Novel anti-shaking galvanometer mechanism

A new type of anti-shake technology, applied in the field of laser marking machines, can solve problems such as insufficient anti-shake performance, and achieve the effects of improving anti-shake performance, reducing weight and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

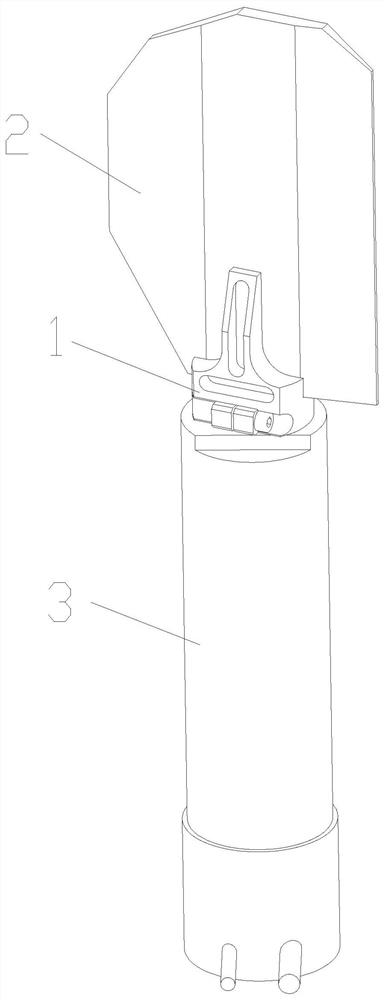

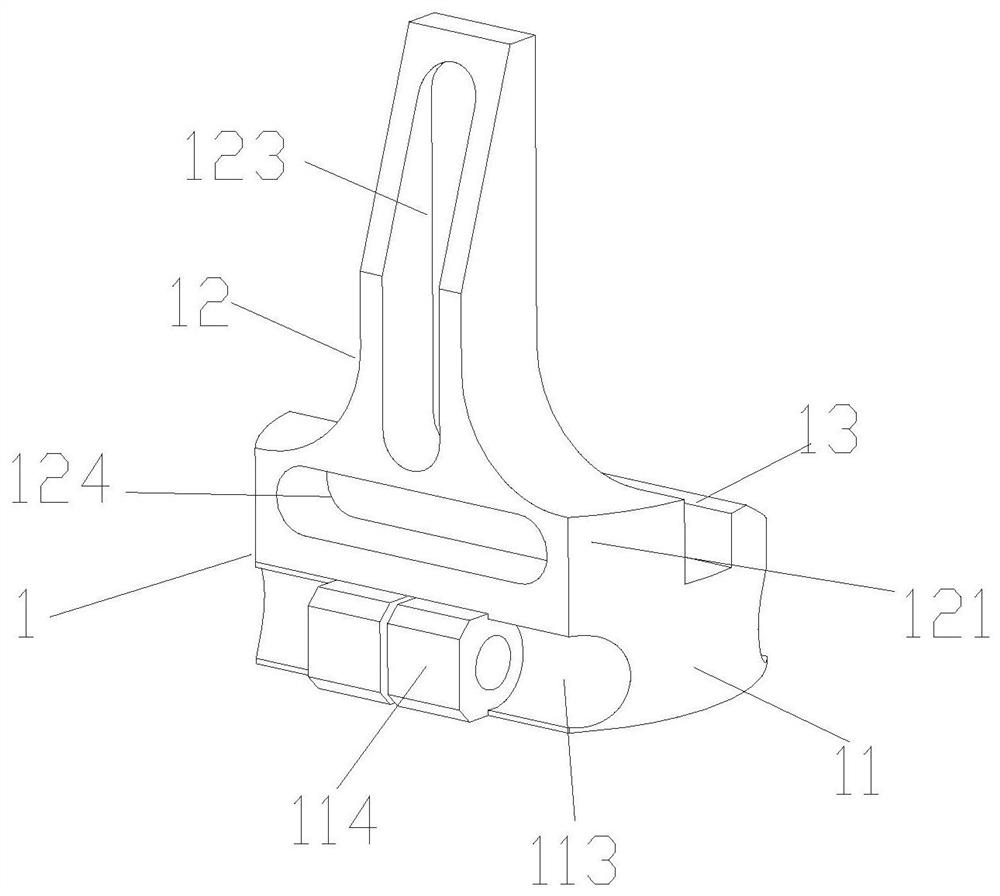

[0059] One of the embodiments of the present invention, such as Figure 1~5 As shown, this embodiment provides a novel anti-shake vibrating mirror mechanism, including an anti-shake chuck 1 and a vibrating mirror 2; The mirror support end 12; the bottom of the base 11 is provided with a shaft hole 11a for connecting with the output shaft of the motor, so that the anti-shake chuck 1 is connected with the motor 3 through the shaft hole 11a;

[0060] The vibrating mirror 2 is made of aluminum or aluminum alloy; one side of the vibrating mirror 2 is coated with a reflective film to form a mirror surface, and the other side is formed as a connecting surface 21; one end of the vibrating mirror 2 is used for The shaking chuck 1 is connected, and the rotation axis is located in the vibrating mirror 2, parallel to the mirror surface;

[0061] The shaft hole 11a at the bottom of the base 11 is formed by connecting a movable locking block 111 and an axial end 112 fixed to the base 11; t...

Embodiment 2

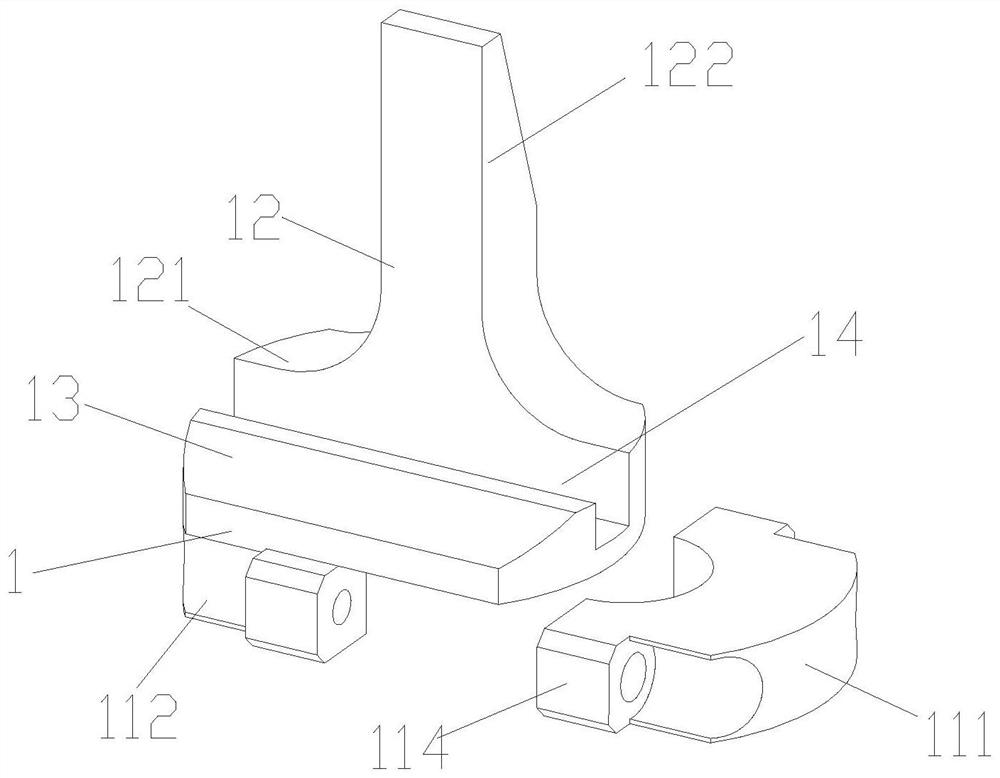

[0079] One of the embodiments of the present invention, such as Figure 6-8 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0080] The supporting end 12 of the vibrating mirror is set in a rectangular plate shape; wherein, the side facing the groove of the supporting end 12 of the vibrating mirror is set to be connected with the connecting surface of the vibrating mirror 2, so that the vibrating mirror 2 is fixed on the anti-shake chuck 1 The other side of the galvanometer support end 12 is provided with two concave vertical grooves 123; the wall between the two vertical grooves 123 is formed as a reinforcing rib;

[0081] The supporting end 12 of the vibrating mirror is arranged symmetrically on both sides of the axis; the connecting surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com