A heat treatment process for low-density steel and its preparation method

A low-density steel and process technology, which is applied in the heat treatment process of low-density steel and its preparation field, can solve the problems that the performance cannot meet the requirements of some structural parts, and achieve the elimination of residual carbides, increase the degree of compactness, and prevent quality reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

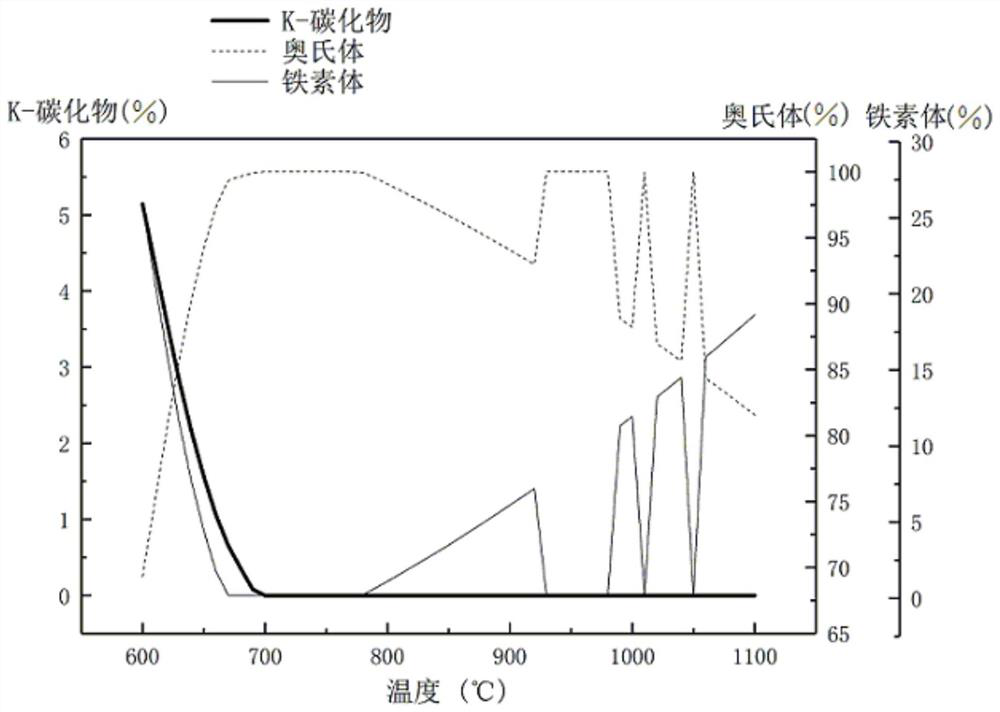

Image

Examples

Embodiment 1

[0060] 1. Smelting

[0061] According to weight percentage, Mn: 30%, Al: 9%, C: 0.9%, Si: 1%, Mo: 0.45%, P: 0.003%, S: 0.003%, and the rest is Fe into the vacuum induction melting furnace. For smelting, argon gas is introduced into the furnace during the smelting process, and additives are added to the molten steel during the smelting process, and the temperature of the molten steel is 1623°C. The addition amount of the additive is 0.01% of the molten steel, and the chemical composition and its mass parts are: rare earth: 10 parts; kaolin: 5 parts; biomass: 2 parts.

[0062] 2. Casting

[0063] Prepare the corresponding mold, lay 2 layers of horse manure paper on the bottom surface of the mold, evenly spread mold slag on the horse manure paper, pour molten steel into the mold for casting, when casting, the mold temperature of the mold is 150 ℃, control the liquid steel The degree of superheat is 25°C. The total amount of mold slag added is 0.2% of the molten steel mass, and...

Embodiment 2

[0076] The basic steps of this example are basically the same as Example 1, the difference is that the following substances are added by weight percentage in the smelting step of this example: Mn: 27%, Al: 10%, C: 1%, Si: 1 %, Mo: 0.5%, P: 0.003%, S: 0.003%, and the rest is Fe.

Embodiment 3

[0078] The basic steps of the present embodiment are basically the same as in the embodiment 1, the difference is that the heat treatment process of the present embodiment is as follows:

[0079] (1) Solution treatment

[0080] Put the hot-rolled low-density steel plate into a vacuum heating furnace at a temperature of 420°C and keep it warm for 35 minutes, then raise the temperature of the heating furnace to 670°C at a rate of 210°C / h and hold it for 35 minutes minutes, then the temperature was raised to 1150°C at a heating rate of 210°C / h, and after 2 hours of heat preservation, the steel plate was taken out and water-cooled to room temperature at a cooling rate of 20°C / s.

[0081] (2) Carbide treatment

[0082] Put the low-density steel obtained in Step 1 into a vacuum heating furnace in a vacuum state, heat to 800° C., keep it warm for 2 hours, take it out and air-cool it to room temperature.

[0083] (3) Aging treatment

[0084] Heat the low-density steel obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com