New material processing and mixing treatment device

A mixing treatment and mixing device technology, which is applied in the field of new material processing and mixing treatment devices, can solve the problems of inability to separate the reaction liquid in the lower layer, low reaction rate, uneven stirring of the stirring device, etc., so as to improve the primary reaction rate and improve the treatment effect , blending speed for fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

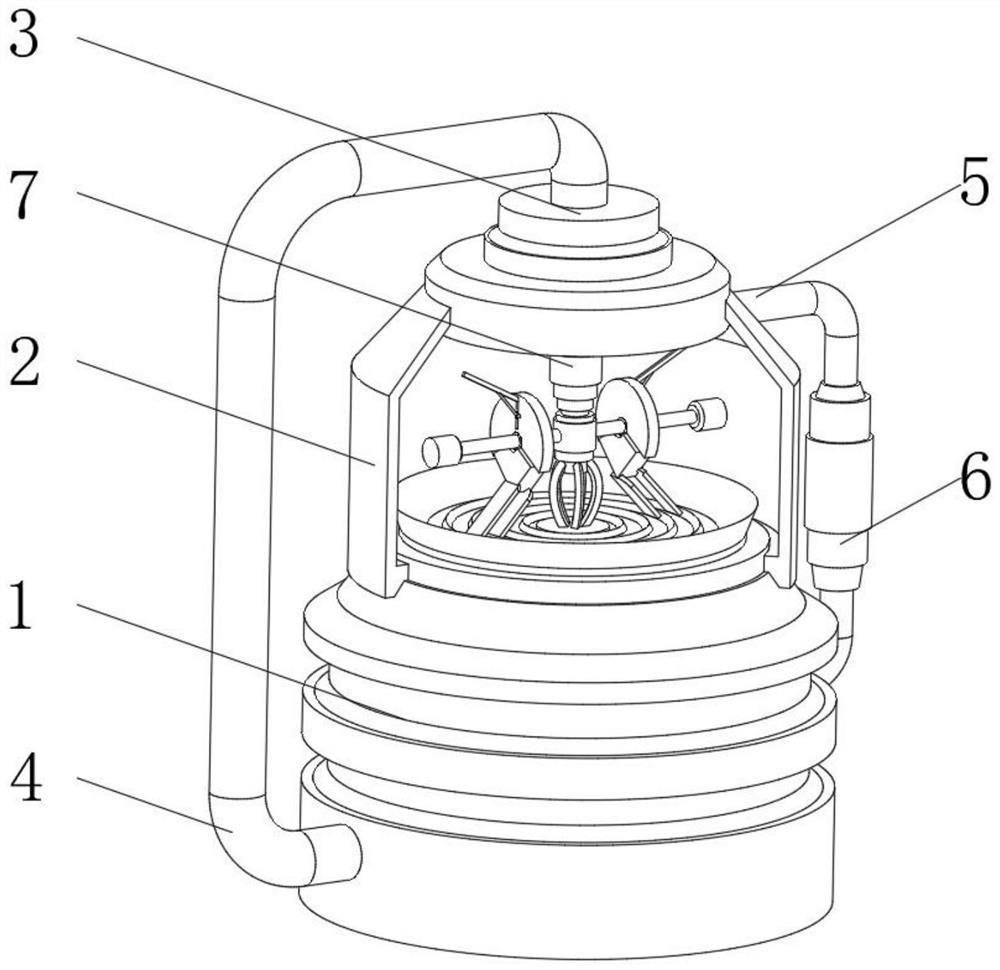

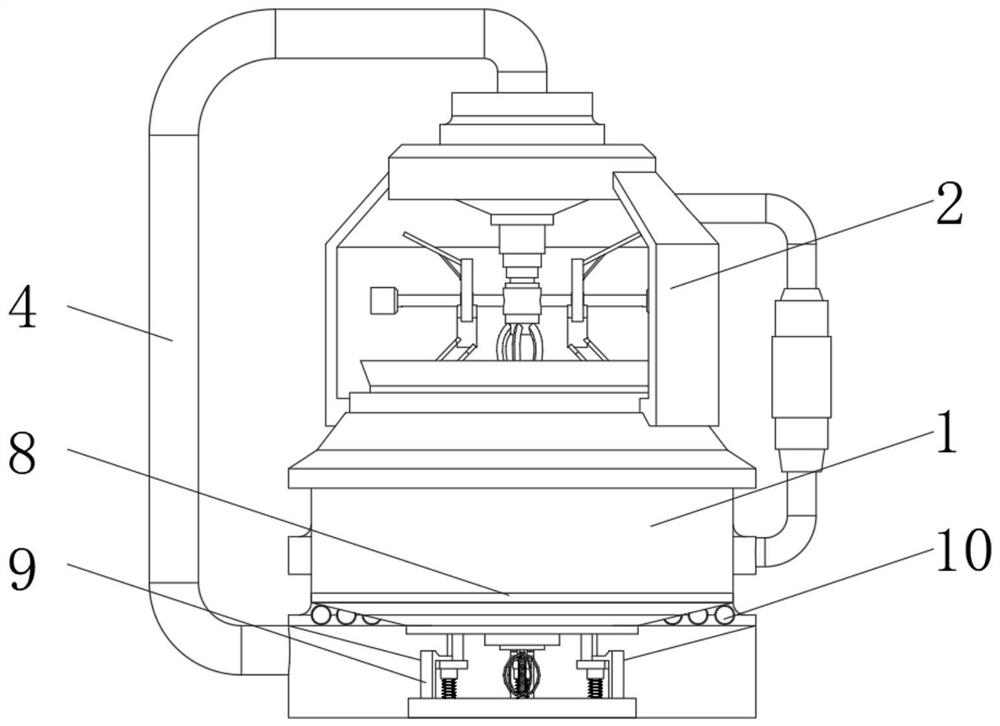

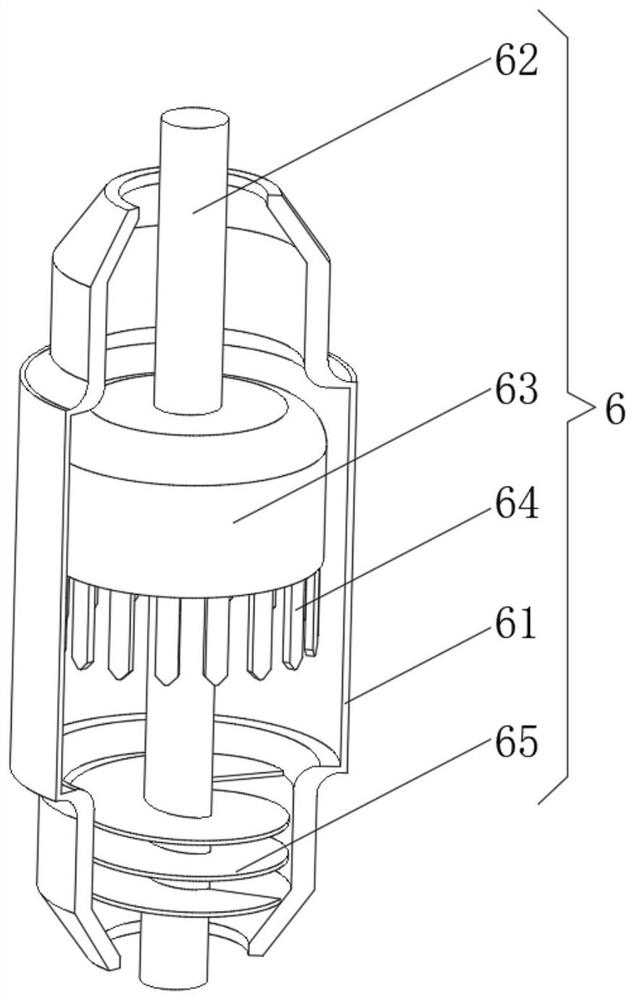

[0033] see Figure 1-4, the present invention provides a technical solution: a new material processing mixing treatment device, including a reaction tank 1 and a mixing treatment tank 2, the top of the mixing treatment tank 2 is provided with a top cover 3, and the top of the top cover 3 is connected to the bottom side of the reaction tank 1 A connection air guide pipe 4 is installed between them, a return air pipe 5 is installed between the top side of the reaction tank 1 and the upper side of the mixing treatment tank 2, a filtering self-generating device 6 is installed in the middle of the return air pipe 5, and a mixing tank 2 is installed inside. Device 7, a reaction chamber is provided inside the reaction tank 1, a pressure trigger device 9 is provided at the bottom of the reaction tank 1, a sedimentation liquid chassis 8 is provided on the inner side of the reaction chamber, and an outer discharge hole 10 is provided on the outer ring side of the reaction tank 1, Outer ...

Embodiment example 2

[0038] see Figure 1-6 , on the basis of the first embodiment, the present invention provides a technical solution: the pressure trigger device 9 includes a support base 91 and an installation top seat 92, an elastic support inner frame 93 is installed between the support base 91 and the installation top seat 92, and supports The base 91 top is provided with a side magnetic frame 94, and the top frame 92 bottom is provided with an upper frame 95, and a supporting spring bar 96 is provided between the upper frame 95 bottom and the supporting base 91, and the upper frame 95 is positioned at the side magnetic frame 94 below.

[0039] Both the side magnetic frame 94 and the upper frame 95 adopt L-shaped frames, and the positions corresponding to the side magnetic frame 94 and the upper frame 95 are set as opposite magnetic poles. After the reactant reacts continuously inside the device, the internal air pressure gradually increases. When the air pressure Greater than the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com