Plate side wall grinding device

A technology for plates and grinding blocks, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc. It can solve the problems of easily scratching workers' hands, cumbersome grinding methods, and affecting later use, so as to maintain stability Sexuality, improving convenience, and avoiding labor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

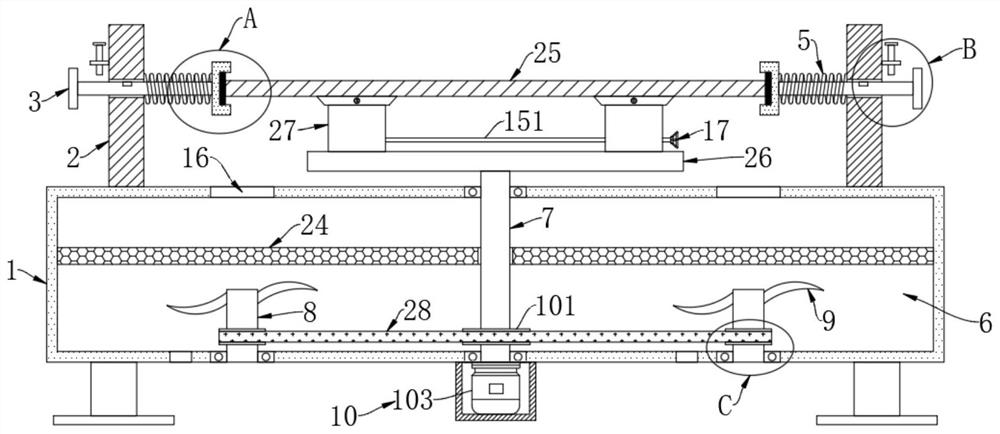

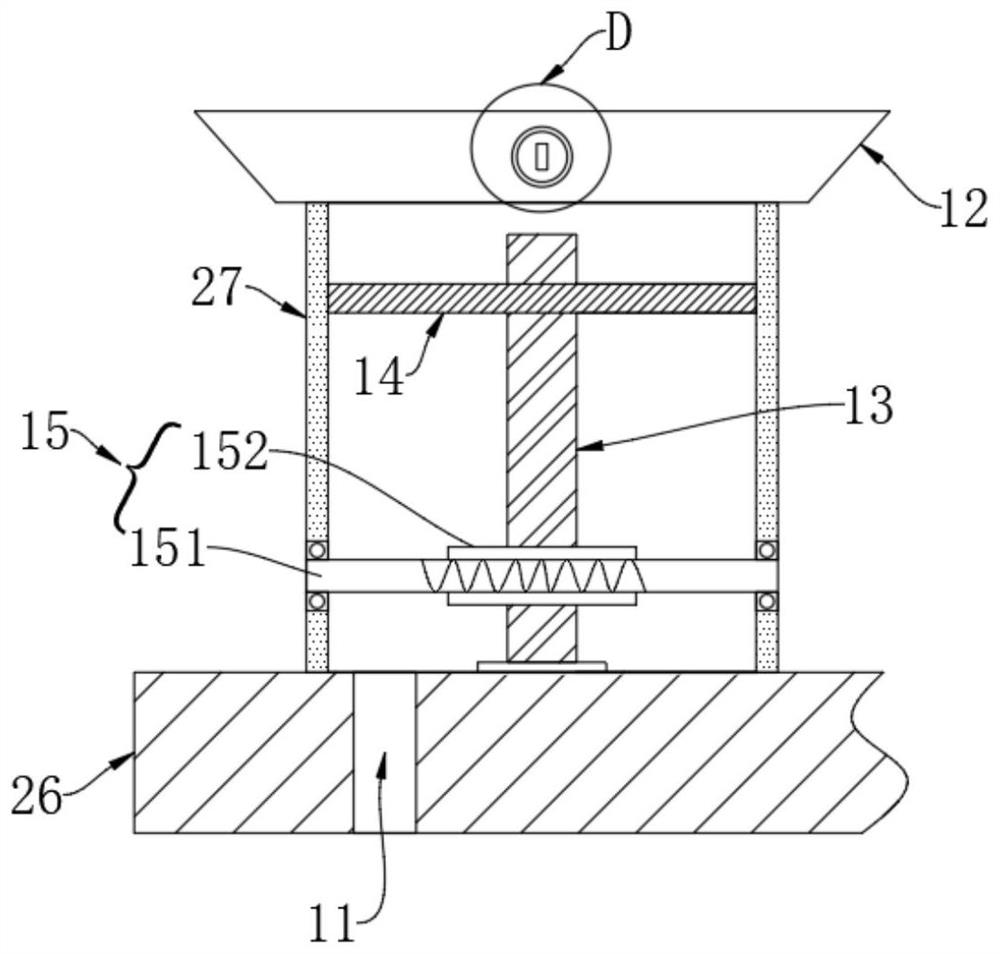

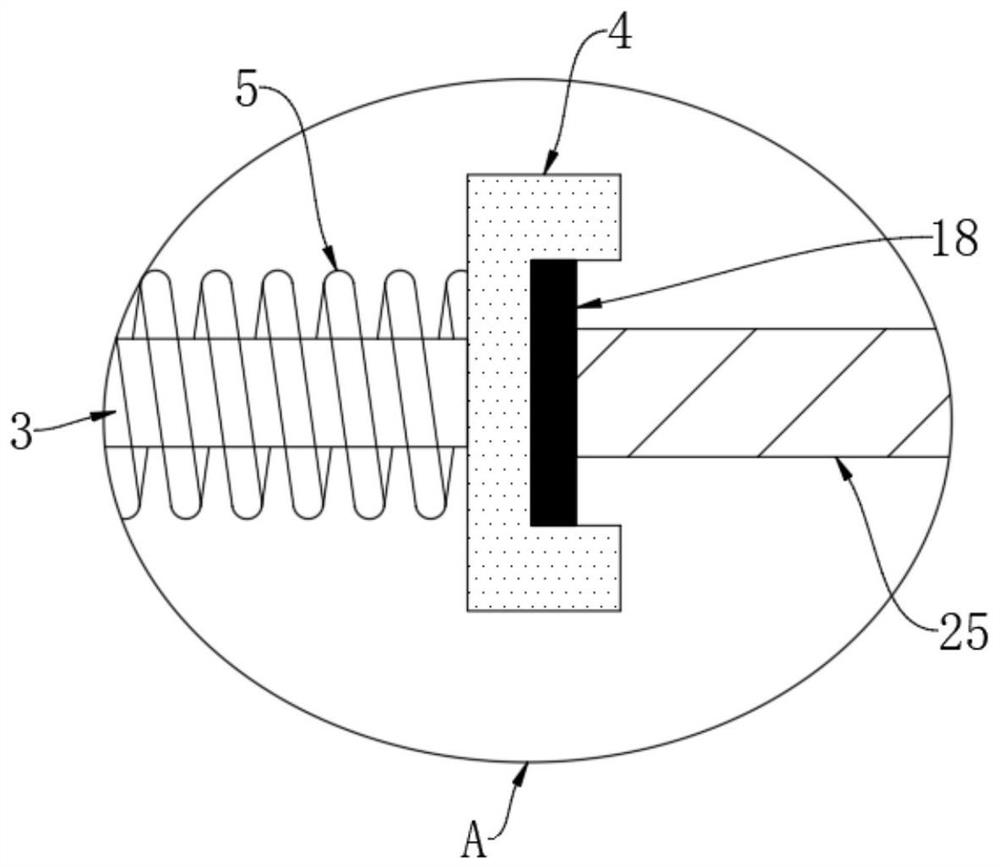

[0033] Such as Figure 1-6 As shown, a plate side wall grinding device includes a workbench 1, two support plates 2 are fixedly connected to the workbench 1, a tie rod 3 is slidably connected to the support plate 2, and a polishing block 4 is fixedly connected to the tie rod 3, The grinding block 4 is designed with a concave structure, and the grinding block 4 is bonded with a grinding paper 18. By designing the grinding block 4 in a concave shape, it can better fit the side wall of the circular plate 25, so that the circular plate 25 can rotate During the process, it can be fully polished by the grinding paper 18, which greatly improves the grinding effect of the device.

[0034] A return spring 5 is fixedly connected between the grinding block 4 and the support plate 2, and the pull rod 3 is sleeved in the return spring 5. Through the return spring 5 provided, the pull rod 3 can be stretched within a certain range, and then the pull rod 3 can be stretched. The grinding bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com