Dyeing device for knitwear processing

A technology for needled textiles and dyeing devices, which is applied in the direction of textiles and papermaking, textile material processing, and textile material drums, etc. It can solve the problems of poor dyeing effect of needled textiles and the inability to guarantee dyeing uniformity, and achieve the goal of improving dyeing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

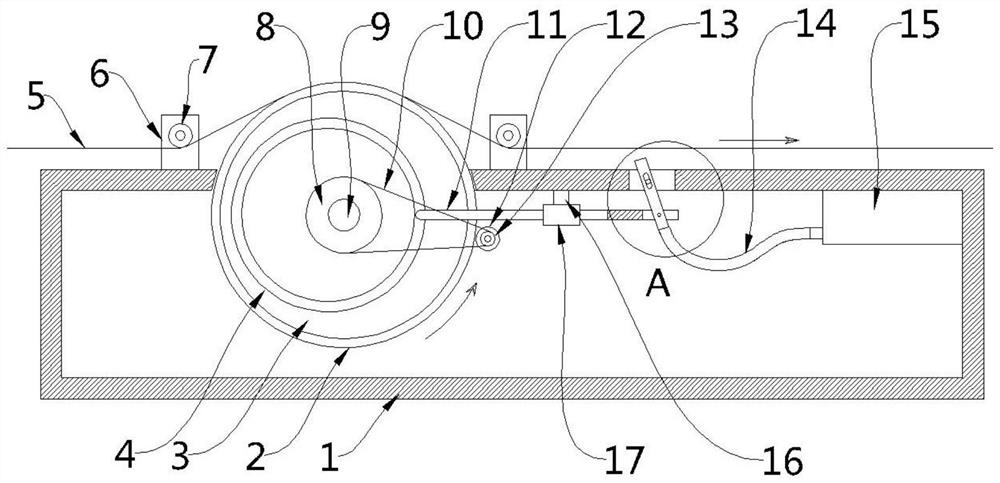

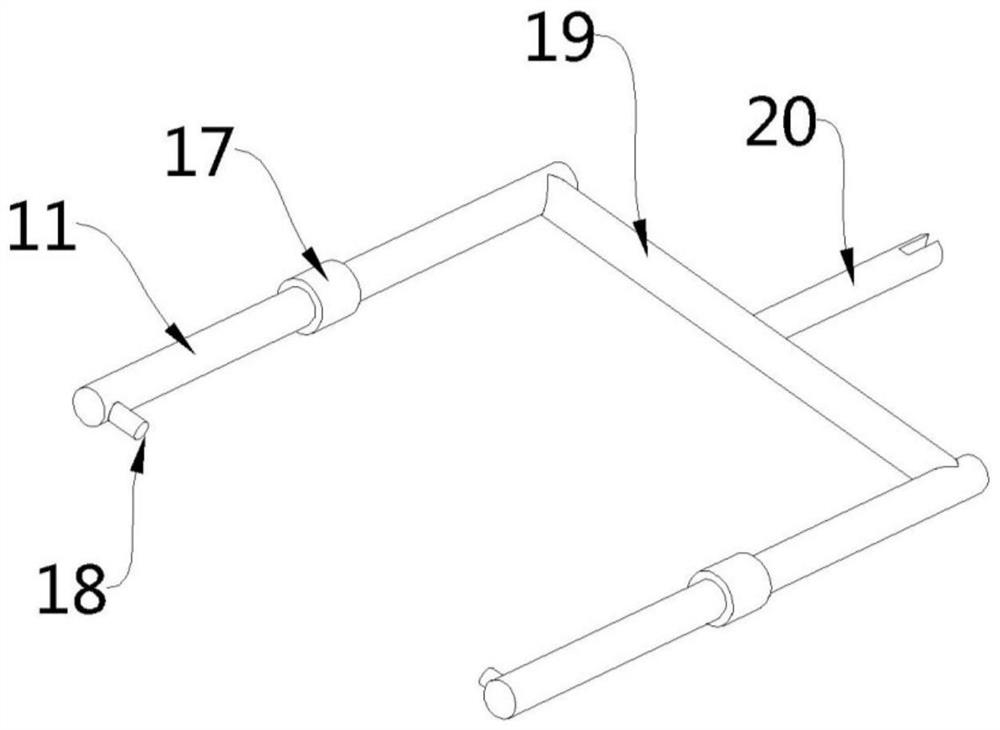

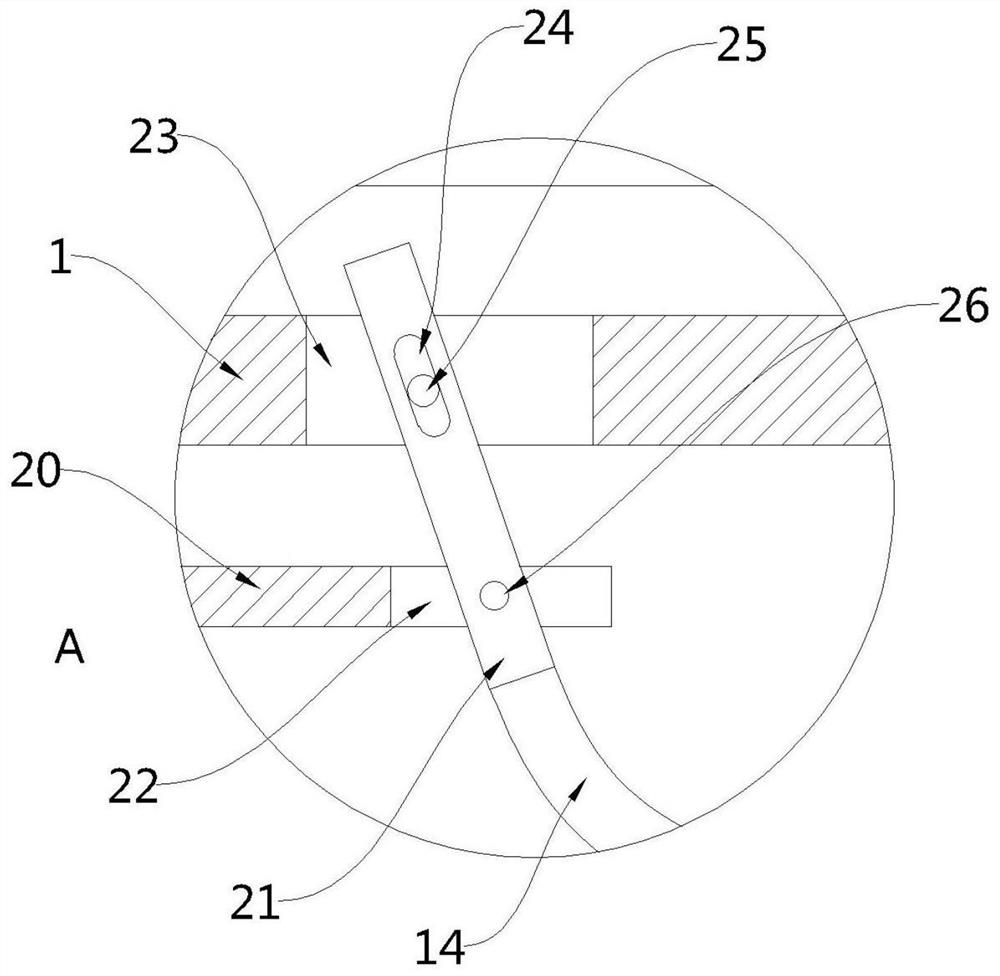

[0026] see Figure 1-3 , this embodiment provides a dyeing device for knitted textile processing, including a box body 1, the box body 1 contains dyeing agent, and a rotating roller 3 is rotated inside the box body 1, and the rotating roller 3 has a part located in the box body 1. Outside the upper part of the body 1, the middle part of the rotating roller 3 penetrates and is fixedly provided with a rotating shaft 9, one end of the rotating shaft 9 is connected with an external motor (not shown), the upper part of the box body 1 is provided with a through hole 23, and the interior of the through hole 23 A nozzle 21 is movably arranged, and an air supply assembly for introducing hot air into the nozzle 21 and a transmission for driving the nozzle 21 to swing back and forth along the through hole 23 are arranged inside the box 1 Specifically, the transmission assembly includes two sets of relatively distributed first push rods 11 , a cross rod 19 fixedly connected to one end of ...

Embodiment 2

[0039] see figure 1 , a dyeing device for needle textile processing. Compared with Embodiment 1, the upper part of the box body 1 is symmetrically distributed with two groups of brackets 6 with respect to the rollers 3, and one side of the brackets 6 of the two groups is A pressing roller 7 is arranged for rotation, and the horizontal plane of the bottom of the pressing roller 7 is located below the horizontal plane of the upper part of the turning roller 3 .

[0040] When the needled textile 5 moves horizontally along the upper part of the box body 1, two sets of pressure rollers 7 can be used to squeeze the needled textile 5, so as to squeeze the needled textile 5 on the upper part of the rotating roller 3, thereby increasing the contact between the needled textile 5 and the rotating roller 3. The contact effect between ensures that there is sufficient contact area between the needle textile 5 and the rotating roller 3, thereby ensuring the dyeing effect.

[0041] The embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com