Low-energy high-fiber sweet potato cake double-layer automatic stacking device and forming technology

A technology for high-fiber sweet potatoes and cakes, which is applied in the directions of filling baked goods, baking, and baked food processing, can solve problems such as single function, cake offset and tilt, and achieve the effect of improving production quality and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

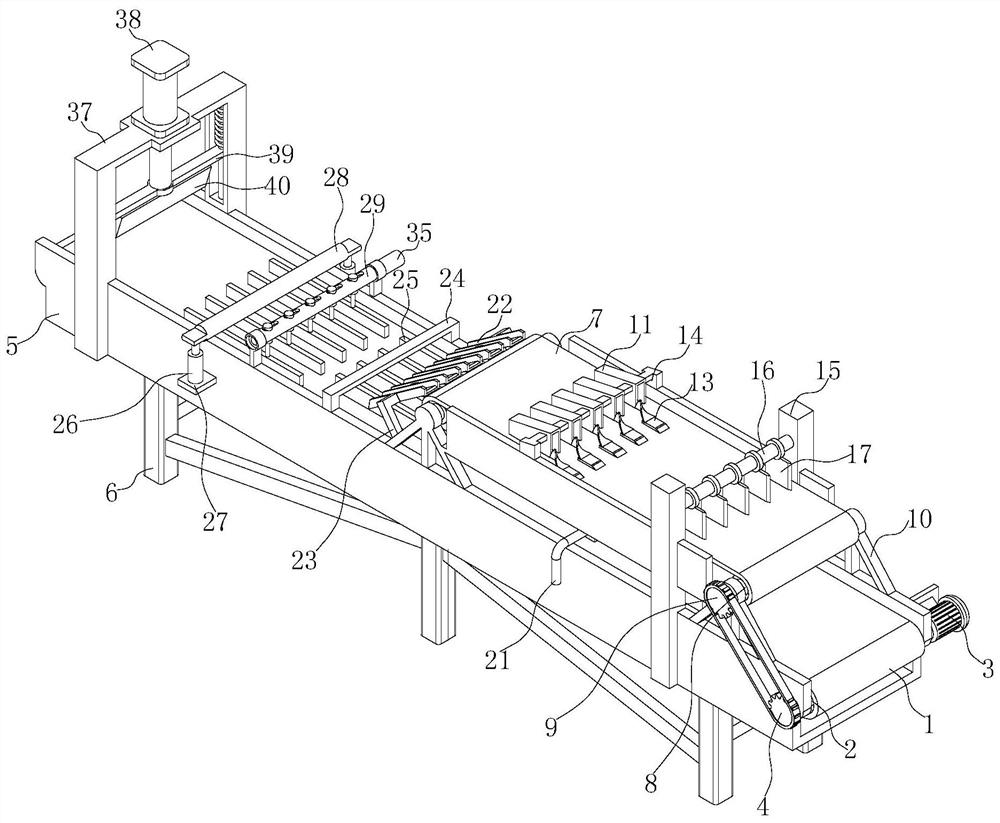

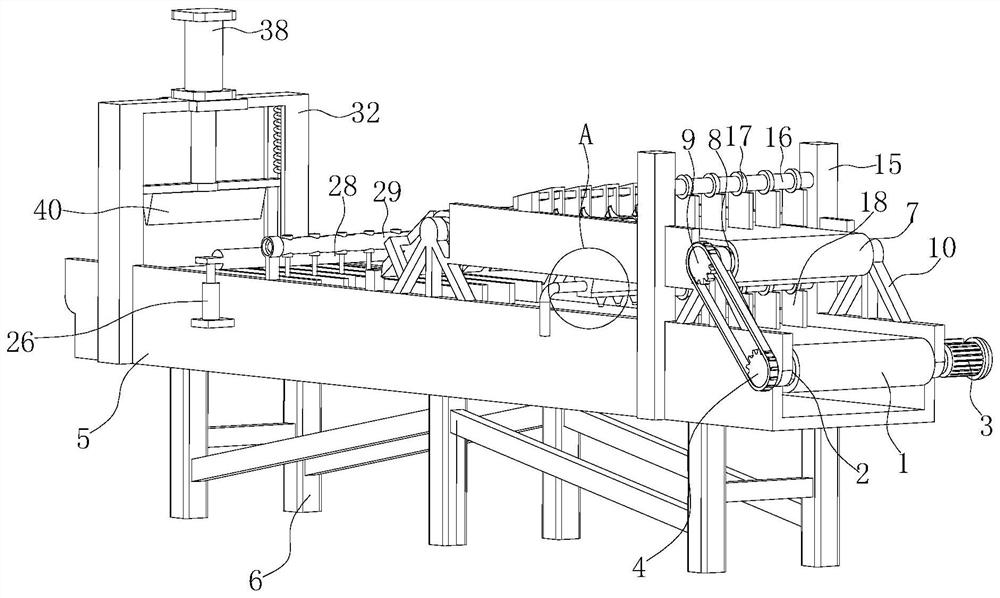

[0040] see Figure 1-7 , the present invention provides a technical solution: a double-layer automatic stacking device for low-energy and high-fiber sweet potato cakes, comprising a first conveyor belt 1, a mounting plate 5 and a second conveyor belt 7, both ends of the first conveyor belt 1 are socketed with a second A drive roller 2, two first drive rollers 2 are evenly and symmetrically socketed inside the installation plate 5, a driving motor 3 is fixedly installed on the back of one of the first drive rollers 2, and a mounting frame 6 is fixedly installed on the bottom of the installation plate 5 , both ends of the second conveyor belt 7 are sleeved with a second transmission roller 8, the front of one of the two first transmission rollers 2 is fixedly equipped with a driving gear 4, and the front of the other second transmission roller 8 is fixedly installed with a Driven gear 9, driving gear 4 is connected with driven gear 9 by chain, and the front and the back of two s...

Embodiment 2

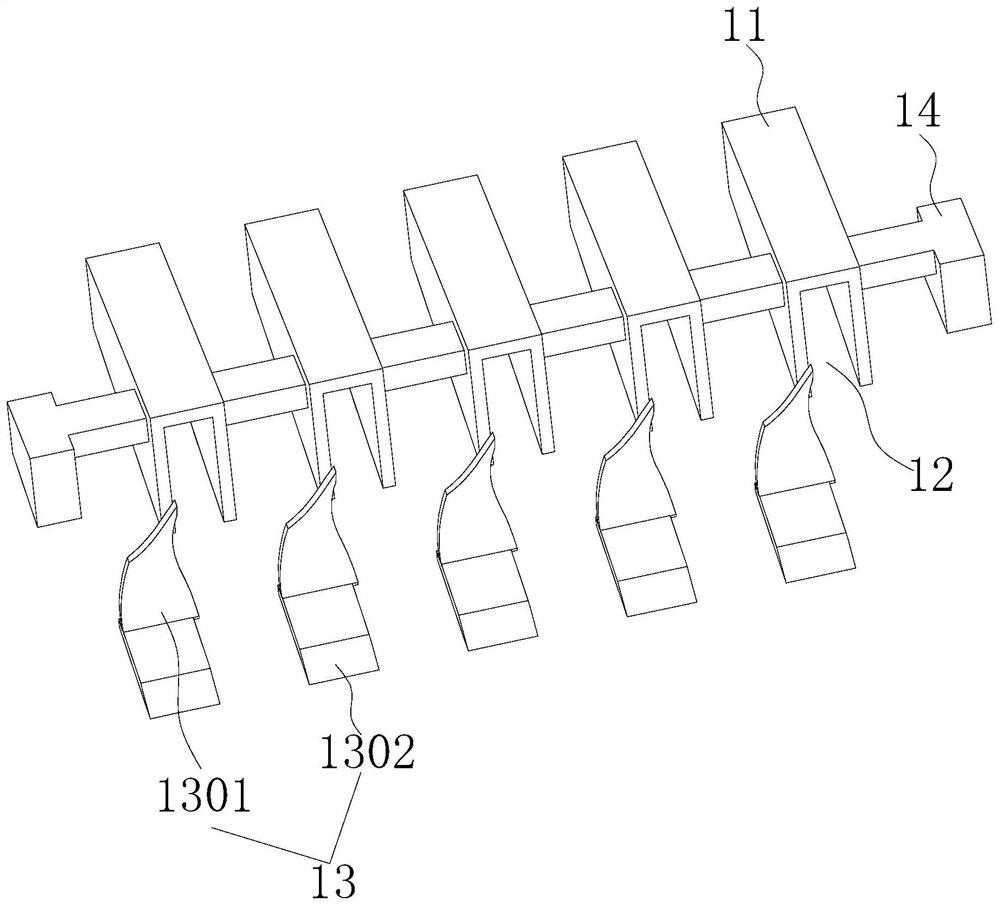

[0043] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the turning device 13 includes a turning plate 1301 and a flat plate 1302, the turning plate 1301 and the flat plate 1302 are fixedly connected, and the side of the flat plate 1302 away from the turning plate 1301 is a slope , and the bottom of the flat plate 1302 is attached to the top of the second conveyor belt 7 .

[0044] In this embodiment, the side of the flip plate 1301 away from the flat plate 1302 is fixedly connected to the guide cylinder 11, and the flipping device 13 composed of the flip plate 1301 and the flat plate 1302 is provided, and the strip-shaped cake is passed through the flip plate 1301. Flip 180°, so that the burnt layer of the strip cake on the top of the second conveyor belt 17 faces upwards, and then automatically overlap with the cake on the top of the first conveyor belt 1. This method is more efficient than manual stacking, and ...

Embodiment 3

[0046] Such as Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom of the first connecting frame 10 is fixedly installed with a core injection tube 19, and the bottom of the core injection tube 19 is fixed with a core injection head 20 , One side of the injection tube 19 communicates with an injection pipe 21 .

[0047] In this embodiment, through the set injection tube 19, injection head 20 and injection pipe 21, the filling pump is used to inject the core into the injection tube 21, and the sandwich is transported to the inside of the injection tube 19 through the injection tube 21, and is injected by the injection tube 21. The heart 20 injects the filling into the cake, which increases the function of the device, is beneficial to the production of the cake, and is also suitable for cakes that do not need to inject the filling.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap