A disc tube type reverse osmosis component

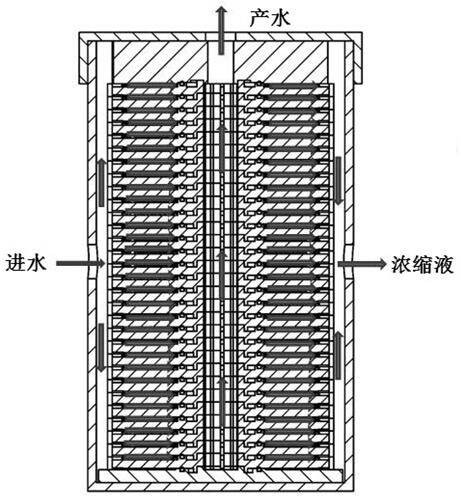

A disc-type reverse osmosis and component technology, which is applied in osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, membrane technology, etc. The effect of reducing pollution and reducing concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

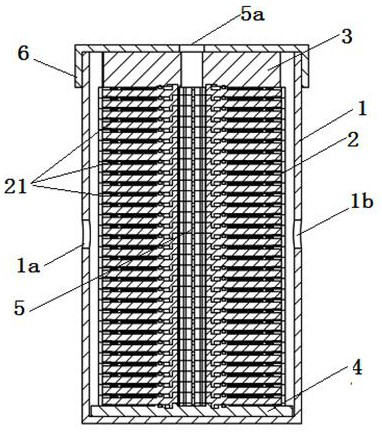

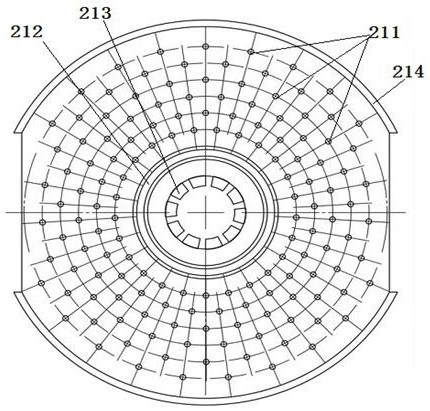

[0019] combine Figure 1-7 As shown, a disc tube type reverse osmosis assembly of the present invention includes a membrane shell 1, a membrane core 2 inside the membrane shell, and upper and lower flanges 3 and 4 at both ends of the membrane shell. It is characterized in that: the membrane core 2 includes A number of superimposed guide plates 21, one side of the guide plate is provided with a number of bumps 211 and a sealing ring groove 212, the other side of the plate is welded with a reverse osmosis diaphragm 215, and the sealing ring groove 212 is equipped with an O-ring for the diaphragm Sealing, two adjacent diversion discs are connected by positioning bosses 213 on the inner holes of the diversion discs in an engaging manner, and the inner holes of the superimposed diversion discs form a water production channel 5, and the periphery of the diversion disc surface is the outer The ring platform 214 and the outer ring platform 214 are provided with two gaps, and the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com