A Nonlinear Substructure Method Applicable to Modeling Complex Large Flexible Aircraft

A nonlinear, aircraft technology, applied in the field of structural dynamics, can solve the problems of high modeling cost and low calculation efficiency, and achieve the effect of speeding up the design progress, reducing the amount of analysis and calculation, and improving the calculation and design efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

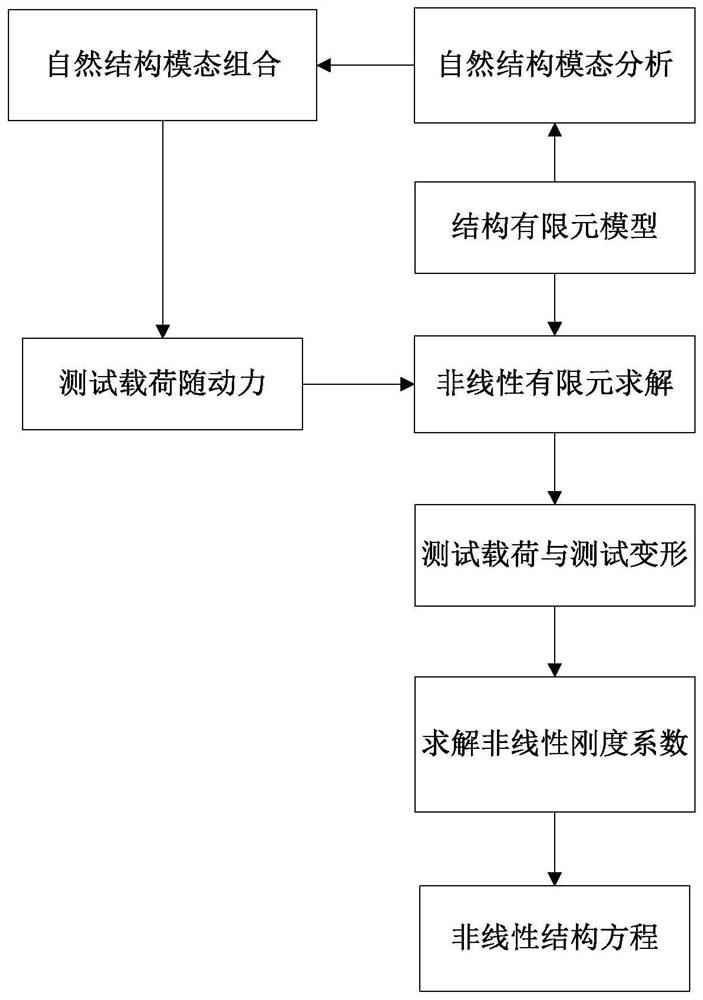

Method used

Image

Examples

Embodiment 1

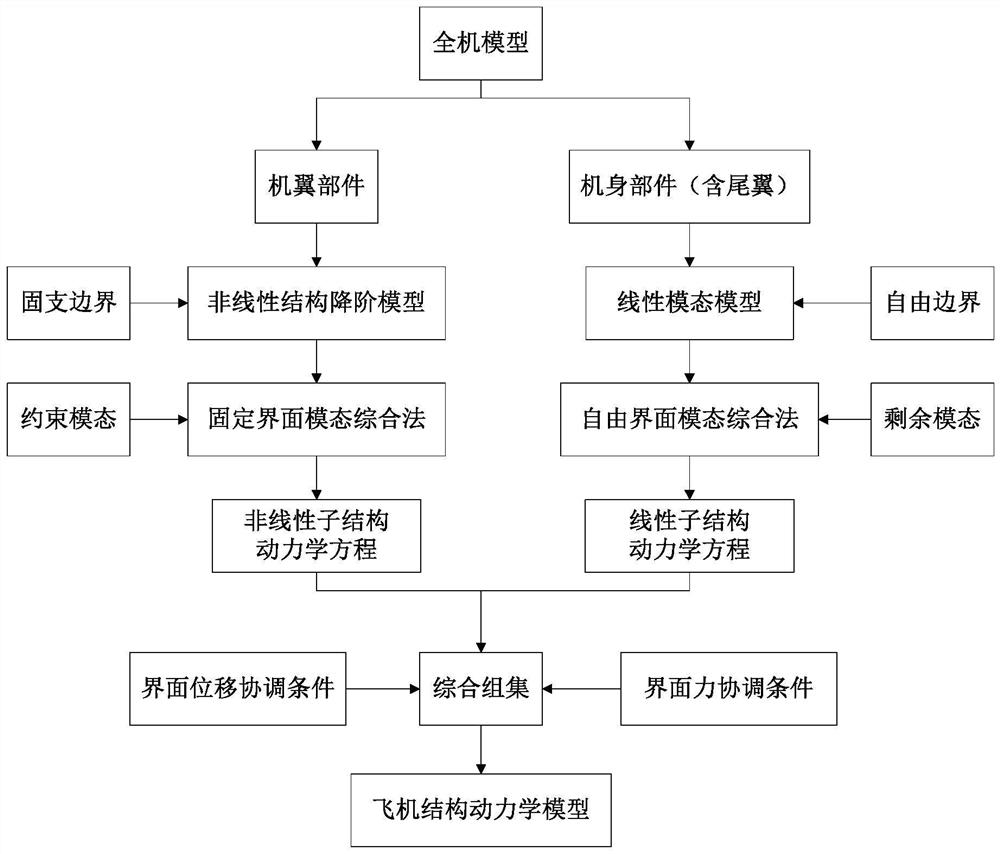

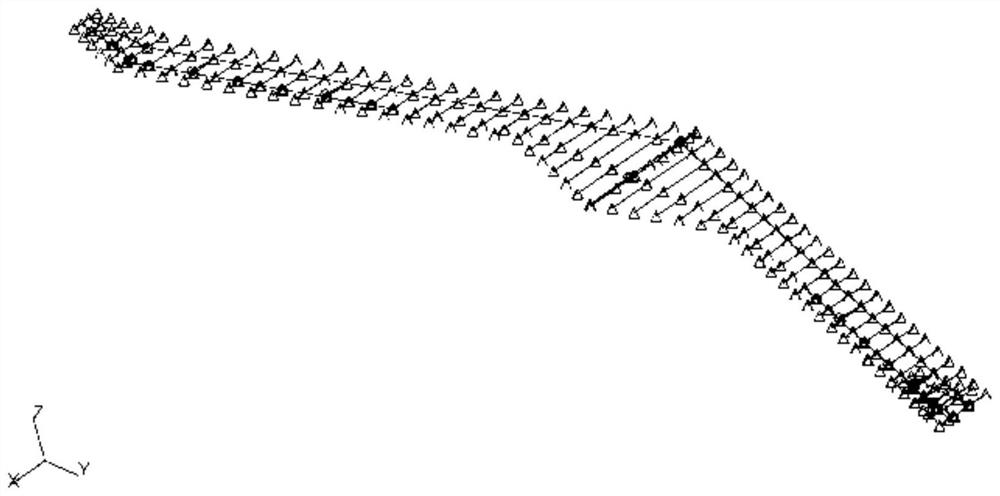

[0102] Using a large aspect ratio flying-wing drone model, the flying-wing drone is mainly composed of a central wing body fusion body and wings on both sides. The wing tip is a swept vertical tail with the same structure as the wing. There are two control surfaces on the trailing edge of each wing, which can control elevators, ailerons and flaps through differential / linkage between different control surfaces. Finite element models such as image 3 shown. The stiffness characteristics of the surface structure are simulated by a finite element elastic beam located at 35.8% of the chord length of the outer wing, and the mass characteristic distribution is simulated by several lumped mass elements located on the wing surface. The wingtip vertical tail also adopts the same structural unit form. Some parameters of the model are shown in Table 1. The process of building a large flexible aircraft structure model is as follows: figure 2 shown.

[0103] Table 1 Parameters of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com