Desulfurization reaction tower capable of absorbing chemicals

A desulfurization tower and reaction tower technology, which is applied to the field of desulfurization reaction towers for internal absorption of chemicals, can solve problems such as cost increase, increase in desulfurization tower burden, and sulfur content reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

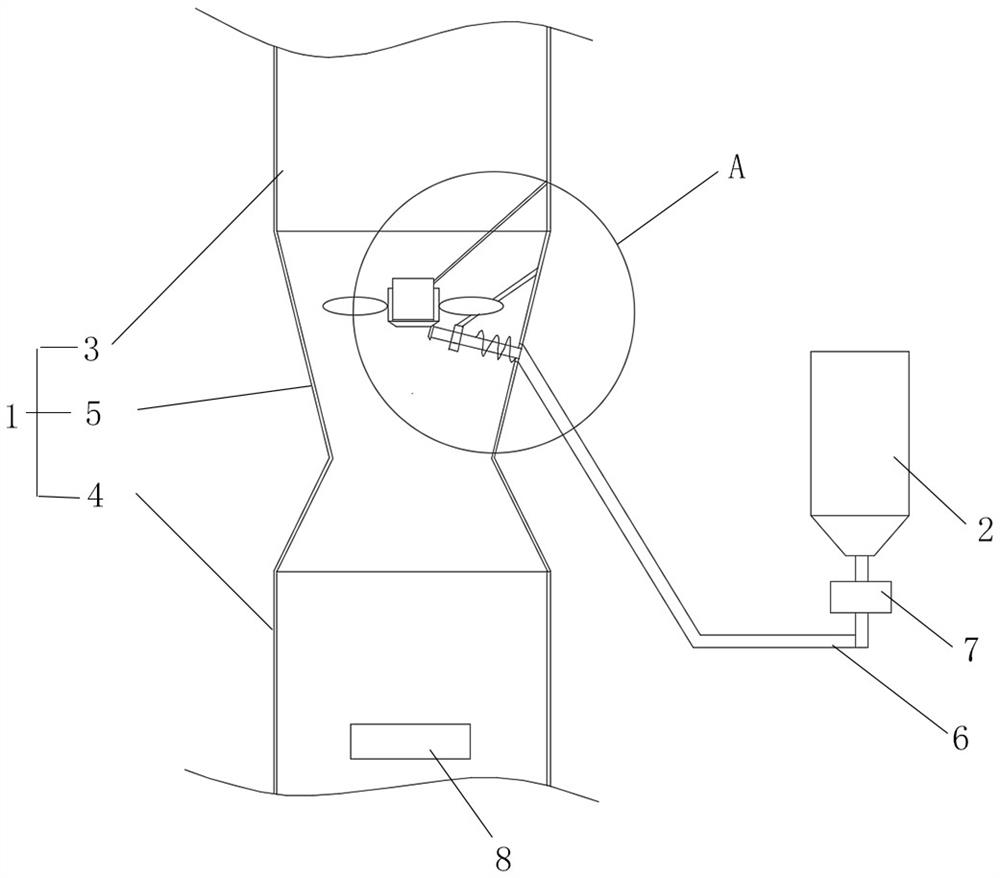

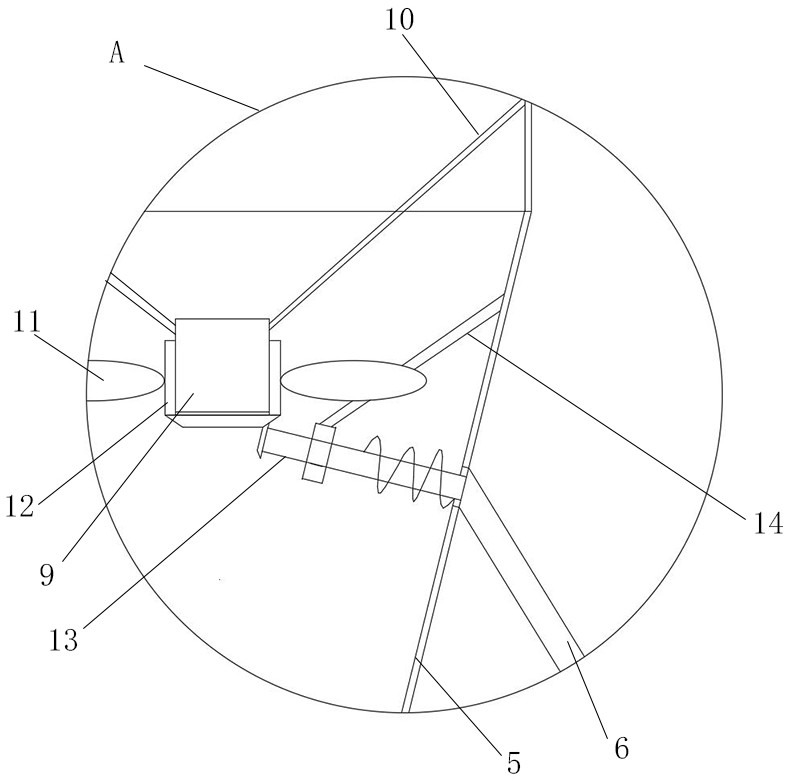

[0014] As shown in the figure: a desulfurization reaction tower for systemically absorbing chemicals, including a desulfurization tower 1 for flue gas desulfurization reaction and a silo 2 for providing catalytic materials to the desulfurization tower 1. The desulfurization tower 1 includes an integrated structure The upper tower section 3, the lower tower section 4 and the suction section 5, the upper tower section 3 and the lower tower section 4 are hollow cylinders, preferably, the upper tower section 3 and the lower tower section 4 are hollow cylinders , the two are coaxial and the bottom end of the lower tower section 4 is connected to the outlet of the flue gas to be treated. The inside of the desulfurization tower 1 is located in the lower tower section 4. A smoke detector 8 is installed, and the flue gas detector 8 is used to detect the flue gas The sulfur content in; the suction section 5 is vertically arranged and its bottom and top are fixedly connected to the top of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap