Automatic finite element modeling method applied to sanitary ware

A modeling method and finite element technology, applied in the field of finite element analysis, can solve problems such as long product development cycle, low efficiency of design analysis, and low level of automatic modeling of sanitary ware, so as to shorten the product development cycle and improve the efficiency of design analysis , the effect of reducing skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

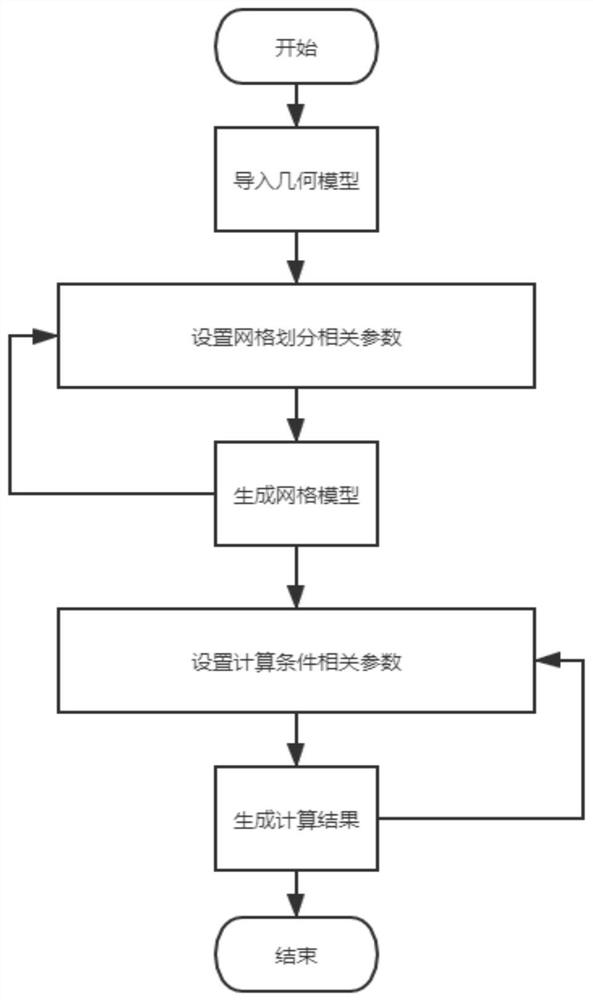

[0020] (1) Sanitary ware model import: select the type of sanitary ware as toilet in the operation interface, and the 3D geometric model modules that need to be imported at this time are: water tank, seat ring, water bag, pipe, and the 3D geometric model of the above modules import separately

[0021] (2) Finite element meshing parameter setting: According to the type of sanitary ware and actual needs, set the meshing parameters for each module of sanitary ware, including: element shape control parameters, element size control parameters

[0022] Since the geometric model of sanitary ware is generally large and the geometric shape is relatively complex, considering factors such as calculation time and accuracy, it is necessary to use a mixture of structured grid and unstructured grid for grid division: for the siphon toilet, it is necessary to The grid unit shape of the module with a relatively regular shape of the toilet is set as a hexahedral mesh, and the shape of the grid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com