Novel cable sheath pipe embedded with lighting system and installation method

A lighting system and sheathing technology, applied in the field of cable structures, can solve problems such as interference, achieve the effects of sufficient location space, good manufacturing process performance, and reduce construction difficulty and installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

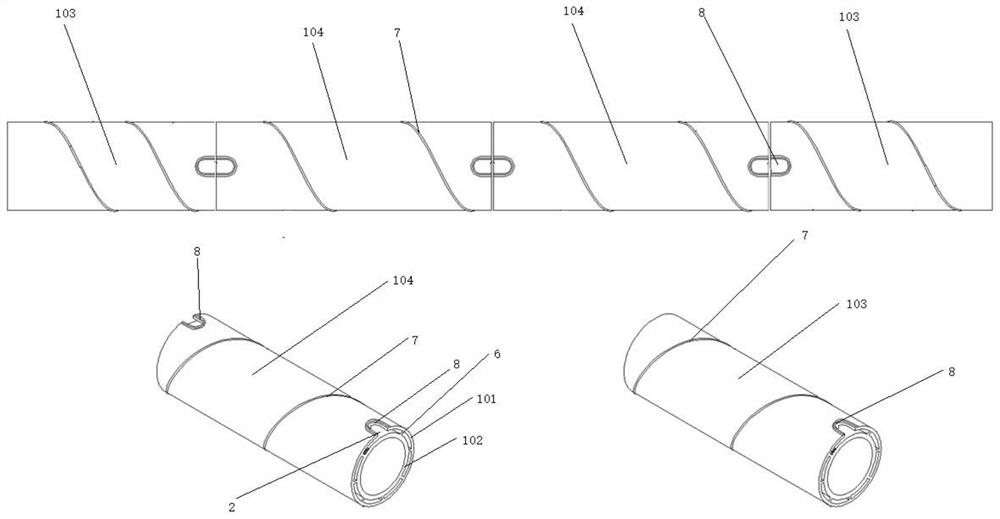

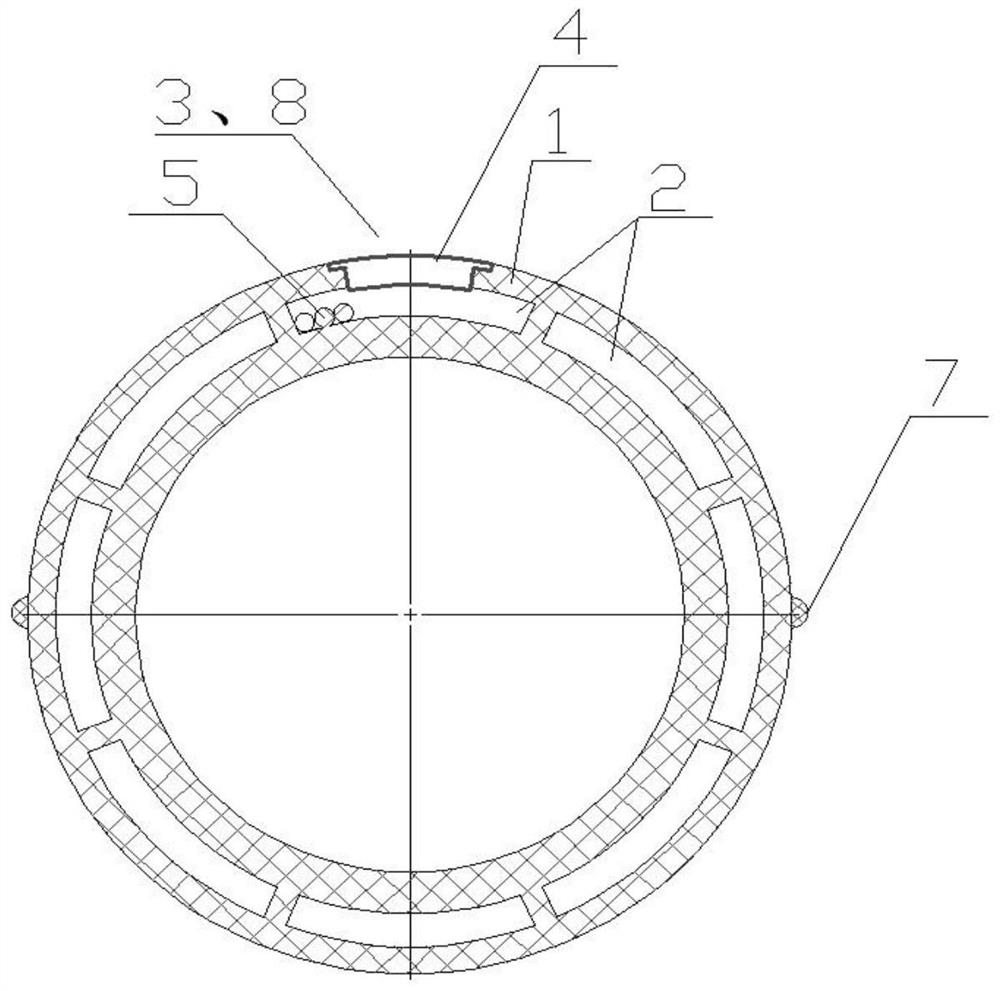

[0034] like figure 1 , Figure 7 As shown, the present invention provides a new type of spiral sheath tube for cables with embedded lighting system. The sheath tube 1 is a double-layer structure sheath tube with an inner layer and an outer layer extruded by a mold. The inner tube layer 101 and the outer layer of the sheath tube 102 are connected by reinforcing ribs 6, and a through hole 2 longitudinally penetrating the sheath tube is provided between the inner layer of the sheath tube 101 and the outer layer 102 of the sheath tube, and the sheath tube includes two The starting and ending end sheath pipe 103 and at least one intermediate section sheathing pipe 104, the middle section sheathing pipe 104 is arranged in series between the two starting and ending end sheathing pipes 103, the starting and ending end sheathing pipe 103 and the middle section sheathing pipe The spliced lamp groove 8 is provided at the abutting end of the sleeve tube 104, the spliced lamp groove 8...

Embodiment 2

[0039] like figure 1 , image 3 and Figure 4 , On the basis of Embodiment 1, the outer surface of the outer layer 101 of the sheath tube is provided with a helix 7 or a pit structure. The outer surface of the outer layer 101 of the sheath tube retains the anti-wind and rain-induced vibration design such as the helix 7 or the pit, which improves the durability of the sheath tube.

Embodiment 3

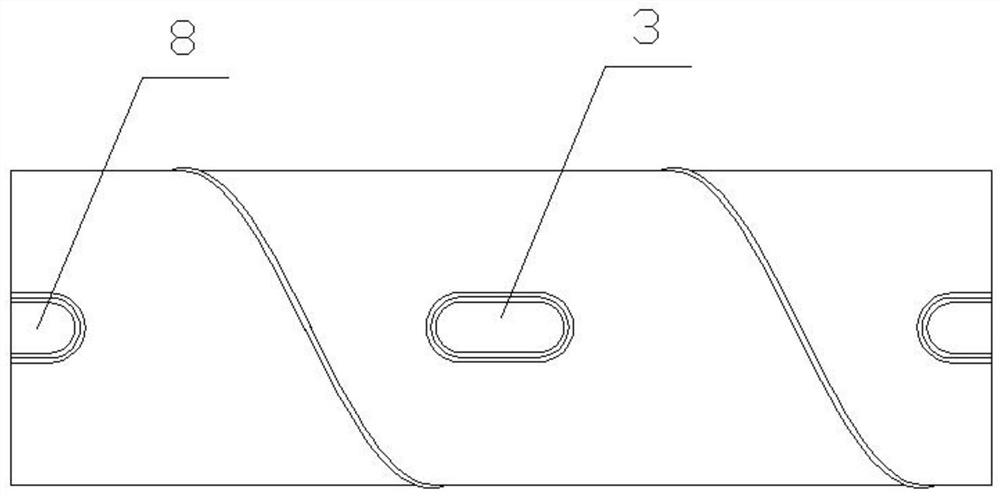

[0041] like figure 2 , Image 6 , On the basis of Embodiment 1, the outer layer of the sheath tube has a lamp groove 3 extending longitudinally, the through hole 2 communicates with the lamp groove 3 , and the lamp groove 3 is used to place the lamp assembly 4 . The lamp groove 3 in this embodiment can be one, and its structure can be the same as the assembled lamp groove 8, or it can be different. When the structure of the lamp groove 3 is different from the assembled lamp groove 8, that is, the sheath tube 1 can At least two or more different lamps are assembled; the lamp groove 3 can also be multiple, and can be combined and processed according to different positions, so that the cable lighting system can achieve more varied lighting effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com