Asymmetric magnetic barrier permanent magnet assisted reluctance synchronous linear motor

A synchronous linear motor, asymmetric technology, applied in the direction of magnetic circuit, electromechanical device, electrical components, etc., can solve the problem of permanent magnet assisted reluctance synchronous linear thrust fluctuations and other problems, so that the average thrust will not decrease, and the volume and loss will increase Large, the effect of suppressing thrust fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

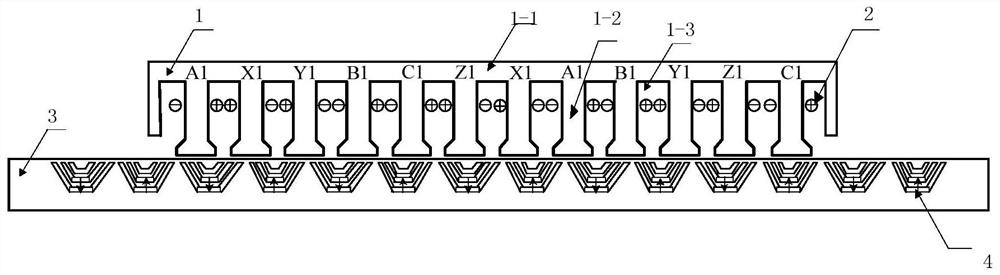

[0031] Such as figure 1 , 2 As shown, this embodiment is a unilateral asymmetric magnetic barrier permanent magnet assisted reluctance synchronous linear motor, which includes a primary assembly and a secondary assembly. The primary assembly consists of the primary core 1 and the armature winding 2 . The primary core 1 is slotted to form a primary core yoke 1-1, primary core teeth 1-2 and slots 1-3. In this example, the slots 1-3 include eleven middle slots 1-3-1, two end slots 1-3-2, and the two end slots are half slots, thirteen slots in total. The armature winding 2 is arranged in the slot 1-3, and the winding adopts a concentrated winding structure. The secondary assembly is mainly composed of the secondary iron core 3 and the permanent magnet 4. There is an air gap structure between the primary assembly and the secondary assembly.

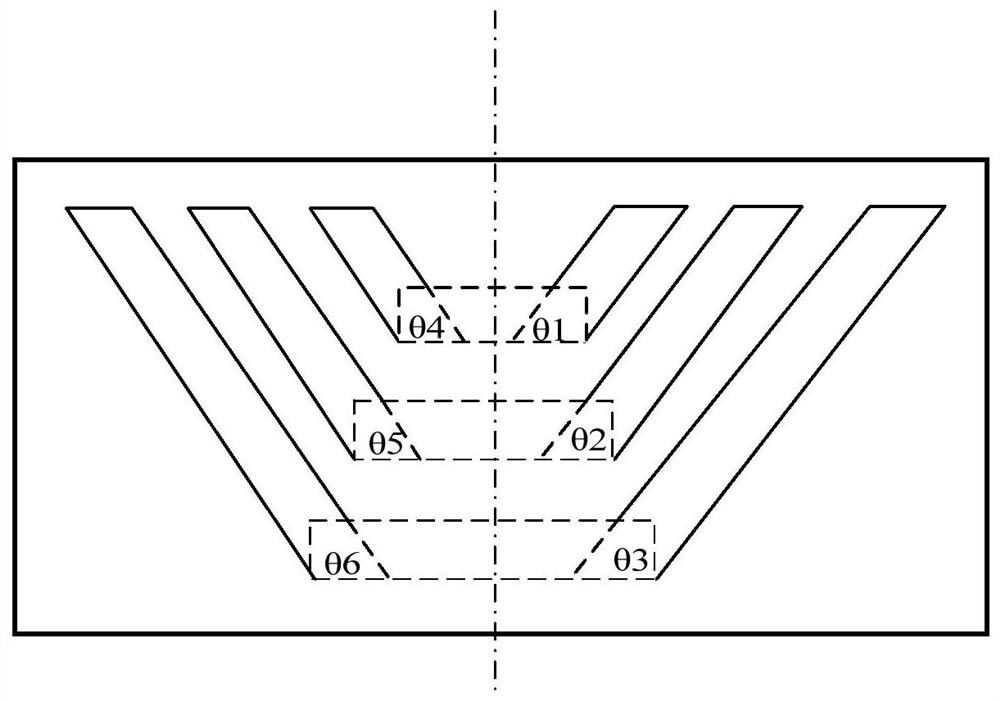

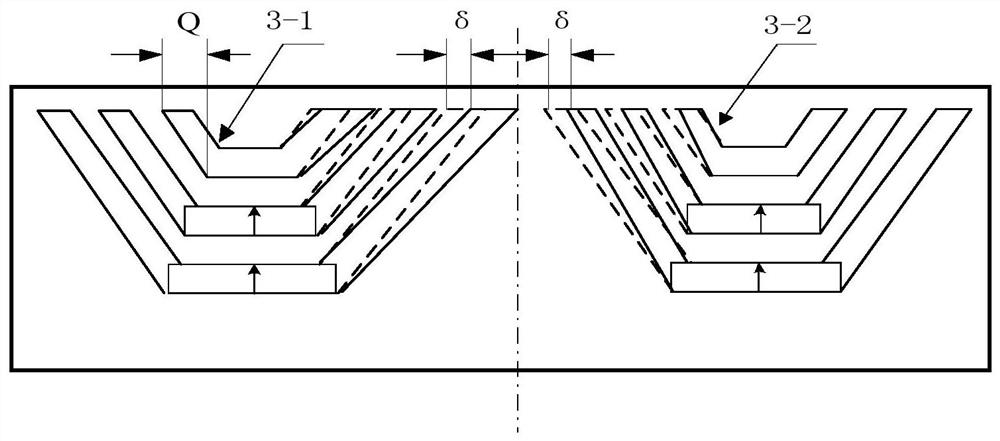

[0032] Two sets of trapezoidal magnetic barriers are arranged respectively under each pair of pole pitches of the secondary core 3 . In ...

Embodiment 2

[0038] Such as Figure 4 As shown, the difference between the present embodiment and the first embodiment is that a double-sided dislocation magnetic barrier structure is adopted, and the double-sided asymmetric magnetic barrier permanent magnet assisted reluctance synchronous linear motor has a staggered displacement of the adjacent magnetic barriers on the upper and lower sides by τ / 2( τ is the secondary pole distance of the motor). The phase winding adopts fractional slot concentrated winding, the upper layer coil arrangement is: A1-X1-Y1-B1-C1-Z1-X1-A1-B1-Y1-Z1-C1; the lower layer coil arrangement is: A2-X2-Y2-B2- C2-Z2-X2-A2-B2-Y2-Z2-C2. The phase difference between the upper and lower coil currents is 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com