Ultrafine powder grinding preparation device and method

An ultra-fine powder and preparation device technology, applied in grain processing and other directions, can solve the problems of difficulty in preparing ultra-fine powder, long grinding time, low grinding efficiency, etc., and achieve high screening efficiency, continuous preparation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

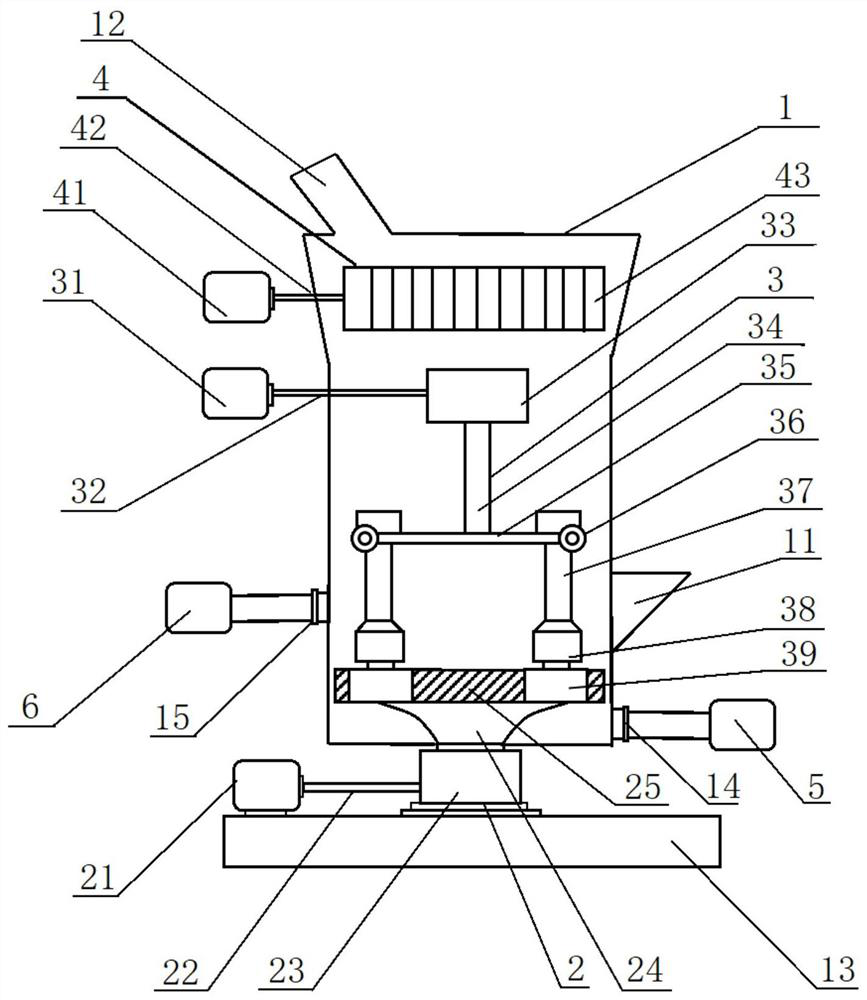

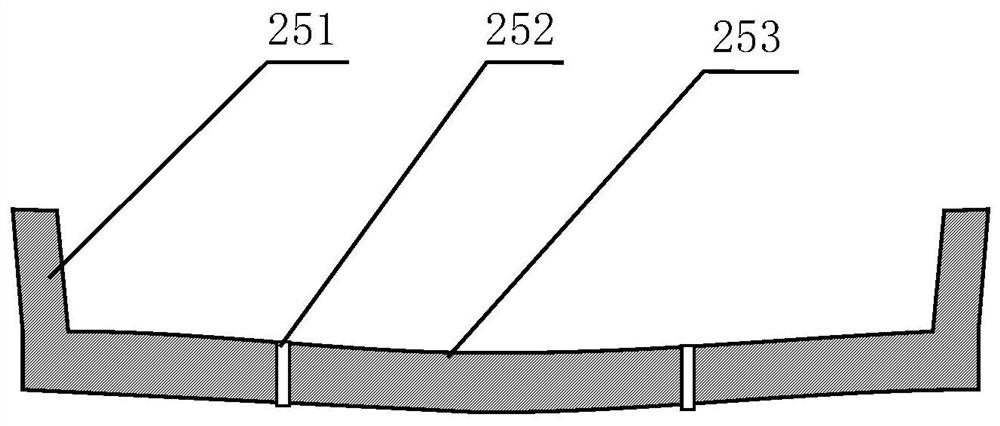

[0028] Such as Figure 1-2 As shown, an ultrafine powder grinding preparation device includes a housing 1 , a first grinding mechanism 2 , a second grinding mechanism 3 , a screening device 4 and a first fan 5 . The casing 1 is a hollow structure, and the casing 1 is provided with an inlet 11 and an outlet 12 , the inlet 11 is arranged on the side of the casing 1 , and the outlet 12 is arranged on the top of the casing 1 . The first grinding mechanism 2 is located at the bottom of the housing 1. The first grinding mechanism 2 includes a first driving device 21, a first speed reducer 23, a first main shaft 24 and a grinding disc 25. The first driving device 21 passes through the first shaft coupling. 22 is connected with the first reducer 23, the output end of the first reducer 23 is connected with one end of the first main shaft 24, and the other end of the first main shaft 24 is connected with the grinding disc 25. The grinding disc 25 is arranged in the casing 1, and the gr...

Embodiment 2

[0043] The difference from Example 1 is that a method for preparing magnesium hydroxide powder comprises the following steps:

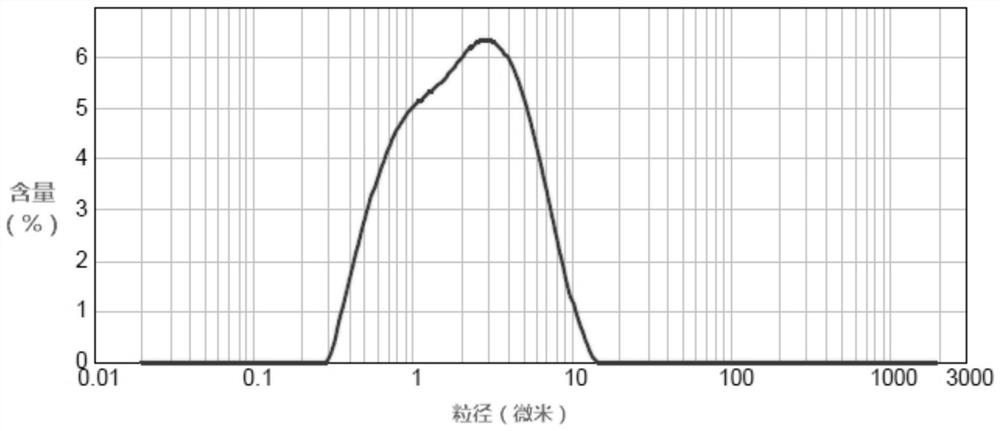

[0044] S1. Mix light-burned magnesium oxide powder with water to form a slurry with a solid mass fraction of 30% to 70%. The slurry is added to the base 252 of the grinding disc 25 through the feed port 11, and the first driving device 21 and the second driving device 31 are turned on at the same time, and the first driving device 21 drives the first coupling 22 and the first reducer 23 to work , and the first reducer 23 drives the first main shaft 24 and the grinding disc 25 to rotate clockwise at a speed of 200 rpm, and the material flows into the inner peripheral grinding ring 251 under the action of centrifugal force; the second driving device 31 drives the second shaft coupling 32, the second reducer 33 work, and the second reducer 33 drives the grinding roller 39 to rotate counterclockwise, and the rotating speed is 200 rpm. At this time, the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com