High speed frictional wear experiment auxiliary device allocated on a lathe

A friction and wear test and auxiliary device technology, applied in the direction of testing wear resistance, etc., to achieve the effects of good adaptability, simple sample requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

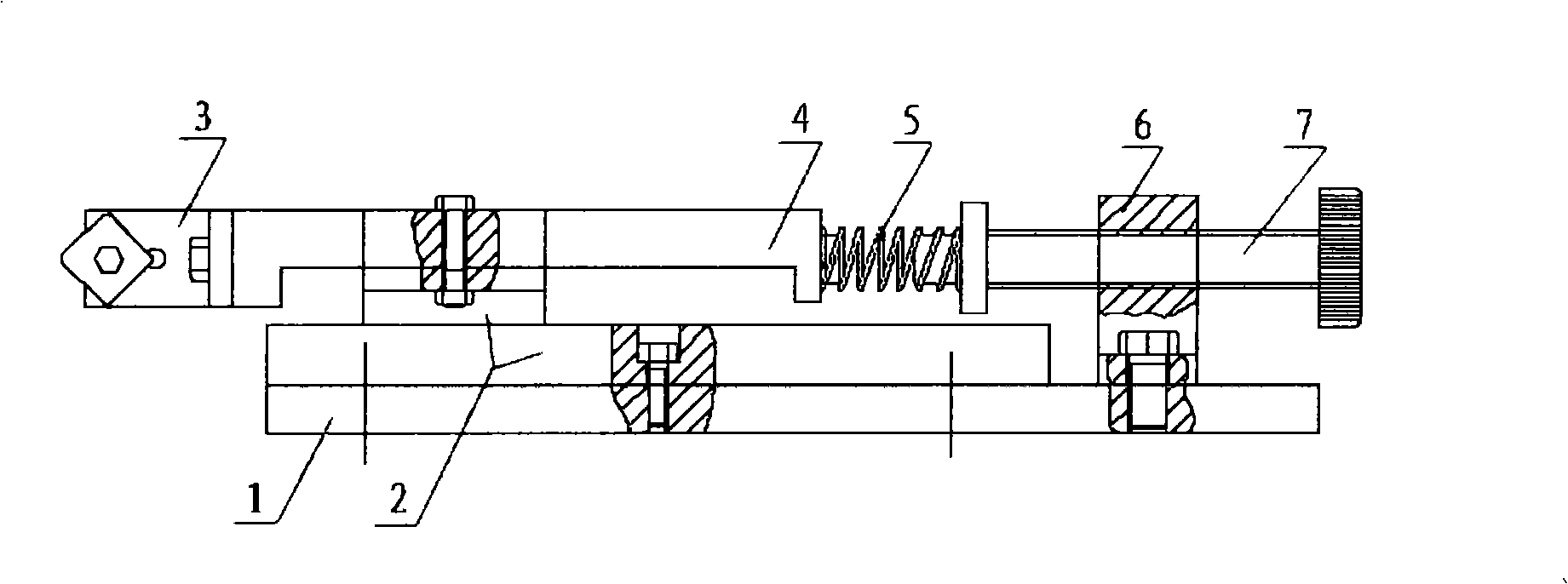

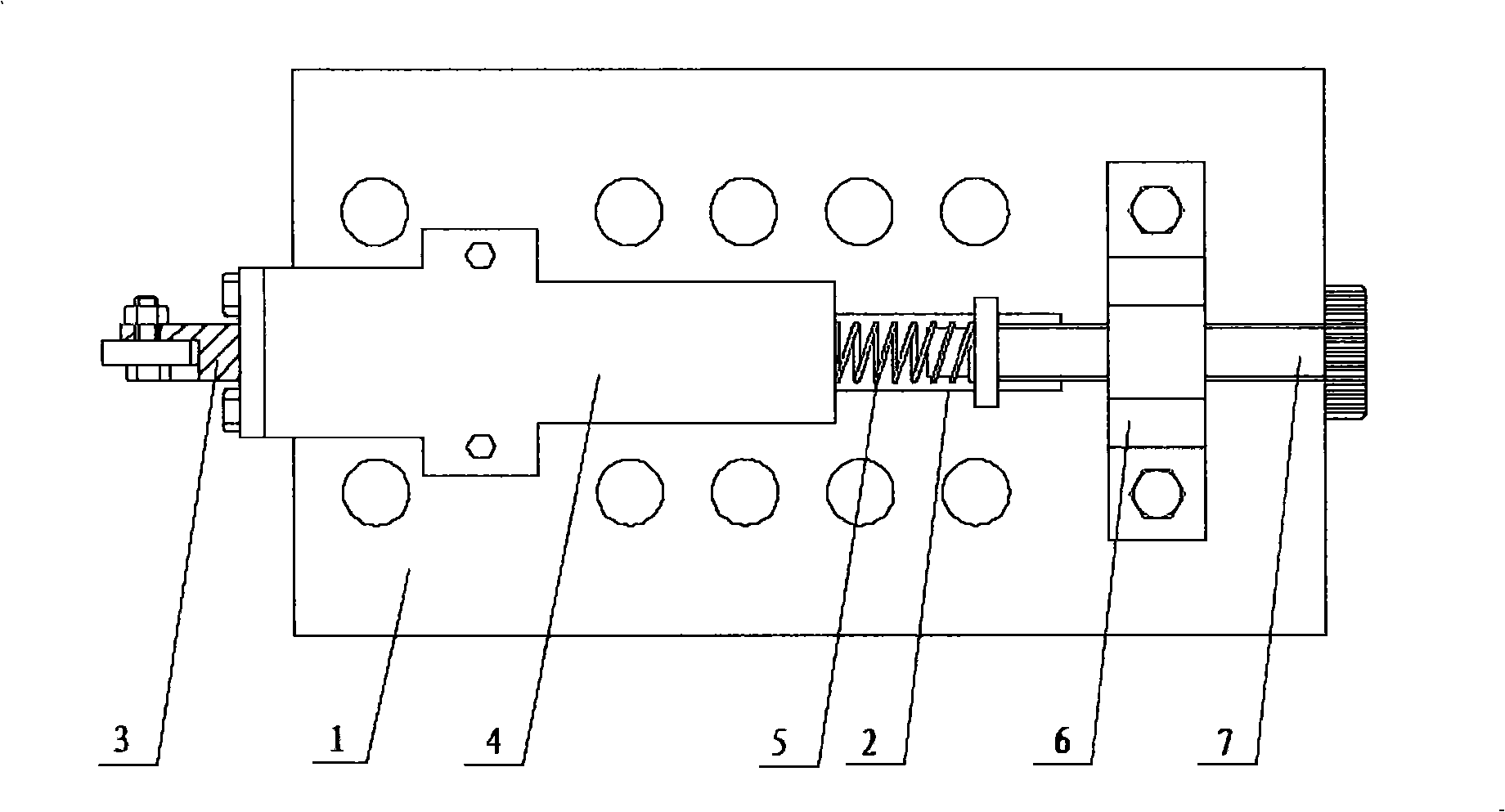

[0013] The present invention is realized through the following measures: the device includes a bottom plate 1, a sliding guide rail pair 2, a chuck 3, and a loading mechanism. The loading mechanism includes an auxiliary body 4 , a spring 5 , a bolt seat 6 and a loading bolt 7 . The uses and features are:

[0014] Base plate 1 is the base of the device, and there are bolt connection holes above, which can be fixed on the three-way dynamometer with bolts.

[0015] The sliding guide rail pair 2 is fixed on the bottom plate and is used for accommodating the auxiliary body 4. Since the friction force of the guide rail pair is negligible, the load can be transferred more accurately.

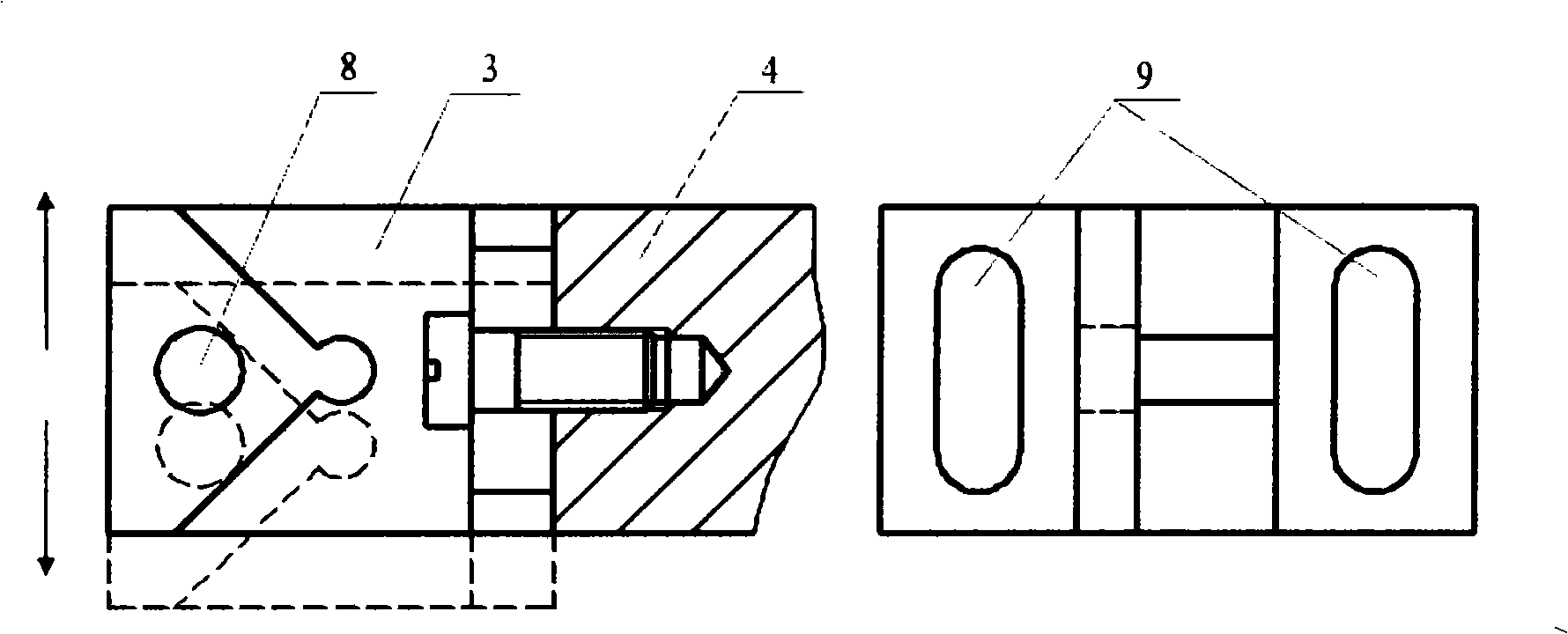

[0016] The chuck 3 is installed on the auxiliary body 4 to hold the sample I12; the shape of the chuck can be designed according to the shape of the sample I12 required for the test. The collet 3 is provided with a positioning groove 9, and the connection position with the auxiliary body 4 can be adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com