Method for improving quality factor of micro-resonator by using superposition of orthogonal mode, and realizing device thereof

A micro-resonator, quality factor technology, applied in impedance networks, electrical components, etc., can solve the problems of no reported quality factor, increase the complexity of the resonator system, disadvantageous device miniaturization and integration, etc. Long-life, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

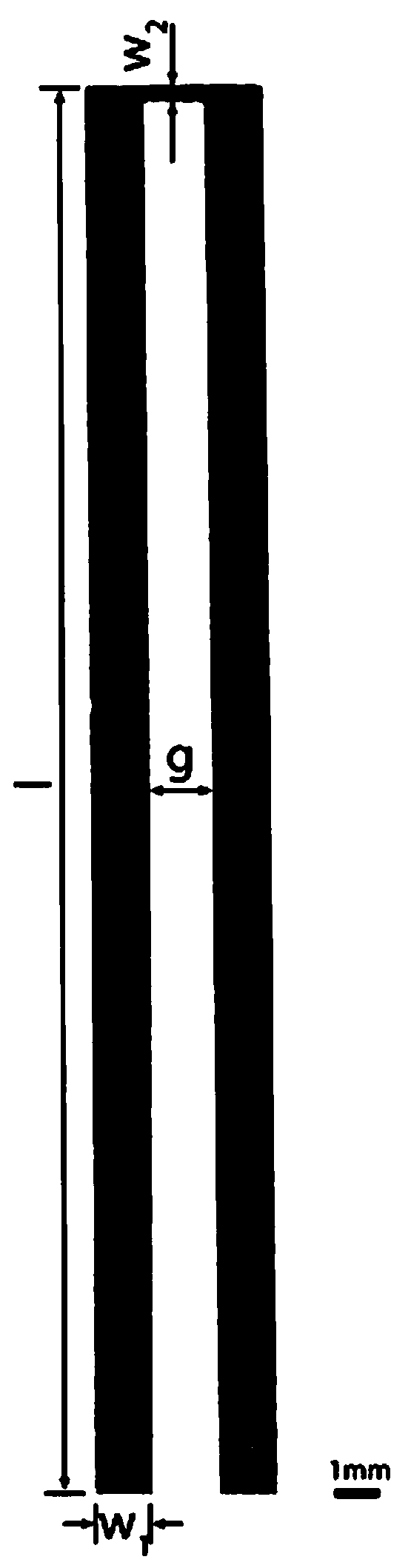

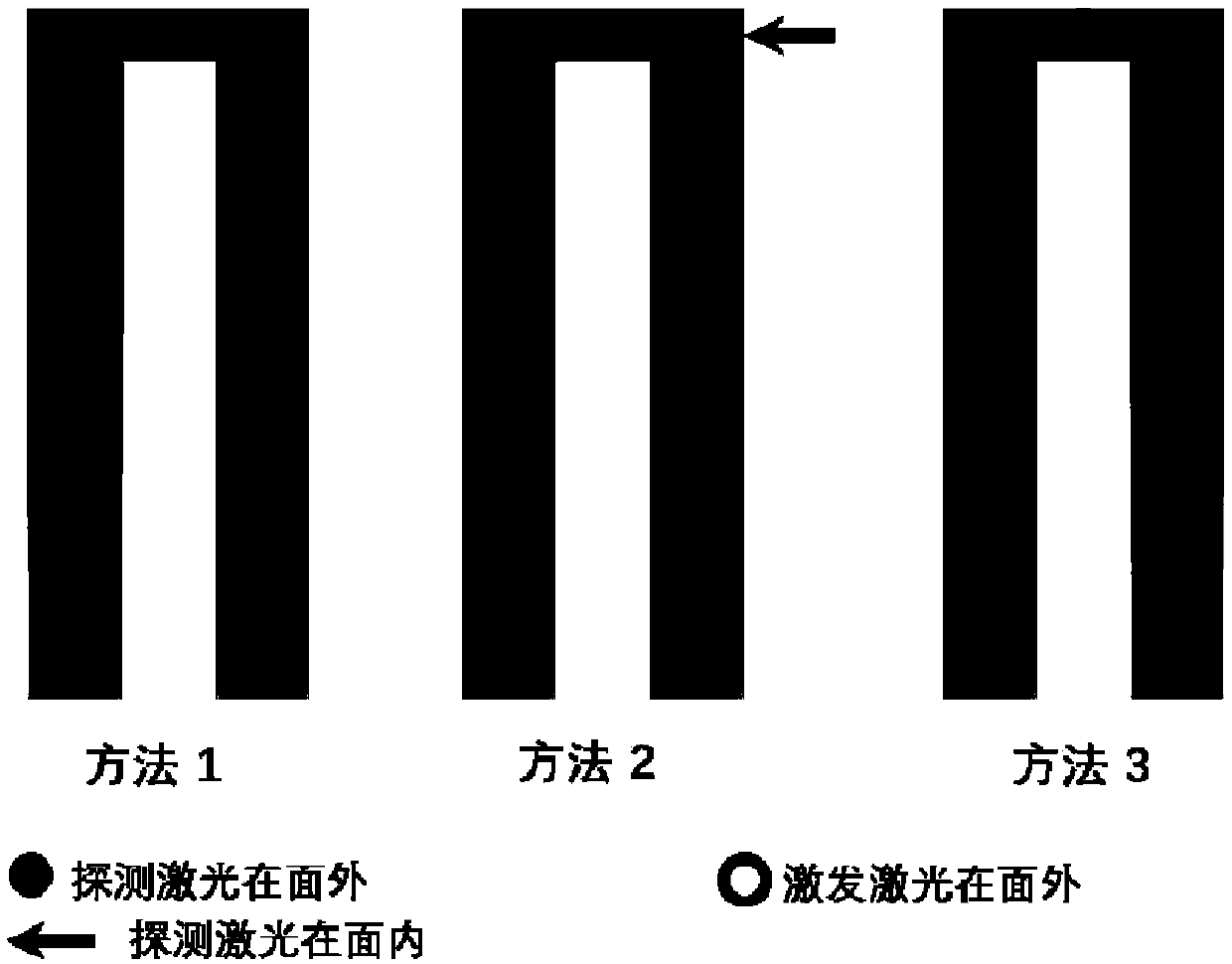

[0057] A method for improving the quality factor of a microresonator by superposition of orthogonal modes, the microresonator comprising two cantilevers and a beam connecting the two cantilevers, comprising the following steps:

[0058] (1) Simultaneous excitation and measurement of the orthogonal mode: focus the modulated laser on the middle of the bridge of the microresonator, that is, a rectangular area with a length of 1.25 mm and a width of 0.2 mm in the middle of the beam, so that it vibrates and excites Two mutually perpendicular orthogonal modes of the resonator; the wavelength of the modulated pulse laser is 375nm; this wavelength is in the band with the maximum absorption rate of SUS304 stainless steel.

[0059] Modulated laser light is shone onto the bridges of the microresonators to excite them to vibrate. Laser irradiation on the surface of the microresonator creates a temperature gradient through its thickness and causes it to bend. When a sinusoidal signal is i...

Embodiment 2

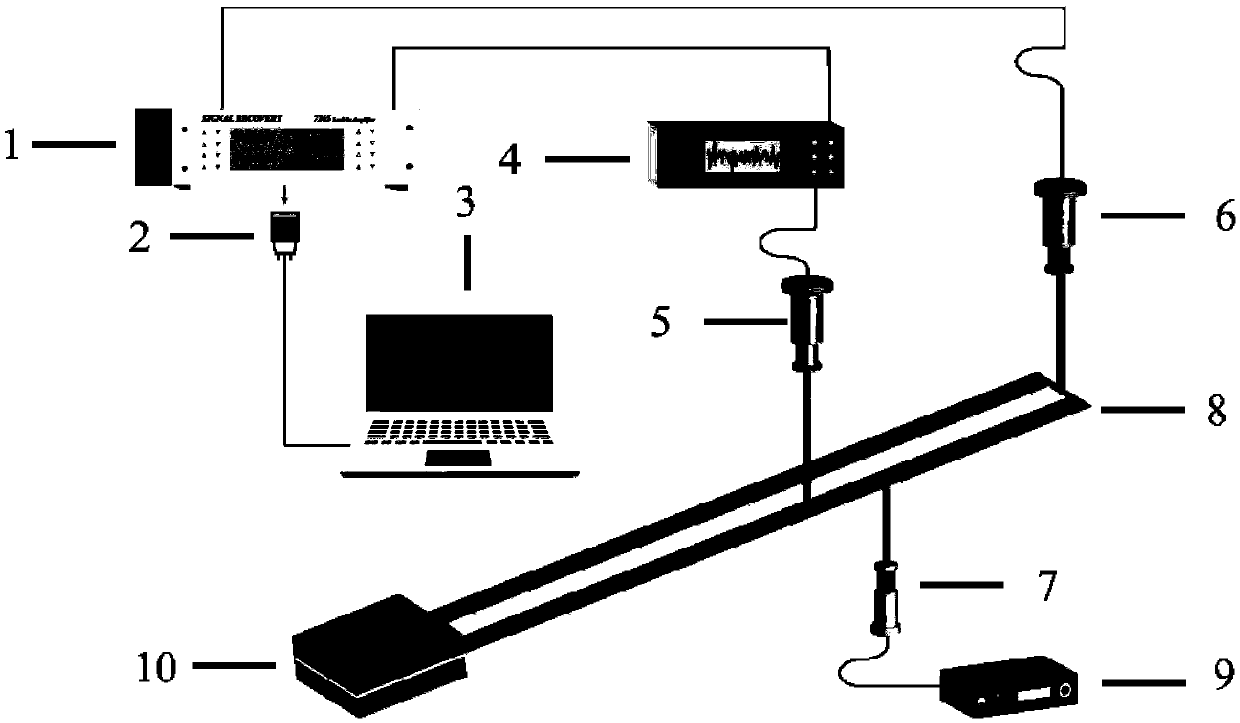

[0079] A realization device of a method for improving the quality factor of a microresonator by using the superposition of orthogonal modes described in Embodiment 1, such as figure 1 As shown, it includes a computer 3, a data acquisition card 2, a lock-in amplifier 1, a laser vibrometer controller 4, a modulation laser 6, a laser vibrometer probe 5, an adjustable power continuous laser 7, and a continuous laser power controller 9;

[0080] Computer 3, data acquisition card 2, lock-in amplifier 1 are connected sequentially, lock-in amplifier 1, laser vibrometer controller 4, laser vibrometer probe 5 are connected sequentially, lock-in amplifier 1 is connected to modulated laser 6, continuous laser power control Device 9 is connected to adjustable power continuous laser 7;

[0081] During use, the modulation laser 6 is connected to the center of the bridge of the microresonator, the laser vibrometer probe 5 is aligned with a cantilever of the microresonator, and the adjustable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com