Sea cucumber drying method based on near-infrared pretreatment, treatment device and application

A drying method and near-infrared technology, which is applied in the fields of application, food drying, and drying and preservation of meat/fish, etc., can solve the problems of less research on the application of medium and short-wave infrared, and achieve the effect of reducing energy consumption and shortening the required time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 A sea cucumber energy-saving freeze-drying method combined with near-infrared pretreatment

[0046] 1.1 kg of frozen fresh sea cucumbers (6 pieces) were scalded with boiling water for 5 minutes after the viscera were removed to obtain 220 g of blanched sea cucumber skins. Put these sea cucumber skins whole on the sample pan of the near-infrared drying oven. Turn on the near-infrared lamp, the energy density is 5000W / m 2 . After processing for 5 minutes, take out the quick-frozen, and then use a freeze dryer to continue dehydration. After drying, the mass of sea cucumbers is 52g; the increase in the heat flux density of far-infrared rays can shorten the drying time; Freeze drying time, the total drying time is shortened by 12%.

Embodiment 2

[0047] Example 2 A sea cucumber energy-saving freeze-drying method combined with near-infrared pretreatment

[0048] 2.1 kg of frozen fresh sea cucumbers (12) were scalded with boiling water for 5 minutes after removing internal organs, to obtain 430 g of blanched sea cucumber skins. Put these sea cucumber skins whole on the sample pan of the near-infrared drying oven. Turn on the near-infrared lamp, the energy density is 5000W / m 2 . After processing for 10 minutes, take out the quick-frozen, and then use a freeze dryer to continue dehydration. After drying, the sea cucumber has a mass of 90g; the increase in the heat flux density of far-infrared rays can shorten the drying time; far-infrared pretreatment is conducive to improving drying speed and efficiency, shortening the sea cucumber Freeze drying time, the total drying time is shortened by 10%.

Embodiment 3

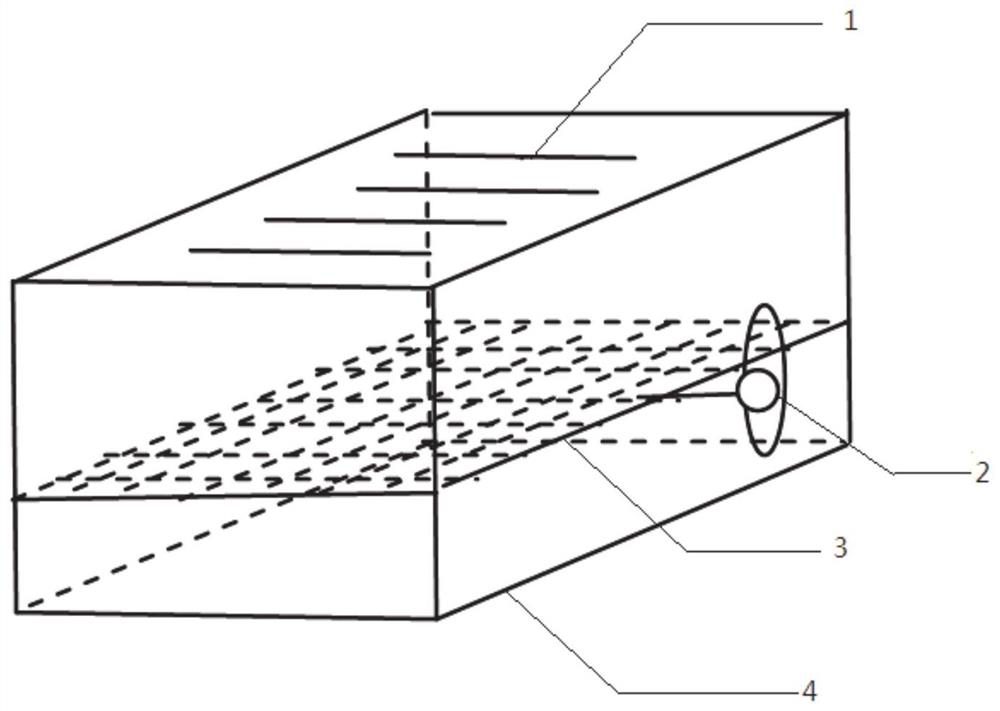

[0050] In this embodiment, a kind of near-infrared processing equipment is provided, and the said near-infrared processing equipment has a drying room, and its structure is as attached figure 1 shown. The drying chamber is a square shell, and four near-infrared lamp heating tubes 1 are distributed above the drying chamber. The near-infrared lamp heating tubes 1 are connected in series in pairs and controlled by individual switches, thereby achieving 5000W / m 2 and 10000W / m 2 Two levels of infrared irradiation density switching.

[0051] A sample tray 3 is arranged in the middle of the drying chamber. The sample tray is a mesh-shaped flat plate. During the pretreatment process, sea cucumbers will continuously ooze liquid. The sample tray 3 with a mesh structure can facilitate the rapid removal of liquid. The bottom of the drying chamber also has a collection tray 4 for receiving the moisture produced by sea cucumbers during the drying process. Quickly removing the exudate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com