Preparation method of wafer locking ring

A technology of locking rings and wafers, which is applied in the direction of manufacturing tools, heat treatment equipment, metal processing equipment, etc., can solve problems such as difficult control of flatness, achieve the effects of optimizing microstructure, eliminating looseness in the as-cast state, and satisfying mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

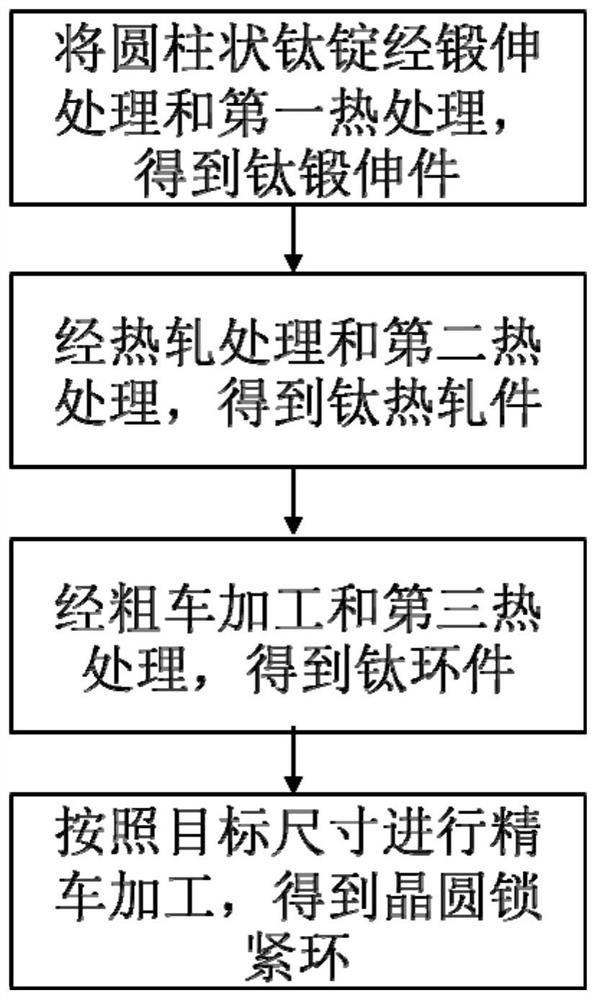

[0068] Such as image 3 As shown, the preparation method of the wafer locking ring of the present invention comprises the steps:

[0069] (1) Forging and stretching the cylindrical titanium ingot, and then performing the first heat treatment to obtain a titanium forging and stretching piece;

[0070] (2) hot-rolling the titanium forgings described in step (1), and then performing a second heat treatment to obtain a titanium hot-rolled piece;

[0071] (3) hollow out the central part of the titanium hot-rolled piece described in step (2) through rough turning, and then carry out the third heat treatment to obtain the titanium ring;

[0072] (4) Finish turning the titanium ring in step (3) according to the target size to obtain a wafer locking ring.

Embodiment 1

[0074] This embodiment provides a method for preparing a wafer locking ring, the preparation method comprising the following steps:

[0075] (1) Prepare a cylindrical titanium ingot with a purity of 99.9%, a diameter of 180mm, and a length of 120mm, and carry out forging and stretching at 950°C. Each forging and stretching process is first drawn according to the drawing and forging ratio of 1.66, and then Upsetting is carried out according to the upsetting forging ratio of 2.22, water cooling is repeated twice, and then the first heat treatment is carried out at 650°C for 120 minutes, and titanium forgings are obtained after air cooling;

[0076] (1') The titanium forging parts described in step (1) are subjected to re-stretching treatment at 800 ° C. Each re-stretching treatment is first drawn according to the elongation forging ratio of 2, and then according to the upsetting forging ratio Upsetting for 2.22, repeated 2 times, water cooling, and then the fourth heat treatment...

Embodiment 2

[0081] This embodiment provides a method for preparing a wafer locking ring, the preparation method comprising the following steps:

[0082] (1) Prepare a cylindrical titanium ingot with a purity of 99.9%, a diameter of 150mm, and a length of 150mm, and carry out forging and stretching at 900°C. Each forging and stretching process is first drawn according to the drawing and forging ratio of 2, and then Upsetting is carried out according to the upsetting forging ratio of 2.5, water cooling is repeated three times, and then the first heat treatment is carried out at 600°C for 150 minutes, and titanium forgings are obtained after air cooling;

[0083] (1') The titanium forging parts described in step (1) are subjected to re-stretching treatment at 750 ° C. Each re-stretching treatment is first drawn according to the elongation forging ratio of 2, and then according to the upsetting forging ratio Upsetting for 2.5, repeated 3 times, water cooling, and then the fourth heat treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com