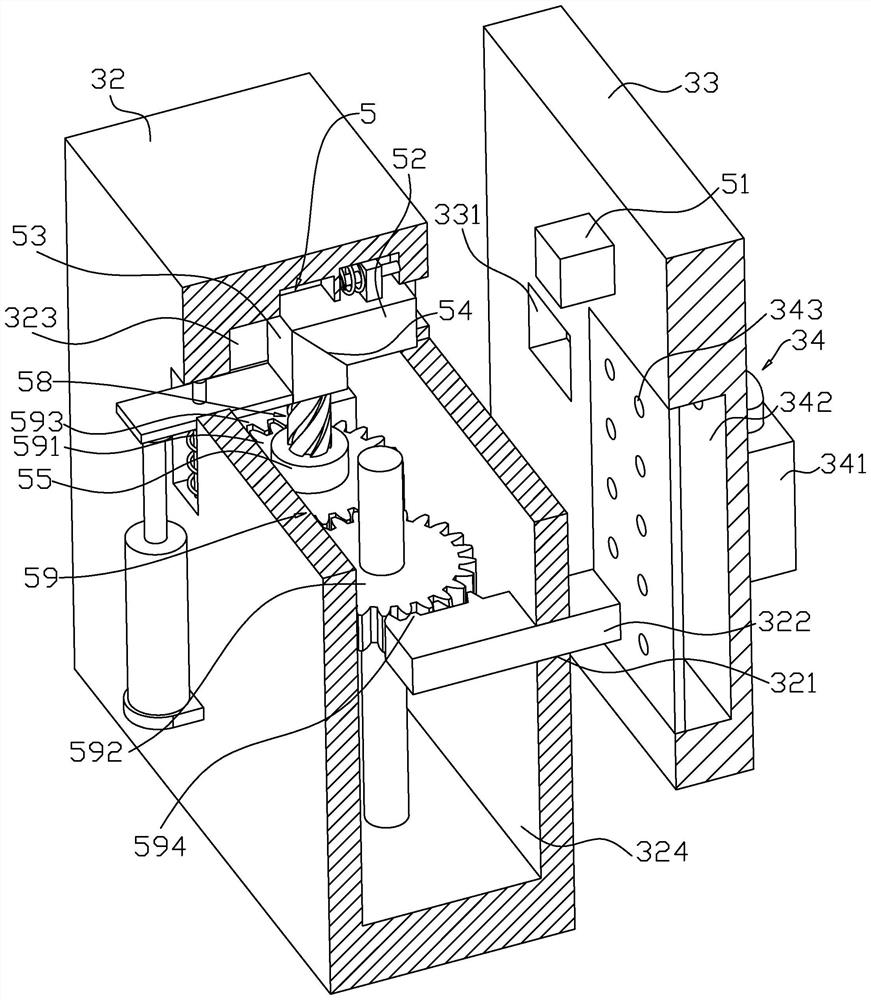

[0038] The following is attached Figure 1-5 The application is described in further detail.

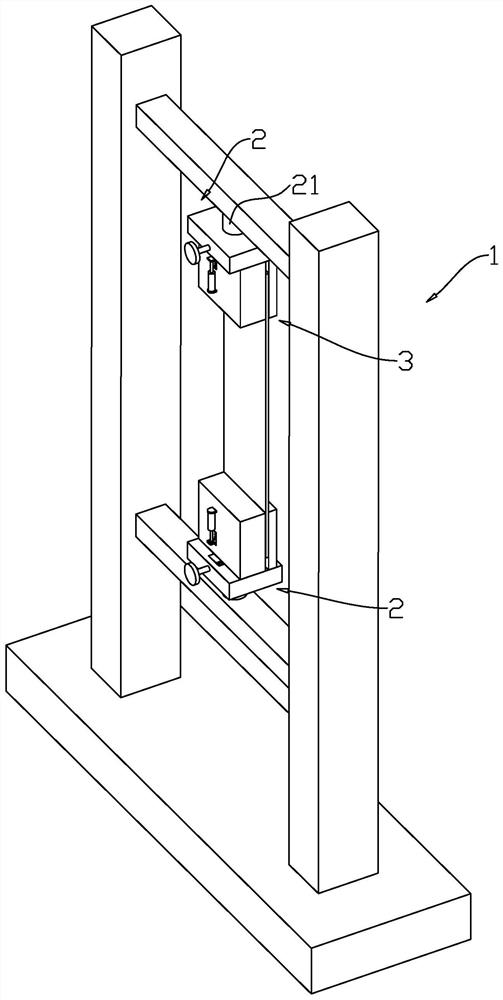

[0039] The embodiment of the present application discloses a method for testing the tearing performance of asphalt waterproof membrane, such as figure 1 with figure 2 shown, including the following steps:

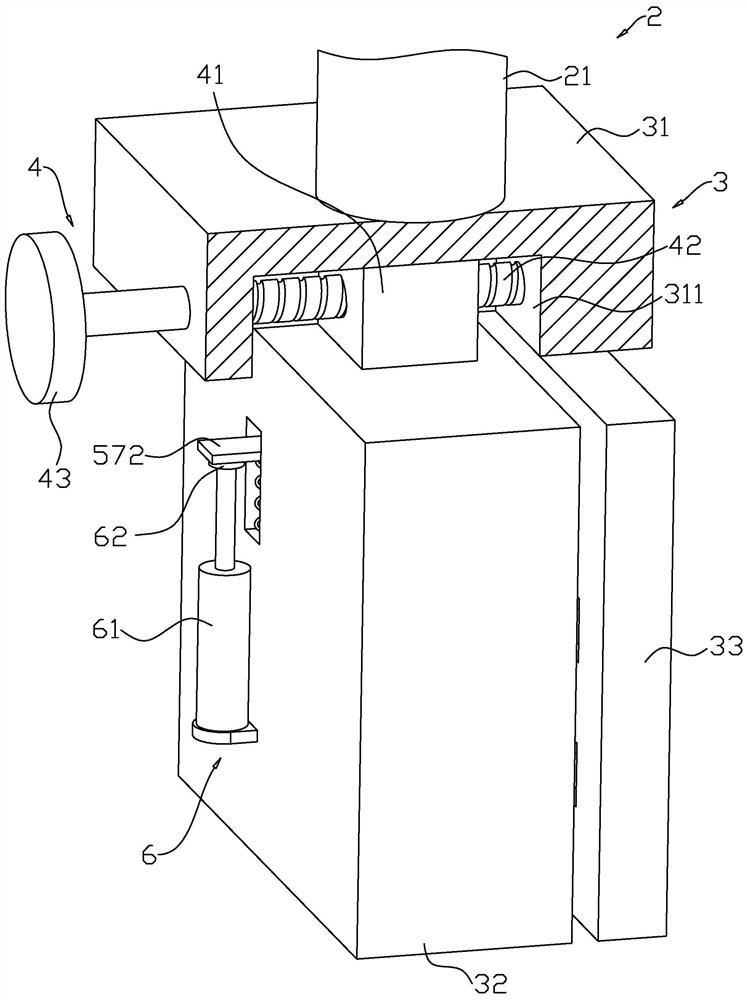

[0040] S1. Install two sets of clamping structures: two sets of clamping structures 2 are arranged oppositely, each set of clamping structures 2 includes a connecting block 21 and a clamping device 3 arranged at the bottom of the connecting block 21; the connecting block 21 is fixed by bolts to the asphalt waterproof membrane tearing performance testing machine 1, so that the installation of the clamping structure 2 can be completed;

[0041] S2. Install the asphalt waterproof coiled material: the clamping device 3 includes a horizontal plate 31 installed on the side wall of the connecting block 21, and the bottom of the horizontal plate 31 is provided with a movable plate 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com