Coordinate conversion method of aero-engine blade repair system based on visuo-tactile coordination

An aero-engine and coordinate transformation technology, applied in plasma welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as failure to meet precision requirements, achieve clear transformation relations, improve precision, and intuitive coordinate transformation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the specific drawings, which do not limit the scope of protection of the present application.

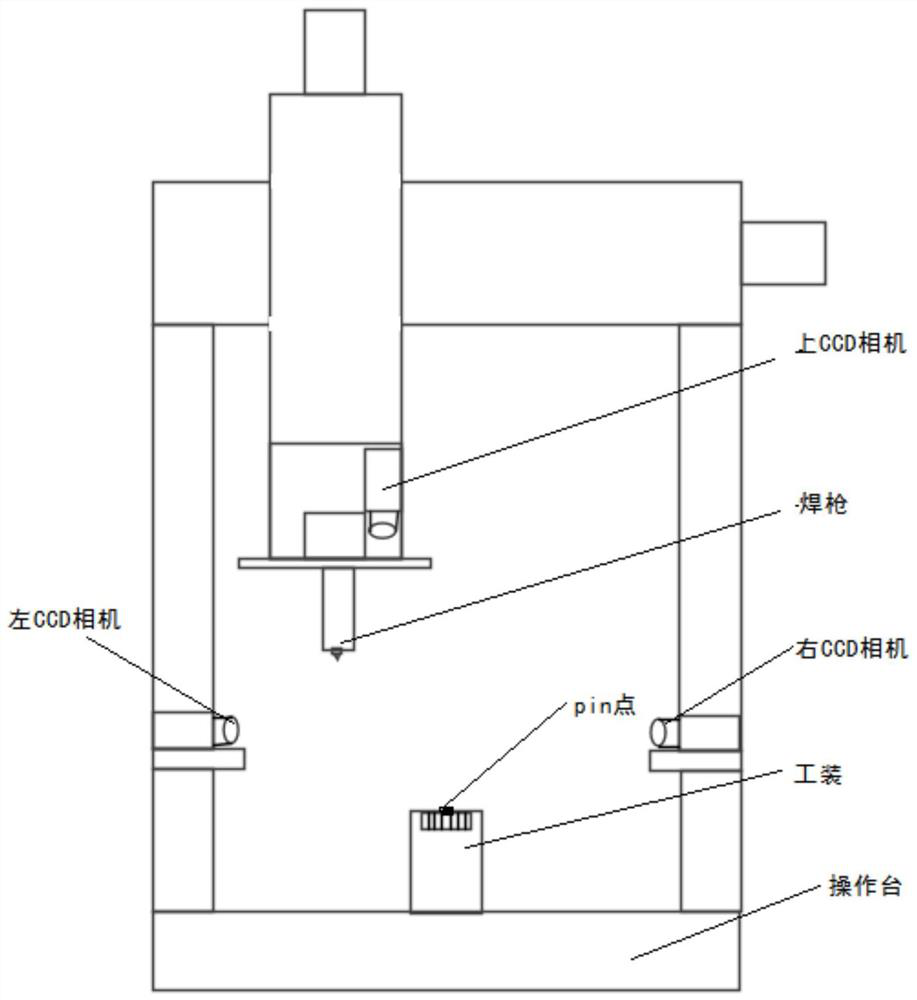

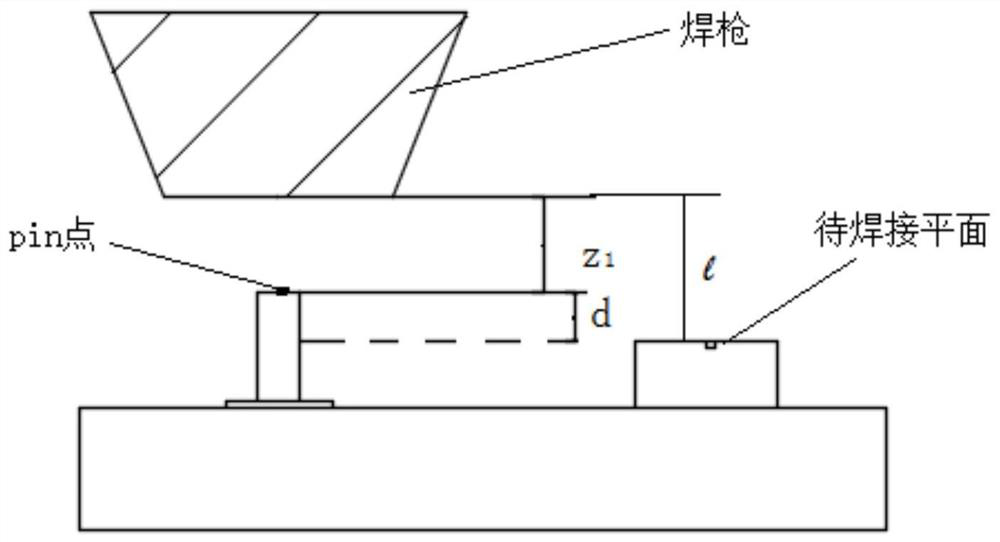

[0031] The present invention is a coordinate transformation method (method for short, see Figure 1-2 ), wherein the aero-engine blade repair system includes a welding torch, tooling, a host computer and three CCD cameras; the tooling is installed on the console, the tooling is equipped with an aero-engine blade, the tooling is provided with a boss, and a pin point is provided on the boss (reference point); three CCD cameras are respectively installed on the welding torch and on the left and right sides of the console, and the pin point is located at the intersection of the sight lines of the two CCD cameras on the left and right.

[0032] The method includes the following steps:

[0033] Step 1. Determine the coordinates of the pin point and the origin of the image coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com