Advanced mirror gum die steel and manufacturing process thereof

A manufacturing process and die steel technology, applied in the field of high-grade mirror gum die steel and its manufacturing process, can solve the problems of affecting the service life of die steel, insufficient wear resistance, etc., and achieve high compactness, improved oxidation resistance, and structural strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

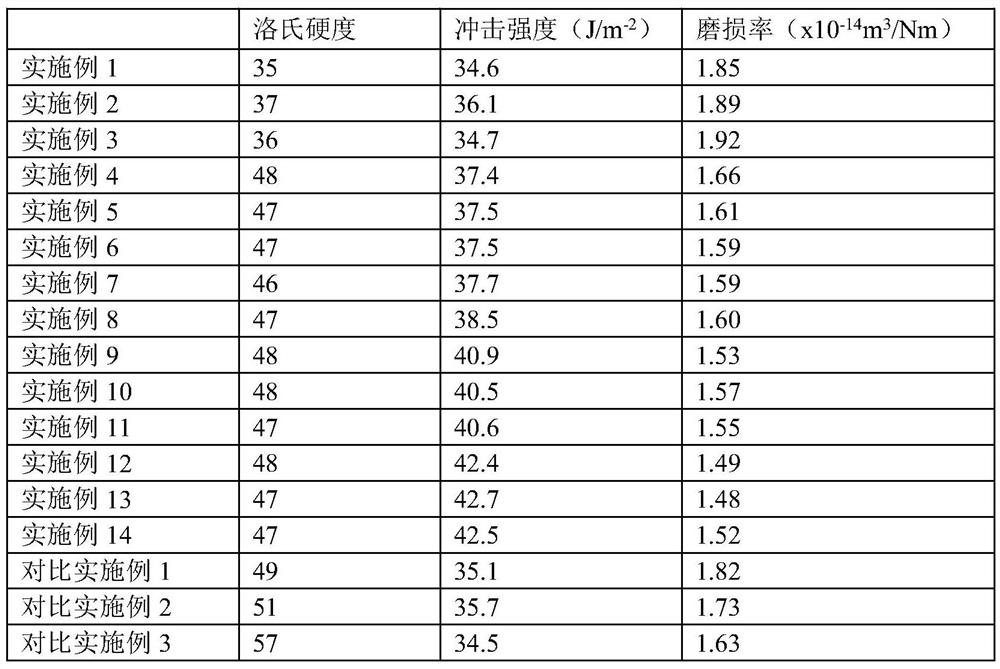

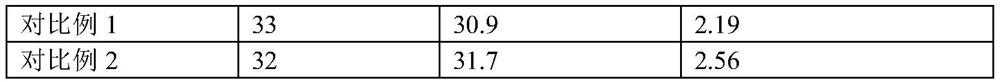

Examples

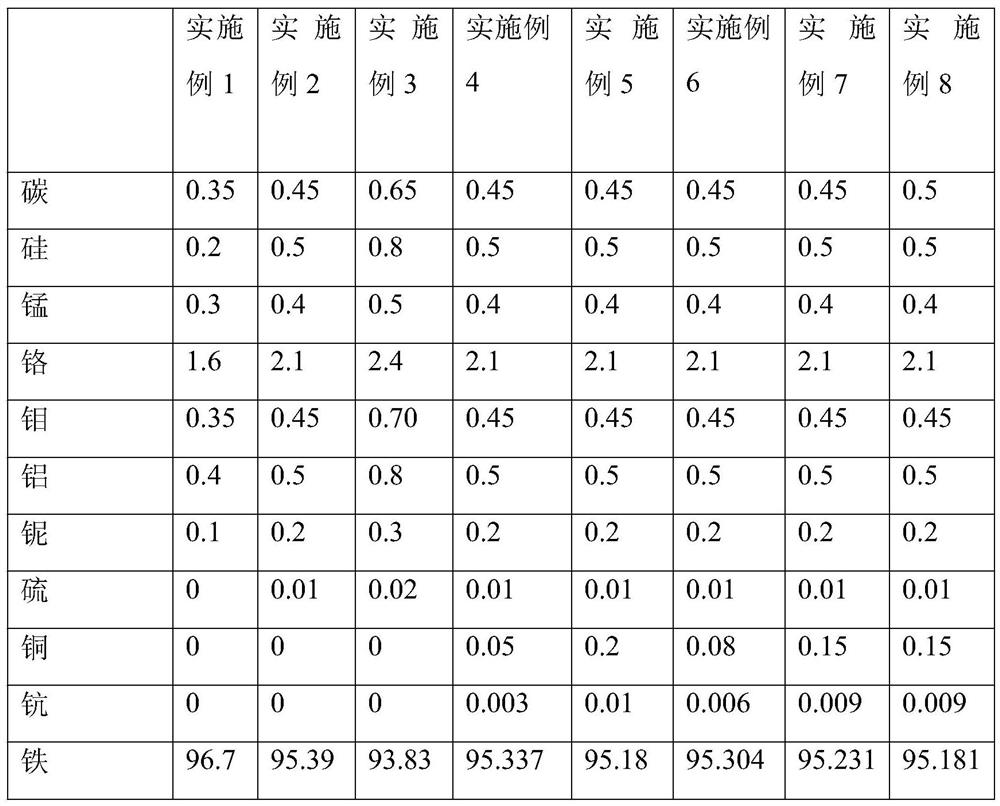

Embodiment 1-3

[0039] Material smelting: batching according to the ratio of the ingredients in Table 1, after smelting in a vacuum induction furnace at 1600°C, pouring to form steel ingots, the pouring temperature is 1450°C;

[0040] High-temperature homogenization treatment: heat the steel ingot to 1180°C, keep it at this temperature for 10 hours, and air-cool to room temperature to obtain a homogenized steel ingot;

[0041] Forging: The steel ingots treated with high temperature homogenization are subjected to Guoxiang forging process. The starting forging temperature is 1130°C, the final forging temperature is 900°C, after forging, the fog is cooled to 470°C, and the temperature in the furnace is 470°C. After holding at ℃ for 3 hours, cool to room temperature with the furnace to obtain forgings;

[0042] Annealing treatment: heat the forging to 880°C, hold for 3 hours, then cool to 610°C with the furnace, and then air cool to room temperature to obtain annealed forging;

[0043] Quenchin...

Embodiment 4-8

[0046] The difference from Example 2 is that in the step of material smelting, the copper powder and scandium powder obtained according to the ratio in Table 1 are added, and after being smelted in a vacuum induction furnace at 1600°C, the steel ingot is casted at a pouring temperature of 1450°C;

[0047] After the quenching and tempering treatment step, a nitriding treatment step is provided before the tempering treatment step.

[0048]Nitriding treatment: Put the quenched and tempered mold into the nitriding furnace, and directly feed ammonia gas to make the atmosphere in the furnace a pure ammonia gas atmosphere. After 3 hours, cool down to room temperature with the furnace to obtain nitriding die steel.

Embodiment 9

[0050] The difference with embodiment 8 is: the quenched and tempered mold is put into the nitriding furnace, and ammonia gas is directly passed into, so that the atmosphere in the furnace is a pure ammonia gas atmosphere, and the air pressure in the nitriding furnace is 1500Pa, and the temperature in the nitriding furnace is raised to After holding at 460°C for 3 hours, then raising the temperature at 0.5°C / min to 485°C and holding for 3 hours, then cooling to room temperature with the furnace to obtain nitriding die steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com