Calculation method of forced excitation hot spot temperature of air-cooled hidden pole synchronous condenser rotor

A technology of hot spot temperature and calculation method, applied in calculation, computer-aided design, complex mathematical operations, etc., can solve problems such as inability to accurately evaluate hot spot temperature, and achieve fast calculation and drawing, easy operation, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the present invention more obvious and comprehensible, preferred embodiments are described in detail below with reference to the accompanying drawings.

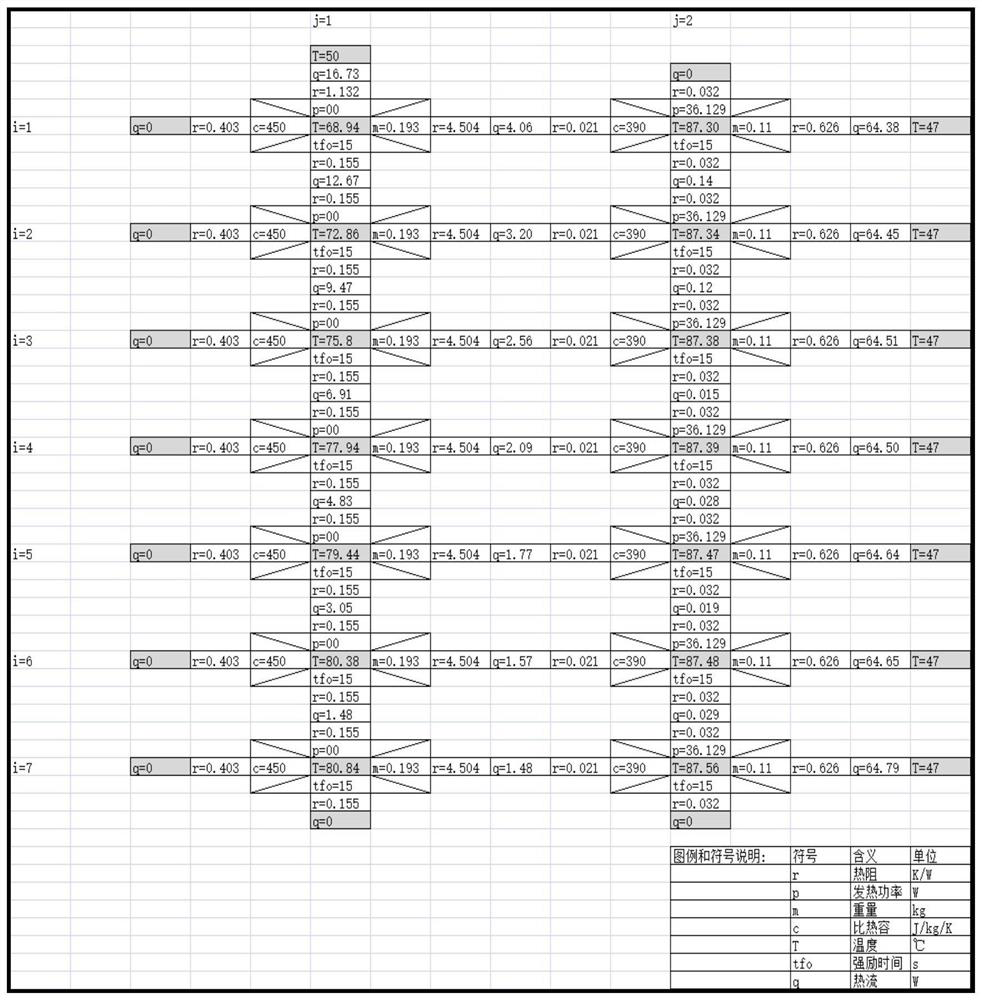

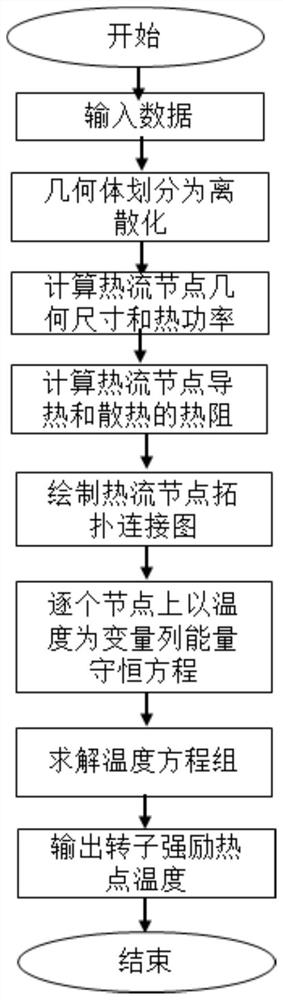

[0049] like image 3 As shown in the present invention, a method for calculating the rotor forced excitation hot spot temperature of an air-cooled non-polar synchronous modulator includes the following steps:

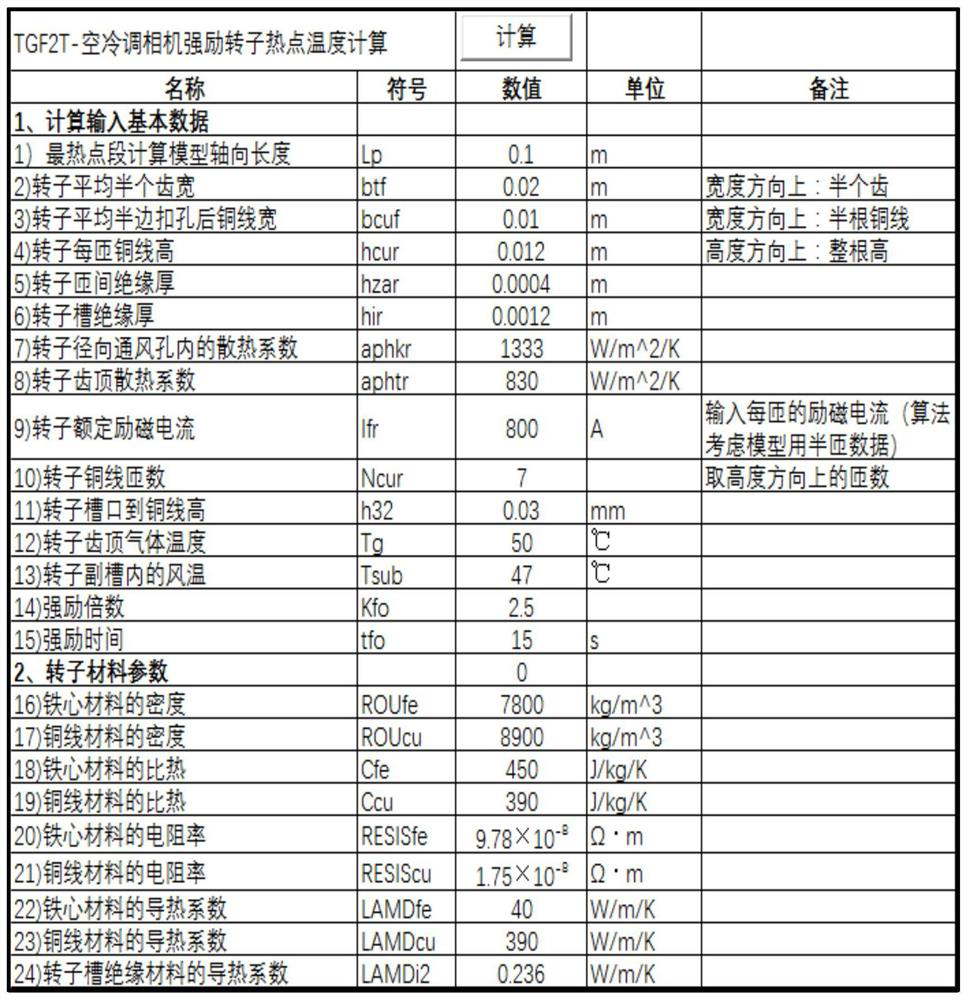

[0050] Step 1: Obtain the parameters and material property parameters of the input calculation model: only need to input 24 parameters, including the axial length L of the calculation model of the hottest point segment p (unit: m), the average half tooth width b of the rotor tf (unit: m), half copper wire width b of rotor cuf (unit: m), the height h of each turn of the rotor copper wire cuf (unit: m), rotor inter-turn insulation thickness h zar (unit: m), rotor slot insulation thickness h ir (unit: m), the heat dissipation coefficient aph in the radial ventilation holes of the rotor kr (Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com