Processing technology of normal-temperature storage type coarse-cereal-flour-doped braised noodles

A processing technology and a technology for miscellaneous grains, which are applied to the processing technology field of normal temperature storage-type mixed grain stewed noodles, can solve the problems of easy lumps, damage to human health, poor taste, etc., and achieve the effect of being convenient for storage and maintaining the taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A processing technology for normal temperature storage type doped grain stewed noodles, comprising the following steps:

[0050] S1, preparation of braised noodles, comprising the following steps:

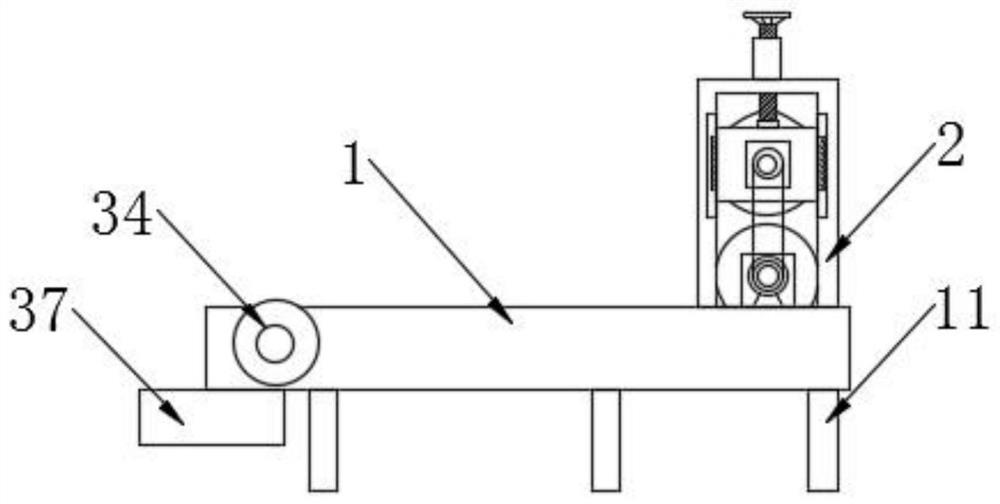

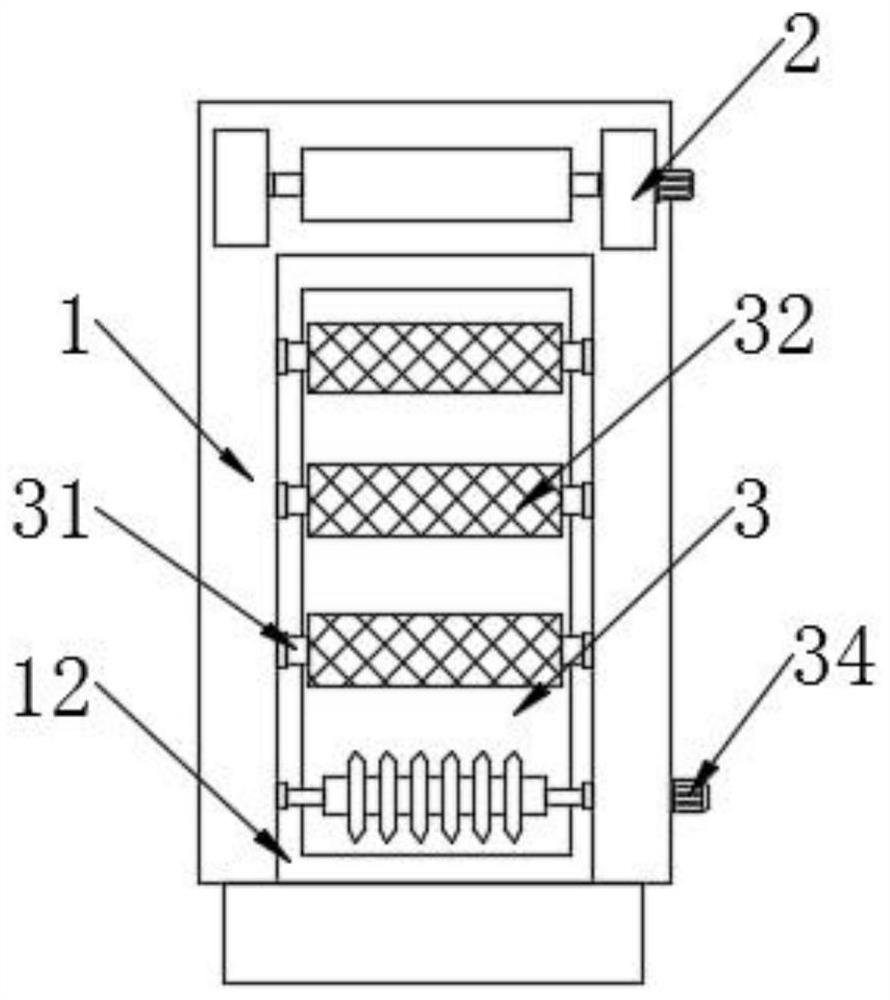

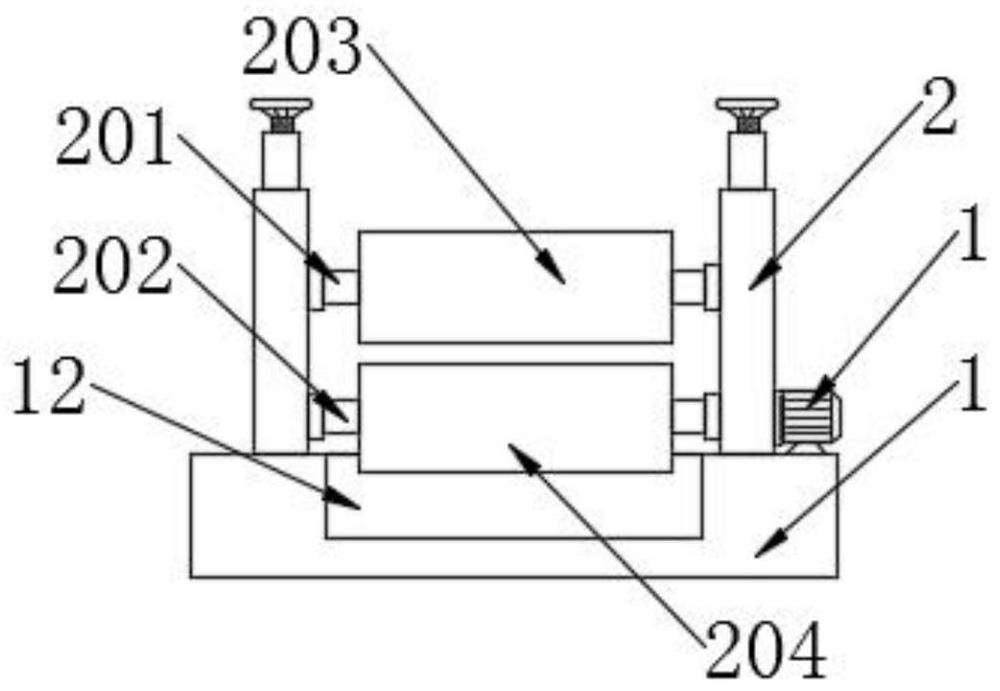

[0051] S11. Knead the mixed grain flour to form dough, put the dough into the dough processing device for dough processing to make noodles;

[0052] S12. Cook and mature the noodles in step S11, and cover the surface of the matured noodles with water;

[0053] S13. Dispersing the water-covered noodles in step S12 with edible oil to form an oil film on the surface of the noodles to obtain stewed noodles;

[0054] S2. Dish preparation, after the dishes are washed, treated at high temperature to reduce bacteria, stir-fried and seasoned, the finished dishes are obtained;

[0055] S3. Mix the stewed noodles in S1 with the dishes in S2 to obtain a mixture. After the mixture is stirred, sterilized at high temperature, and vacuum-packed, a normal temperature storage type mixed gra...

Embodiment 2

[0062] A processing technology for normal temperature storage type doped grain stewed noodles, comprising the following steps:

[0063] S1, preparation of braised noodles, comprising the following steps:

[0064] S11. Knead the mixed grain flour to form dough, put the dough into the dough processing device for dough processing to make noodles;

[0065] S12. Cook and mature the noodles in step S11, and cover the surface of the matured noodles with water;

[0066] S13. Dispersing the water-covered noodles in step S12 with edible oil to form an oil film on the surface of the noodles to obtain stewed noodles;

[0067] S2. Dish preparation, after the dishes are washed, treated at high temperature to reduce bacteria, stir-fried and seasoned, the finished dishes are obtained;

[0068] S3. Mix the stewed noodles in S1 with the dishes in S2 to obtain a mixture. After the mixture is stirred, sterilized at high temperature, and vacuum-packed, a normal temperature storage type mixed gra...

Embodiment 3

[0075] A processing technology for normal temperature storage type doped grain stewed noodles, comprising the following steps:

[0076] S1, preparation of braised noodles, comprising the following steps:

[0077] S11. Knead the mixed grain flour to form dough, put the dough into the dough processing device for dough processing to make noodles;

[0078] S12. Cook and mature the noodles in step S11, and cover the surface of the matured noodles with water;

[0079] S13. Dispersing the water-covered noodles in step S12 with edible oil to form an oil film on the surface of the noodles to obtain stewed noodles;

[0080] S2. Dish preparation, after the dishes are washed, treated at high temperature to reduce bacteria, stir-fried and seasoned, the finished dishes are obtained;

[0081] S3. Mix the stewed noodles in S1 with the dishes in S2 to obtain a mixture. After the mixture is stirred, sterilized at high temperature, and vacuum-packed, a normal temperature storage type mixed gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com