Hybrid laminar flow wing air suction energy loss engineering calculation method

A technology of energy loss and engineering calculation, applied in the direction of air flow, aircraft parts, aircraft control, etc. that affects the surface of the aircraft, it can solve the problems such as the inability to carry out the design of aircraft performance indicators, the lack of them, and achieve the effect of fine and comprehensive calculation model.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

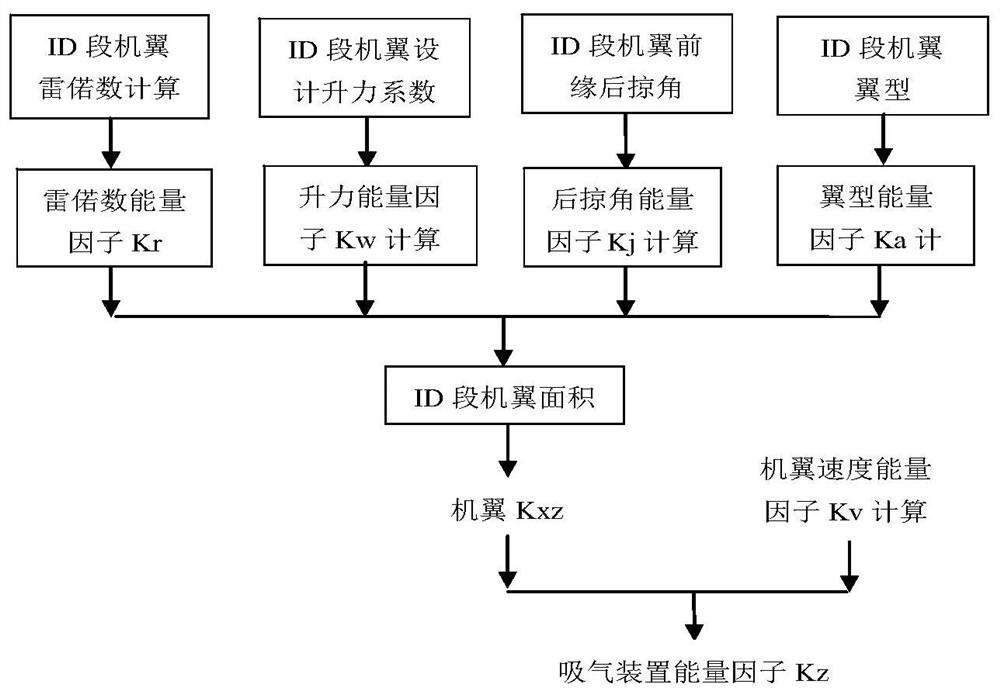

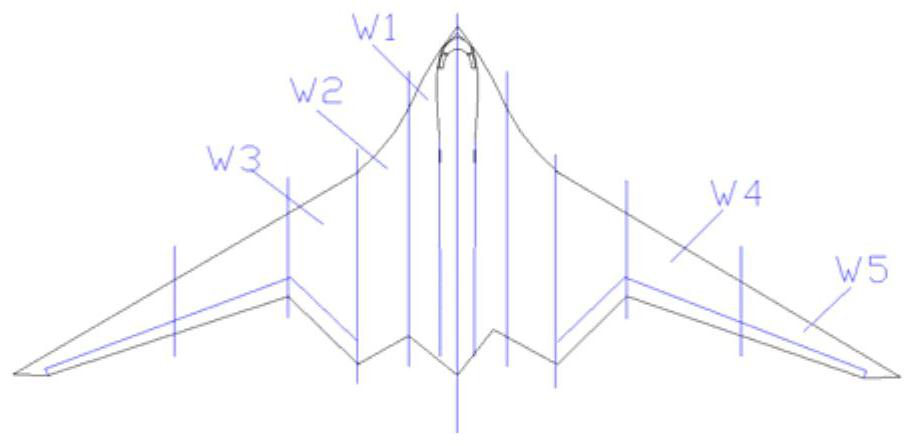

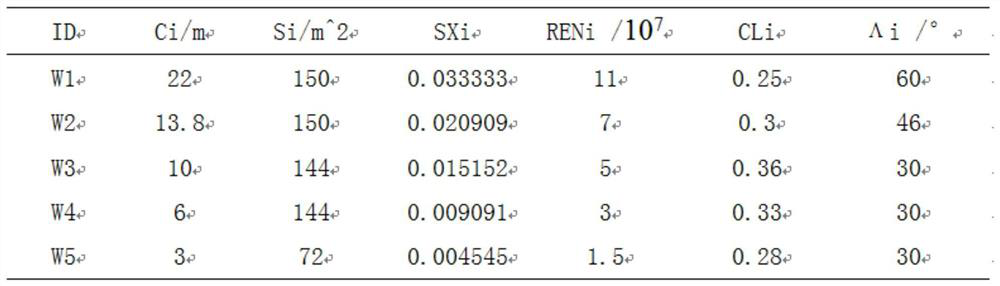

[0041] An engineering calculation method for air intake energy loss of a mixed laminar flow wing. According to CFD calculation data, wind tunnel test data and flight test data analysis, the Rero number REN, lift coefficient CL, wing leading edge sweep Angle Λw and cruising Mach number are the engineering calculation function of the energy loss factor of the wing suction device; taking the position of the upper and lower wing layer flow transition obtained from the X21 flight test as a reference, the eN wing boundary layer flow transition considering suction is used The position calculation method calculates the energy loss factor produced by the mass of the airfoil, and finally obtains the energy loss factor of the wing suction device of the whole aircraft by summing the area integral of the energy loss factor of the wing span t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com