Operating parameter optimization method for complex rectifying tower

A technology of operating parameters and optimization methods, applied in the field of industrial equipment optimization, can solve problems such as reducing solution efficiency and affecting real-time optimization response speed, and achieve the effects of reducing complexity, accelerating convergence speed and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

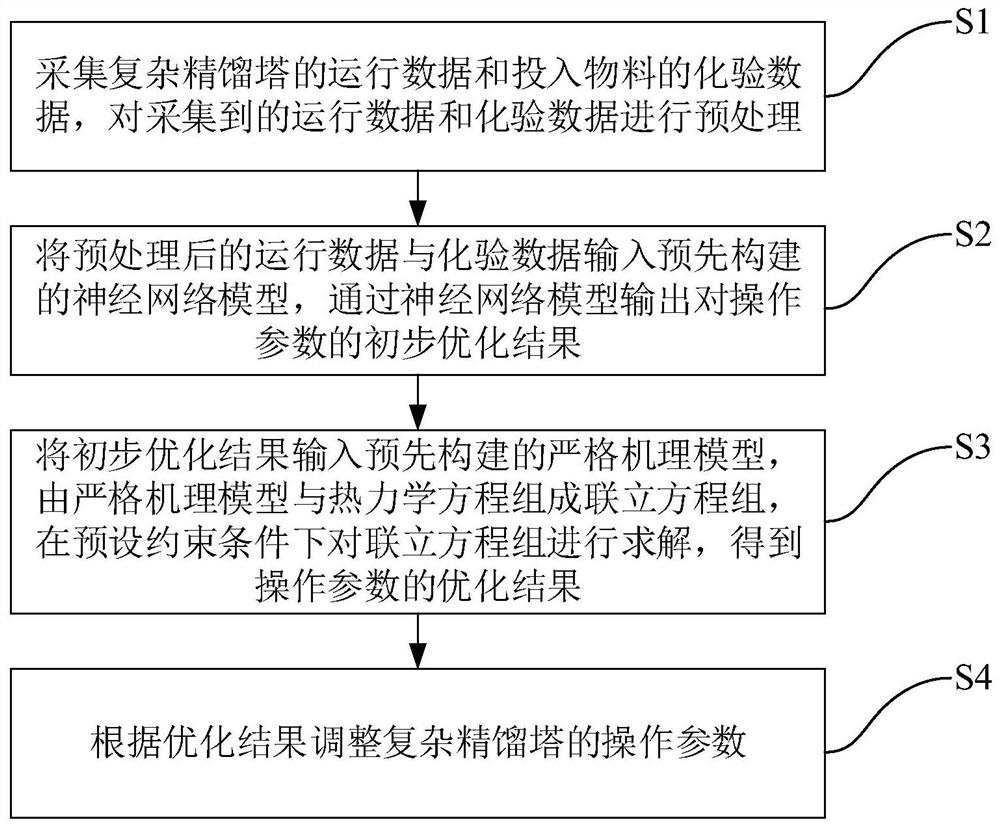

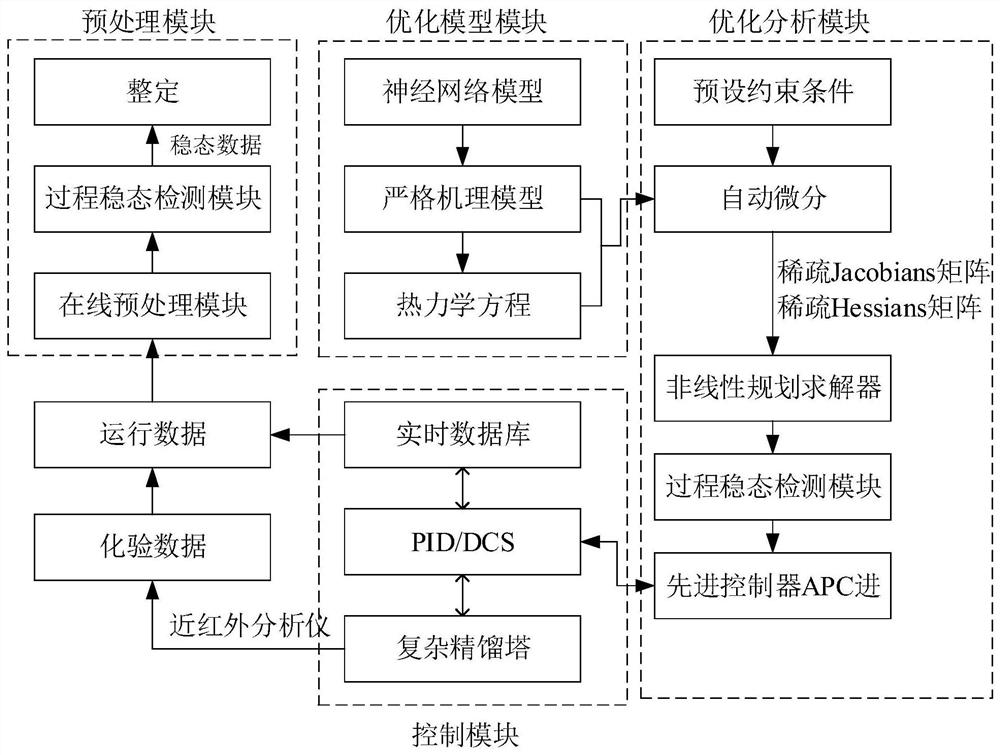

[0036] Such as figure 1 As shown, the present invention proposes a kind of operation parameter optimization method for complex rectification column, comprising:

[0037] S1: Collect the operation data of the complex distillation tower and the test data of the input materials, and preprocess the collected operation data and test data.

[0038] S2: Input the preprocessed operating data and assay data into the pre-built neural network model, and output the preliminary optimization results of the operating parameters through the neural network model.

[0039] S3: Input the preliminary optimization results into the pre-built strict mechanism model, and form a simultaneous equation system from the strict mechanism model and thermodynamic equations, and solve the simultaneous equation system under preset constraints to obtain the optimization results of the operating parameters.

[0040] S4: Adjust the operating parameters of the complex distillation column according to the optimiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com