Water and ink co-feeding device of commercial printing machine

A printing press and ink technology, applied in printing presses, rotary printing presses, offset rotary printing presses, etc., can solve problems such as the inability to accurately control the water supply and affect the printing quality, achieve bright colors, improve the quality of finished products, and reduce effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

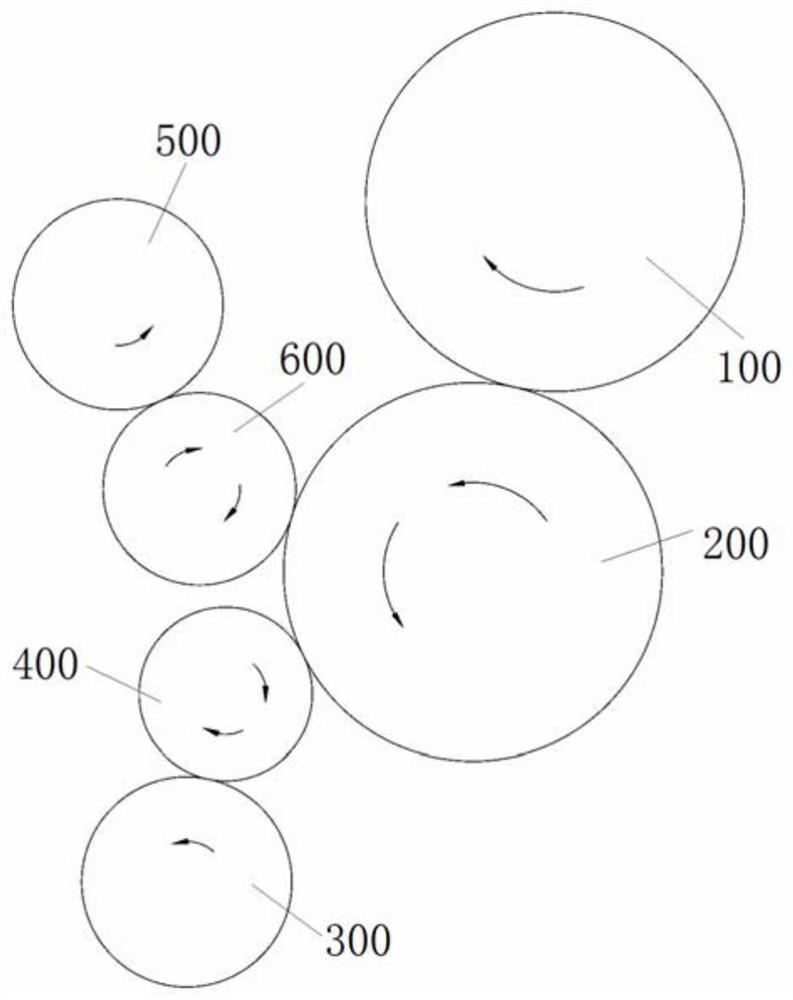

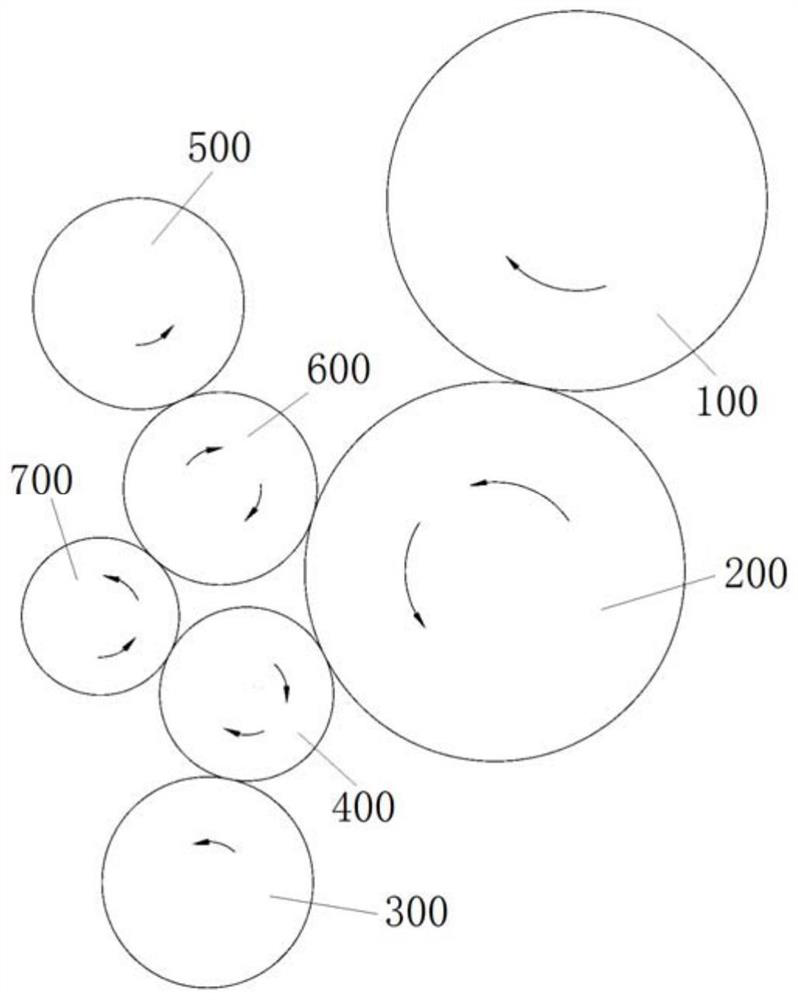

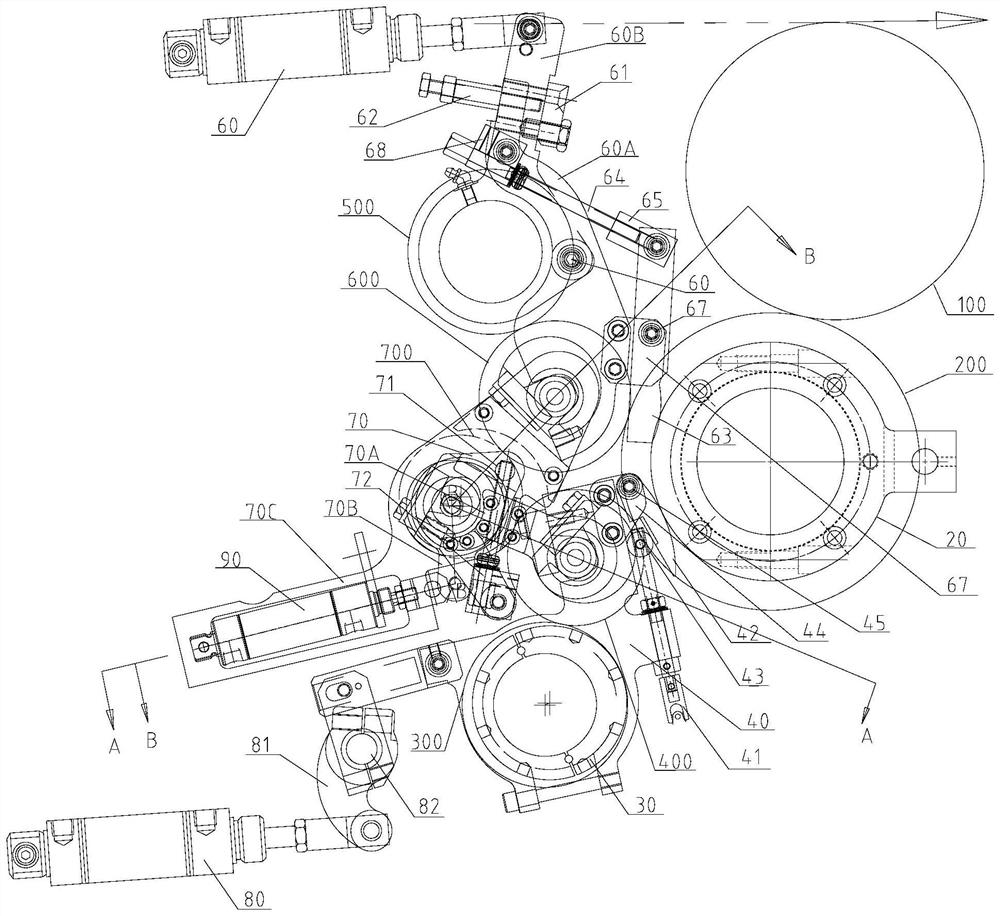

[0037] see Figure 2 to Figure 9 , the water and ink of the commercial printing machine of the present invention co-loads the device, comprises the rubber cylinder 100, the printing plate cylinder 200, the string ink roller 300, the string water roller 500 that straddle between the two side wallboards of the printing press by the bearing seat, also Including the ink form roller 400 matched with the ink roller 300, the pressure adjustment mechanism between the ink form roller and the ink roller, the clutch mechanism between the ink form roller and the plate cylinder, the pressure adjustment mechanism between the ink form roller and the plate cylinder, and the ink form roller 500. The damping roller 600, the damping roller and the stringing roller pressure adjustment mechanism, the damping roller and the printing plate cylinder clutch mechanism, the damping roller and the print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com