A core manufacturing method for increased flow conductivity and fit

A manufacturing method and core technology, applied in medical science, absorbent pads, underwear, etc., can solve the problems of wearer discomfort, increased risk of urine leakage, poor absorption effect, etc., and achieve improved production efficiency, small position deviation, and absorption powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

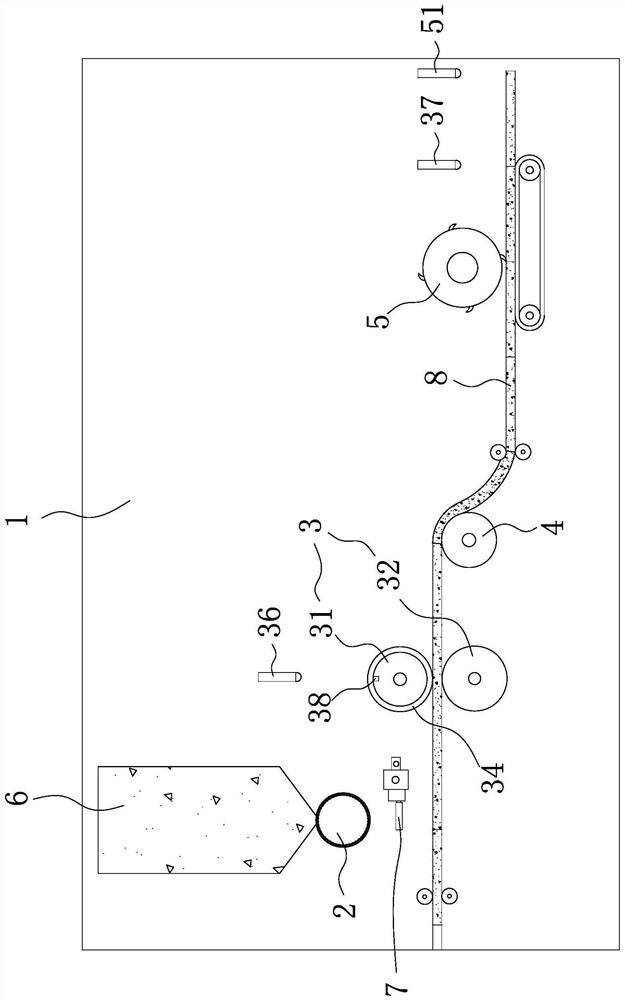

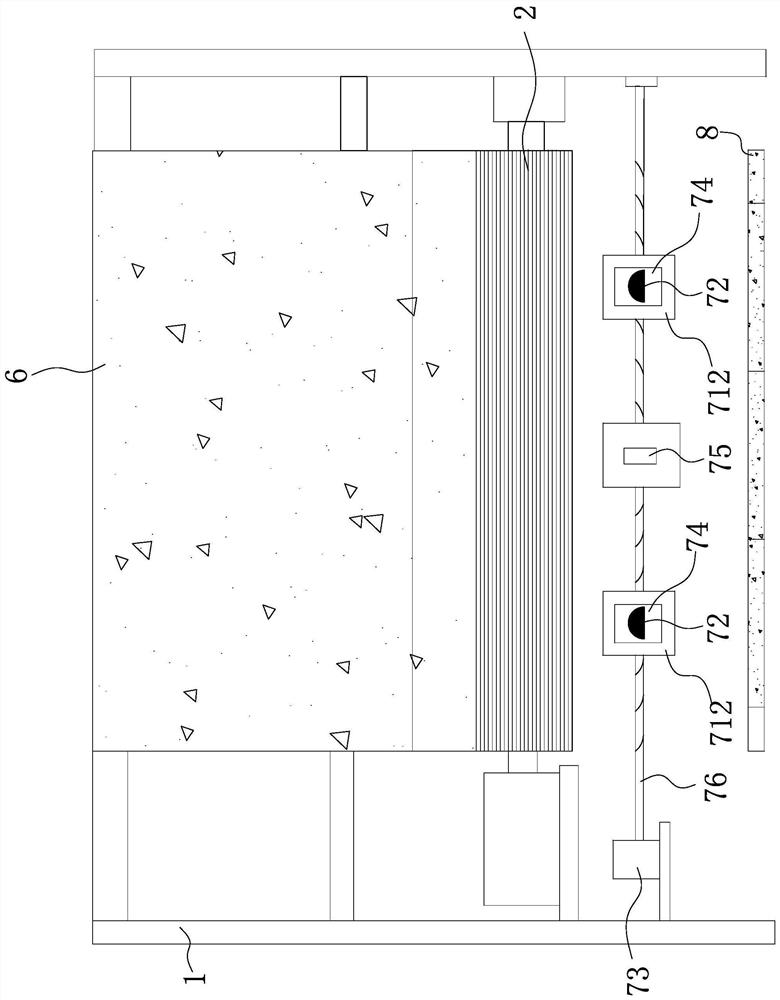

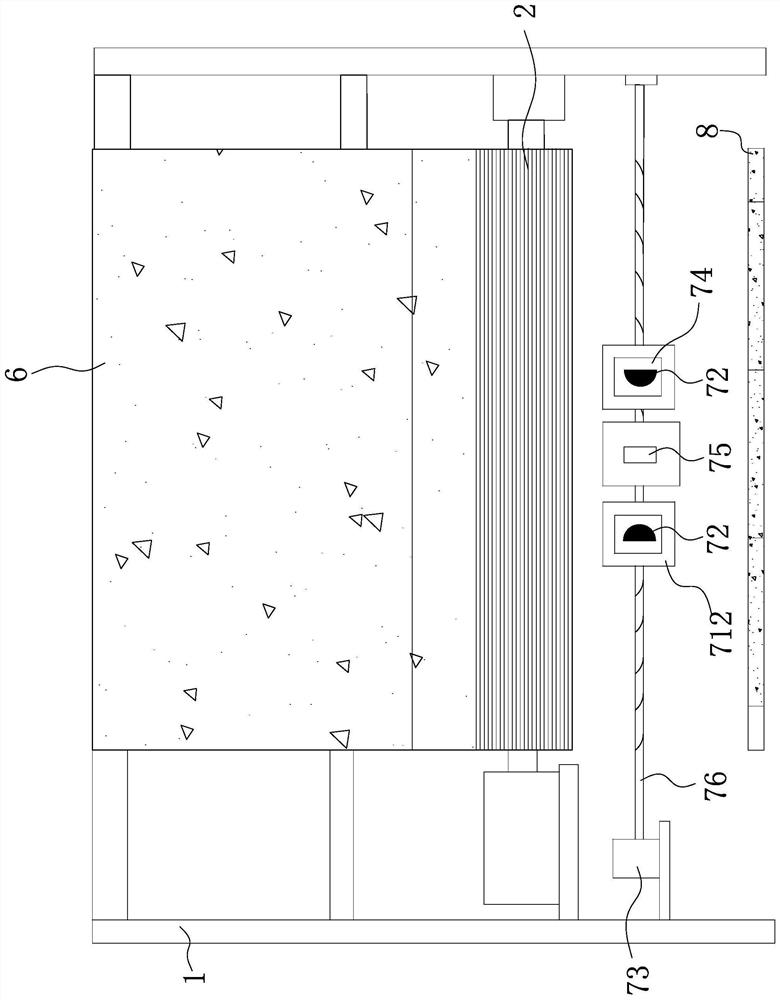

[0031] refer to Figure 1 to Figure 7, the present embodiment provides a core body manufacturing method with increased diversion and fit, including a frame 1, on which a blanking mechanism 2, a pressing mechanism 3, a conveying mechanism 4, and a cutter mechanism are sequentially arranged along the conveying direction 5. There is a material storage device 6 above the unloading mechanism 2, the lower end of the storage device 6 is provided with a discharge port, the unloading mechanism 2 is located at the lower end of the discharge port, and the frame 1 is provided with a baffle under the unloading mechanism 2 Mechanism 7, baffle plate mechanism 7 comprises guide mechanism 71 that is located on frame 1, two baffle plates 72 that move along guide mechanism 71, the first driving mechanism 73 that drives transmission baffle plate 72 to move, and guide me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com