Frequency tunable microstrip patch antenna based on half-cut technology

A technology of microstrip patch antenna and microstrip patch, which is applied in the directions of antenna grounding device, antenna grounding switch structure connection, radiation element structure, etc., and can solve the problem that variable capacitance has a great influence on antenna radiation performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

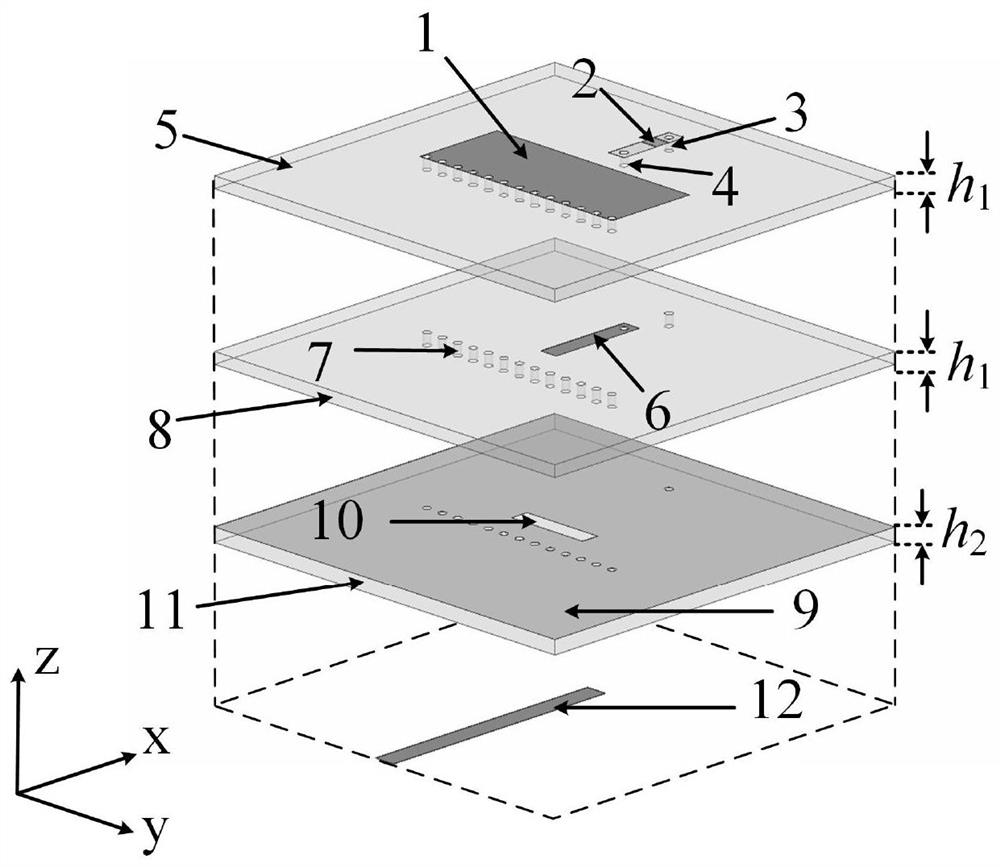

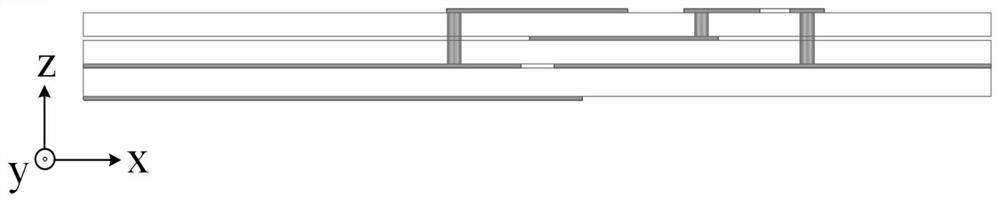

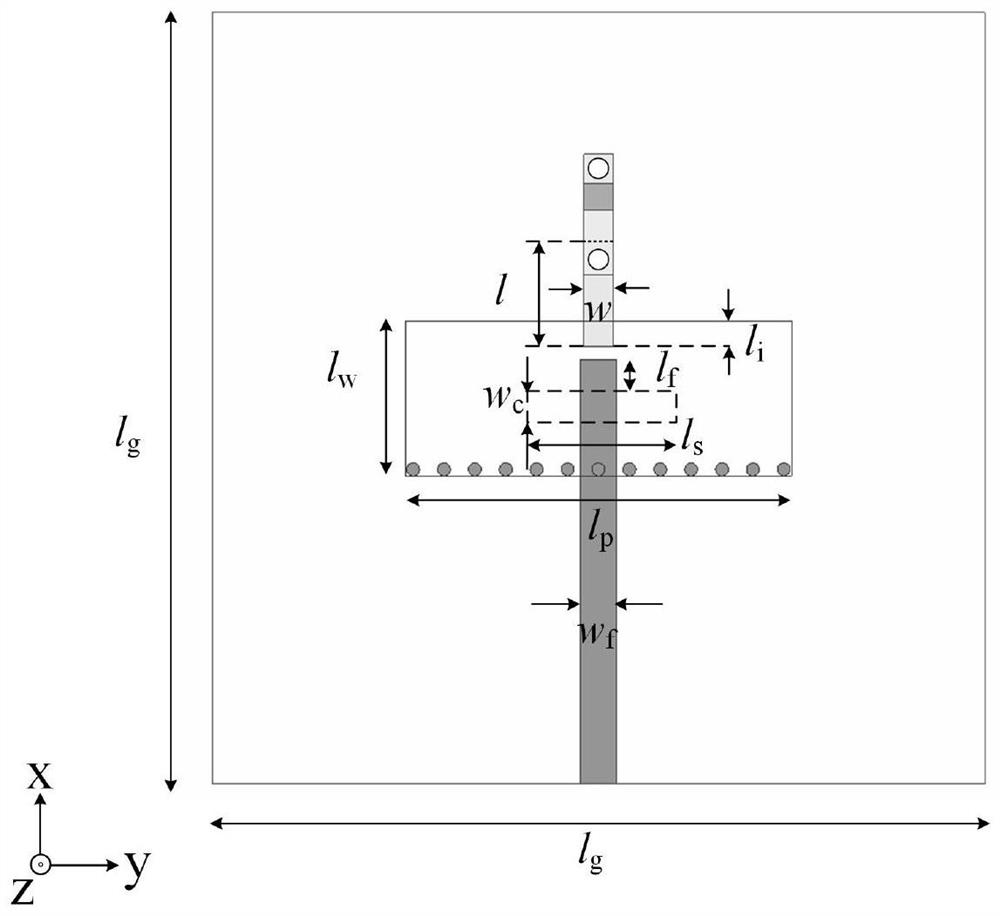

[0019] Such as Figure 1 to Figure 3 As shown, the frequency-tunable microstrip antenna with non-contact variable capacitance loading in this embodiment includes a bottom substrate 11 , a microstrip patch resonator and a microstrip feeder 12 respectively disposed on the upper and lower surfaces of the bottom substrate 11 . The microstrip patch resonator includes a metal reflective floor 9 , an intermediate substrate 8 , a top substrate 5 and a microstrip patch 1 which are sequentially stacked from bottom to top. The microstrip patch 1 is a rectangular microstrip patch, and is disposed in the center of the top substrate 5 . There is a microstrip line 6 for frequency tuning between the top substrate 5 and the middle substrate 8 , and the microstrip line 6 for frequency tuning is arranged along the centerline of the microstrip patch 1 . The micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com