Packaging lining plate

A liner and packaging technology, which is applied in the field of packaging liners, can solve problems such as sharp corners, product defects, and breakage of card slot tabs, to ensure safety and effectiveness, short disassembly strokes, and smooth and simple operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

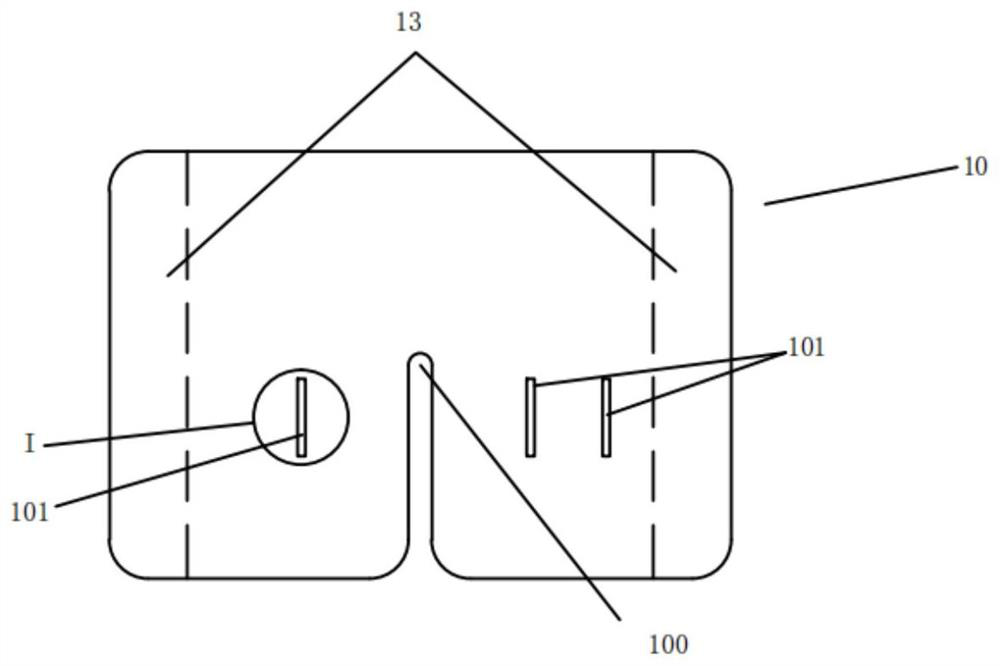

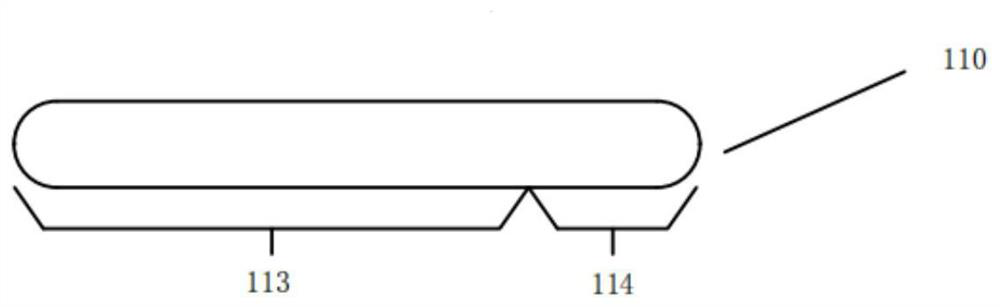

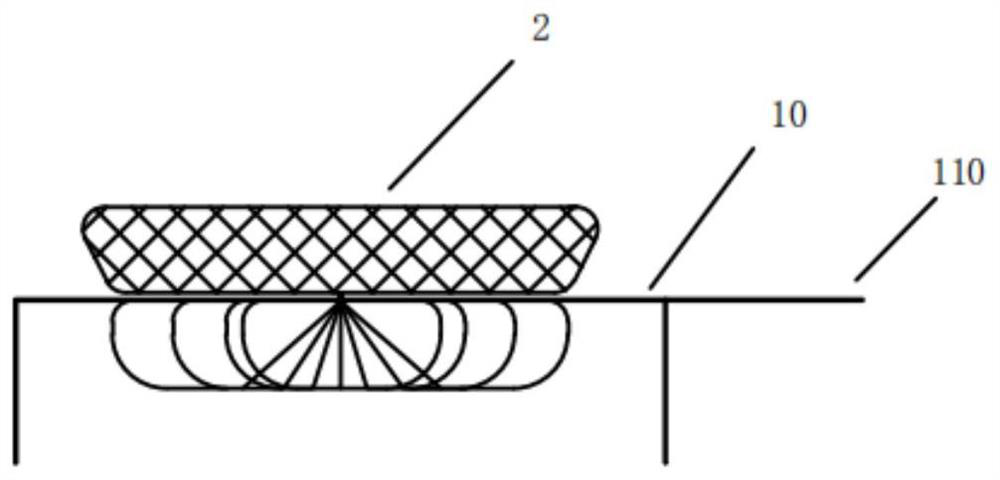

[0089] Figure 1a Shown is a schematic diagram of a packaging liner 1 in this embodiment, including a carrying plate 10 and a limiting member 11, a storage slot 100 is provided on the loading plate 10, and the object to be packaged 2 is at least partially placed in the storage slot 100 The limiting member 11 includes a fitting part 113 and a gripping part 114. The fitting part 113 is at least partly fitted to the bearing plate 10. The gripping part 114 can be freed from the bearing plate 10. The bearing plate 10 is provided with a The groove structure 12 that cooperates with the joint portion 113 realizes the assembly and disassembly functions of the two through horizontal sliding. With respect to the carrier plate 10, the sliding direction of the limiting member 11 is not parallel to the initial direction of taking out the packaged object 2, and the sliding direction is defined. The angle between the direction and the initial direction of taking out is θ, and θ satisfies the f...

Embodiment 2

[0092] like Figure 4a and 4b As shown, this embodiment is based on Embodiment 1. The difference between this embodiment and Embodiment 1 is that: one end of the fitting part 113 of the limit drawer 110 is provided with a limit protrusion 1101, which is used to realize the limit drawer The gripping part 114 of 110 moves in a single direction relative to the carrier plate 10, which is convenient for the operator to intuitively judge the extraction direction of the limit drawer 110. The other end of the fitting part 113 is provided with a protruding structure 1100. The protruding structure 1100 and The hole groove 101 on the carrier plate 10 adopts interference fit or transition fit, which is used to prevent the joint part 113 and the carrier plate 10 from sliding or shaking in a natural state, and can effectively protect the object to be packaged 2, such as Figure 4a and 4b shown.

[0093] At this time, define the horizontal spacing between the limiting protrusion 1101 and ...

Embodiment 3

[0097] like Figure 9a and 9b As shown, this embodiment is based on Embodiment 1. The difference between this embodiment and Embodiment 1 is that there is only one hole 101 on the carrier plate 10, and the bonding part 113 of the limit drawer 110 is a flat piece. structure, the fitting part 113 of the limit drawer 110 is provided with a quick-insert structure 1102, and the quick-inserting structure 1102 makes the fitting part 113 elastically deformed, so as to improve the release force between the fitting part 113 and the hole 101 , to realize the convenient assembly of the limit inserting strip 110 interspersed with the carrying plate 10; one end of the joint part 113 of the limit drawing strip 110 is provided with a protruding structure 1100, which is used to prevent the limit drawing strip 110 from being in contact with the carrying plate 10 Sliding or shaking occurs naturally.

[0098] At this time, define the maximum horizontal distance between the protruding structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com