Automatic flight method for wind turbine generator blade routing inspection blade area route

A wind turbine, automatic flight technology, applied in non-electric variable control, vehicle position/route/altitude control, computer parts and other directions, can solve the problem that the wind turbine cannot be inspected, the operator's remote control is difficult, and the inspection results are inaccurate. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

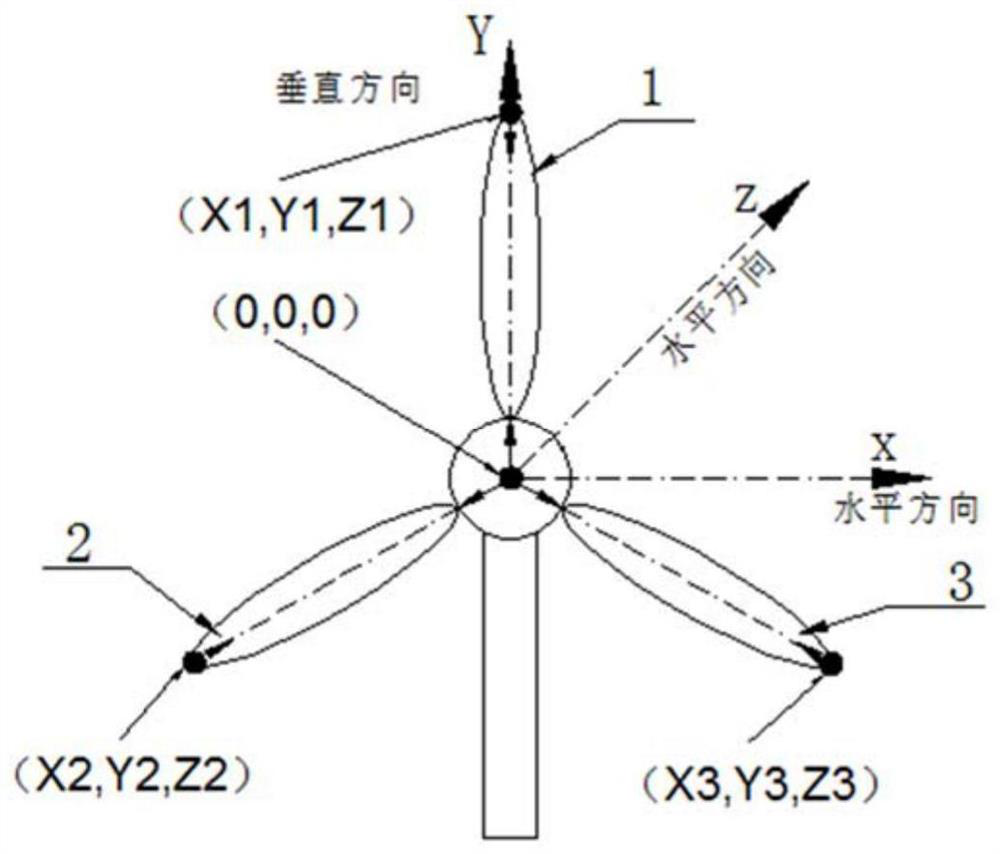

[0042] Such as figure 1 As shown, a method for automatic flight of a wind turbine blade inspection blade area route in the present invention includes the following steps:

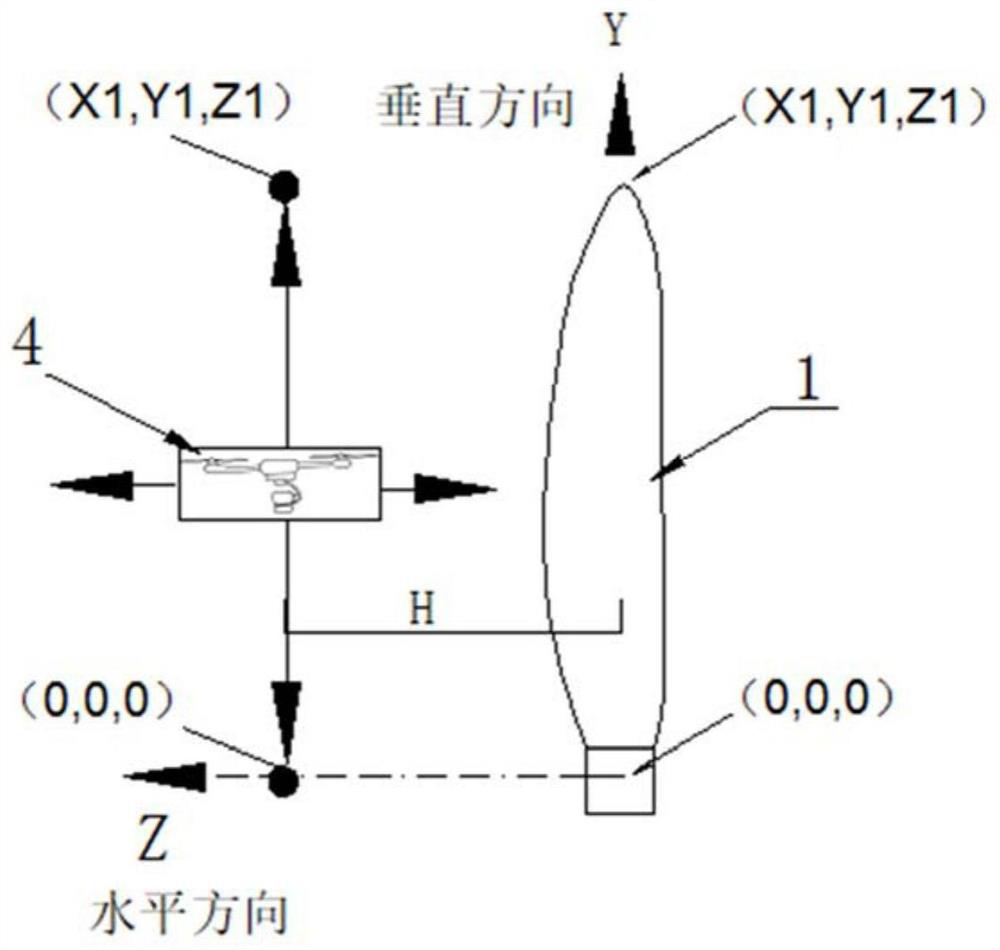

[0043] The first step is to establish the UAV 4 space positioning coordinate system:

[0044] Such as figure 1 and figure 2 As shown, stop the wind turbine and put the blades in the figure 1 In the inverted Y position shown, the center of the hub of the wind turbine is artificially set as the origin of the coordinate system, and a three-dimensional coordinate system is established, in which the horizontal direction is the X axis and the Z axis, and the vertical direction of the horizontal plane is the Y axis. Coordinates are in cm.

[0045] The second step is to set the inspection path point:

[0046] Specifically, such as figure 1 As shown, set the hub center of the wind turbine as the origin of the coordinate system, and its coordinates are (0, 0, 0), and set the first blade 1, the second blade 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com