Assembly type floor slab convenient to level

A prefabricated and floor-slab technology, applied to floors, building components, buildings, etc., can solve problems such as difficult leveling, low efficiency, and difficult to guarantee effects, and achieve low construction level requirements, simple leveling operations, and avoid separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

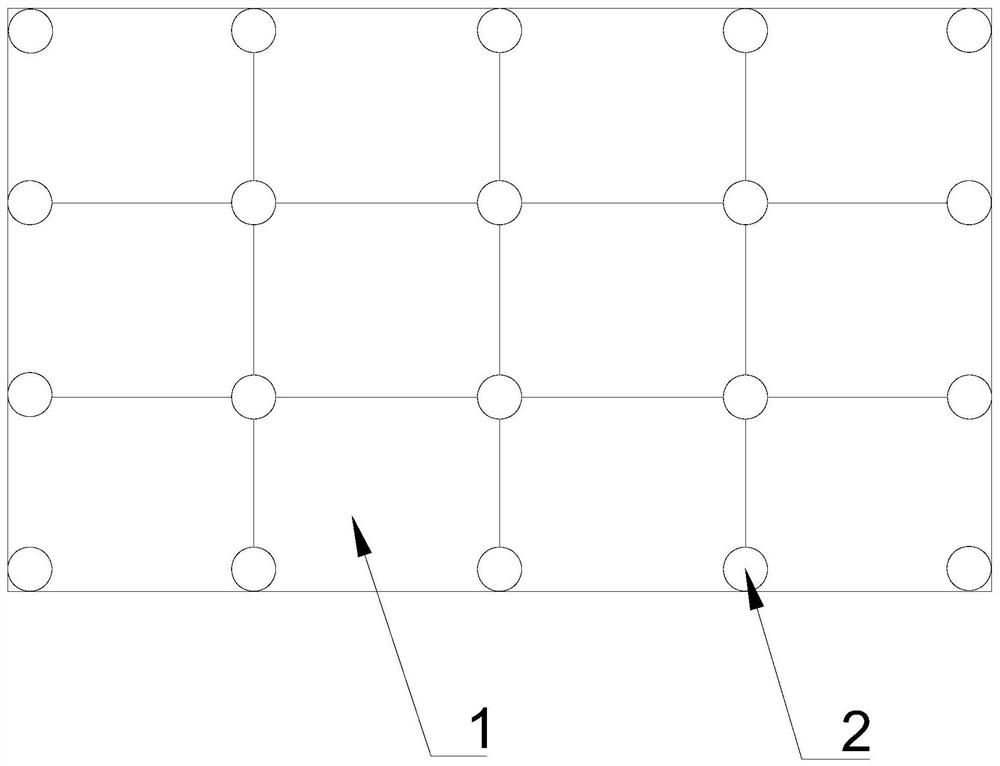

[0037] refer to figure 2 As shown, a prefabricated floor slab that is easy to level in this embodiment includes a prefabricated slab 1 and a fixing assembly 2 for fixing the prefabricated slab 1 to the ground, and the prefabricated slab 1 is fixed on the ground through the fixing assembly 2 .

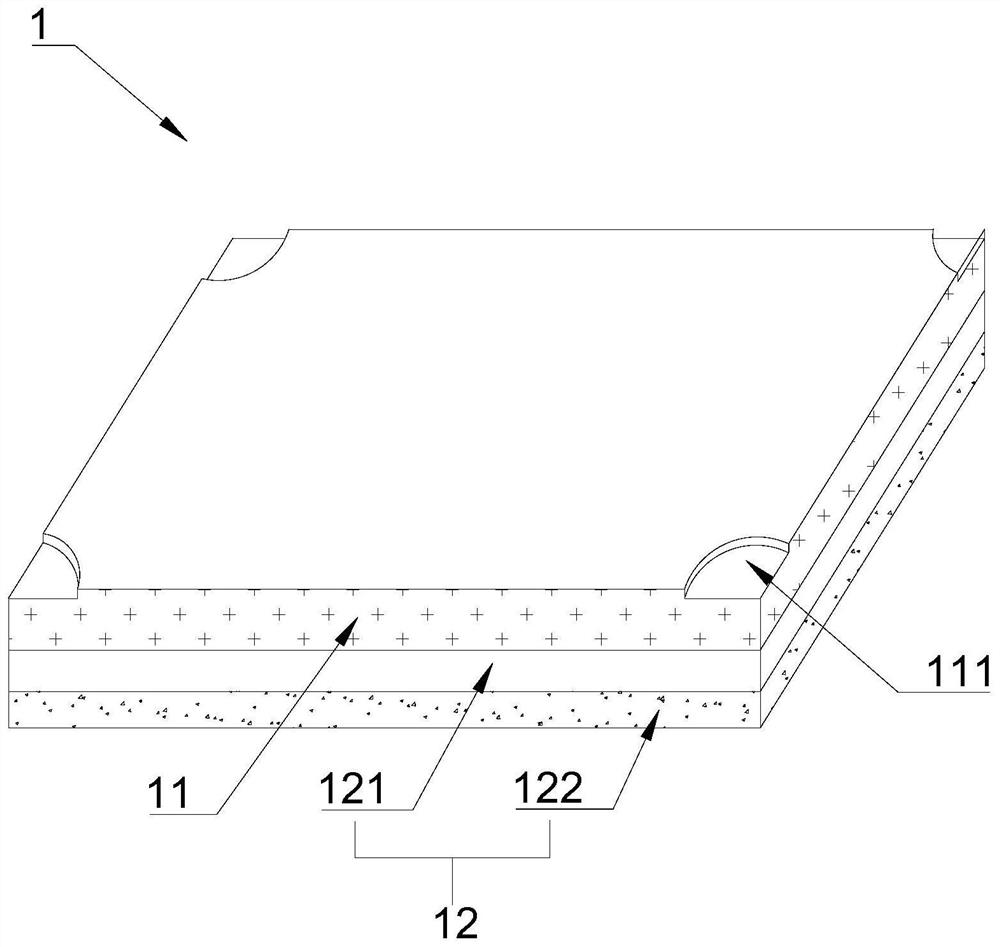

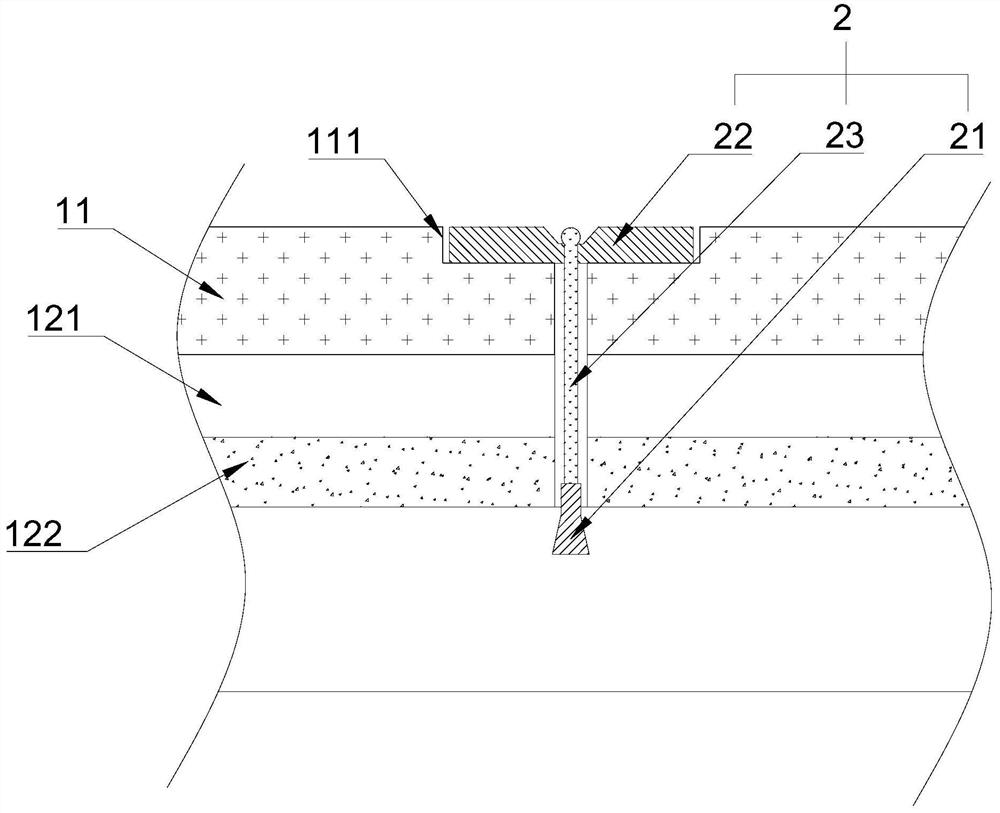

[0038] refer to figure 1 , image 3 As shown, the prefabricated panel 1 includes a protective surface layer 11 and a functional layer 12 connected to each other. The protective surface layer 11 is made of cementitious material (cement, gypsum, etc.), aggregate (sand, light sand, light aggregate, etc.) Composite pressing, it has a certain strength, the protective surface layer 11 is located on the uppermost layer, and plays the role of protecting the functional layer 12. The protective surface layer 11 can be made of terrazzo, and can also be combined with decorative layers such as ceramic tiles.

[0039] refer to figure 1 , image 3 As shown, the functional layer 12 in this embodi...

Embodiment 2

[0045] The difference between the second embodiment and the first embodiment is as follows. refer to Figure 4 , Image 6 As shown, the specific structure of the fixing assembly 2 is as follows: the fastener 21 is set as an expansion bolt, and the extrusion piece 22 is set as a disc. The connector 23 includes an inner rod 231 and an outer rod 232 that are inserted into each other. The other ends of the inner rod 231 and the outer rod 232 are respectively fixed on the fastener 21 or the extruded part 22, that is, when the inner rod 231 is connected with the expansion bolt , the outer rod 232 is connected with the extruded part 22; when the inner rod 231 is connected with the extruded part 22, the outer rod 232 is connected with the expansion bolt. In this embodiment, the inner rod 231 is connected with the expansion bolt, and the outer rod 232 is connected with the extruded part 22 .

[0046] refer to Figure 4 , Image 6 As shown, the socket of the outer rod 232 is provid...

Embodiment 3

[0050] The difference between embodiment two and embodiment two is: with reference to Figure 5 As shown, the fastener 21 is arranged in a plate shape, and the lower surface of the fastener 21 is bonded to the ground by glue. During construction, the lower surface of the fastener 21 and the ground are directly bonded with glue, so as to complete the fixing between the fastener 21 and the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com