Three-dimensional pattern sponge cutting machine

A sponge cutting machine and pattern technology, applied in metal processing and other directions, can solve the problems of complex and troublesome installation structures, and achieve the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

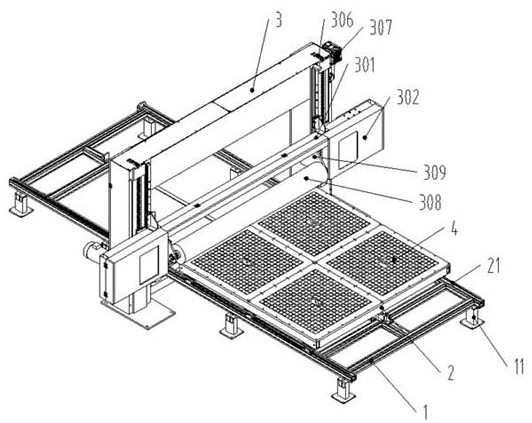

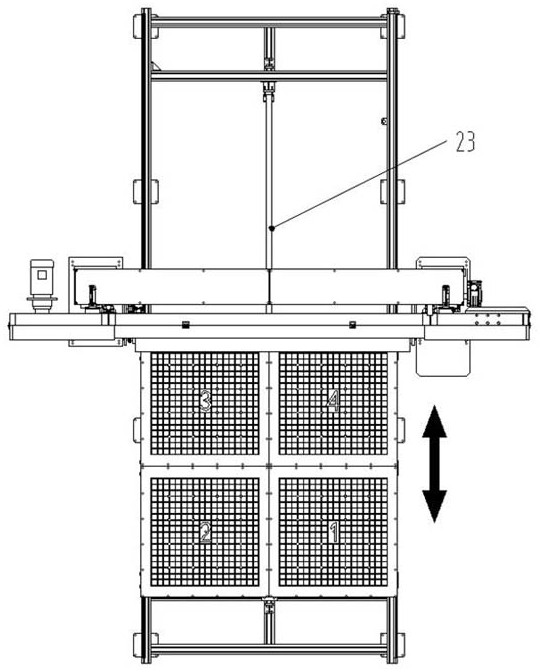

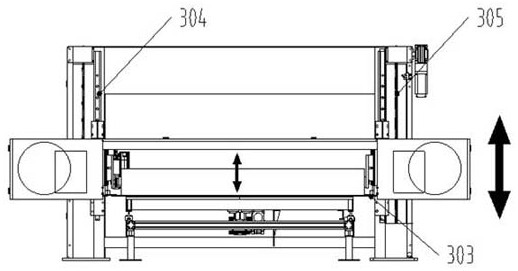

[0029] Such as Figure 1-Figure 6 A three-dimensional pattern sponge cutting machine shown, including

[0030] A processing support 1, the processing support 1 is a rectangular frame structure composed of several horizontal bars and vertical bars, and several supporting feet 11 are connected to the bottom end of the processing support 1.

[0031] A conveying unit installed on the processing support 1, the conveying unit includes a conveying platform 2, the conveying platform 2 is a rectangular plate, and the conveying platform 2 is driven by a conveying drive mechanism to reciprocate along the long axis of the processing support 1.

[0032] The conveying drive mechanism is as follows: a horizontal translation guide rail 21 is installed on both sides of the processing suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com