Concrete ground trowelling robot

A robot and concrete technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of increasing labor cost and construction time, difficult to meet the requirements of ground flatness, and high labor intensity, and improve the quality of construction. efficiency, high construction efficiency, and the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

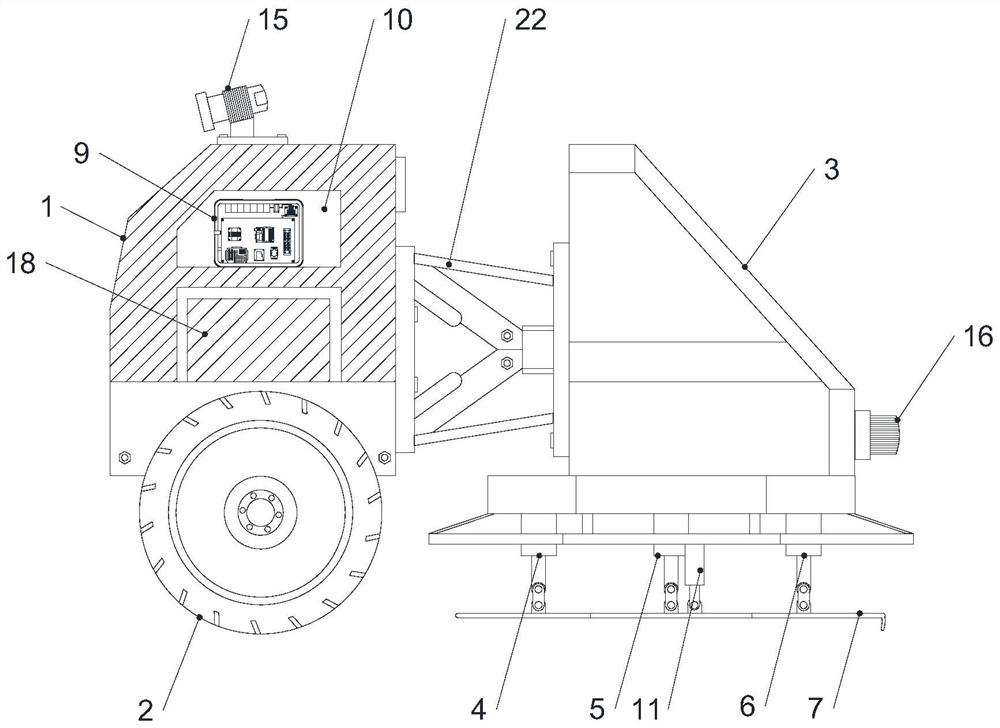

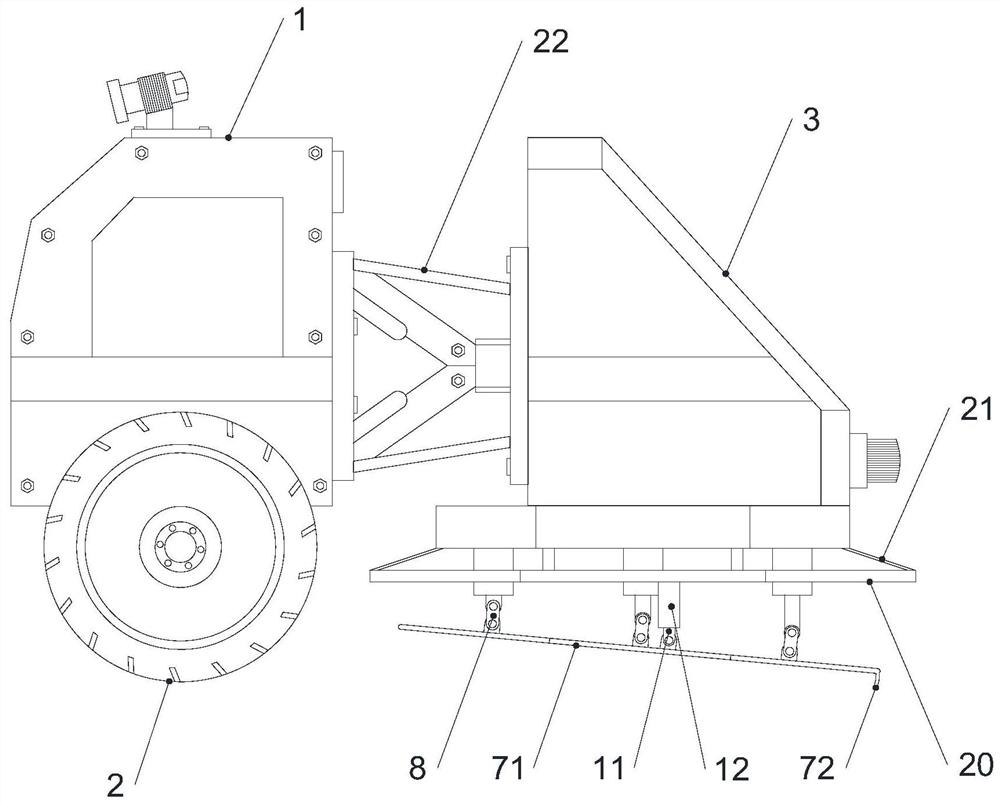

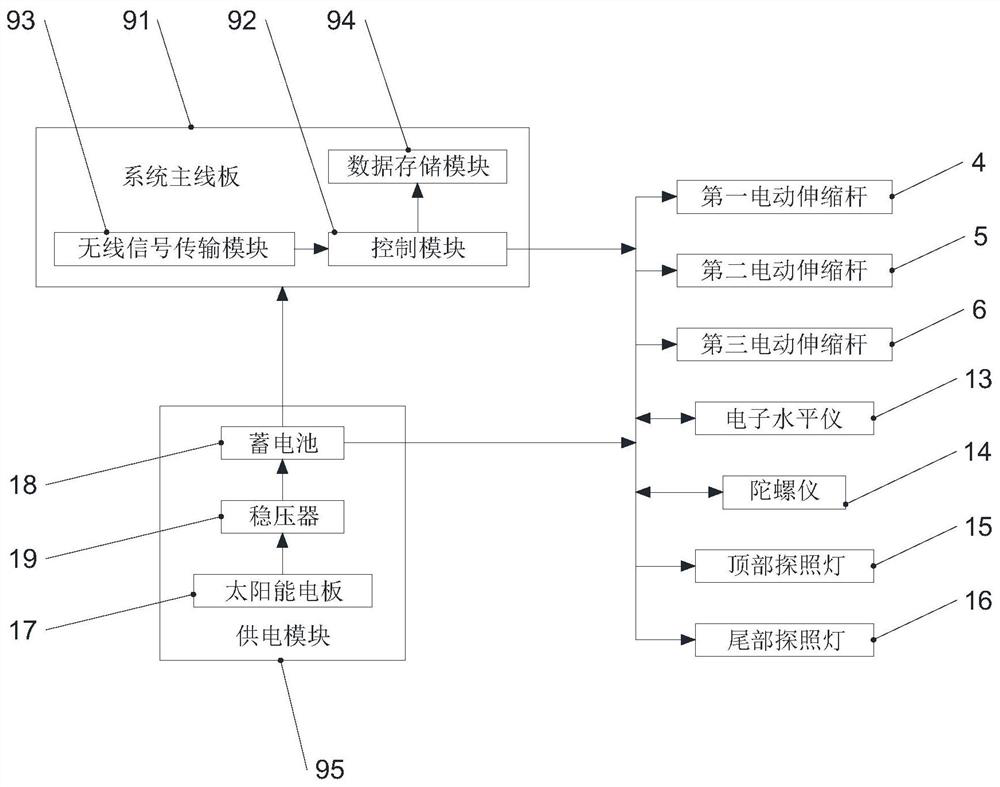

[0025] Example: such as figure 1 and figure 2 As shown, a concrete floor smoothing robot includes a machine head 1, a body 3, a troweling plate 7 with an adjustable inclination angle, and a control box 9 for controlling the operation of the equipment. Drive wheels are arranged on both sides of the machine head 1 2. The drive wheel 2 is in transmission connection with the drive system provided inside the machine head 1 . The fuselage 3 is detachably connected to the nose 1, specifically, a connecting frame 22 is arranged between the nose 1 and the fuselage 3, and the two ends of the connecting frame 22 are respectively connected to the nose 1 and the machine by bolts. Body 3 is fixedly connected. The detachable design between the fuselage 3 and the nose 1 provides convenience for secondary disassembly and assembly on the premise of ensuring the original connection strength, killing two birds with one stone.

[0026] The bottom of the fuselage 3 is fixedly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com