Sheet type carton packaging machine

A packaging machine and carton technology, applied in packaging, packaging bottles, transportation packaging, etc., can solve the problems of slow production and packing speed, achieve the effects of increasing speed, easy preparation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

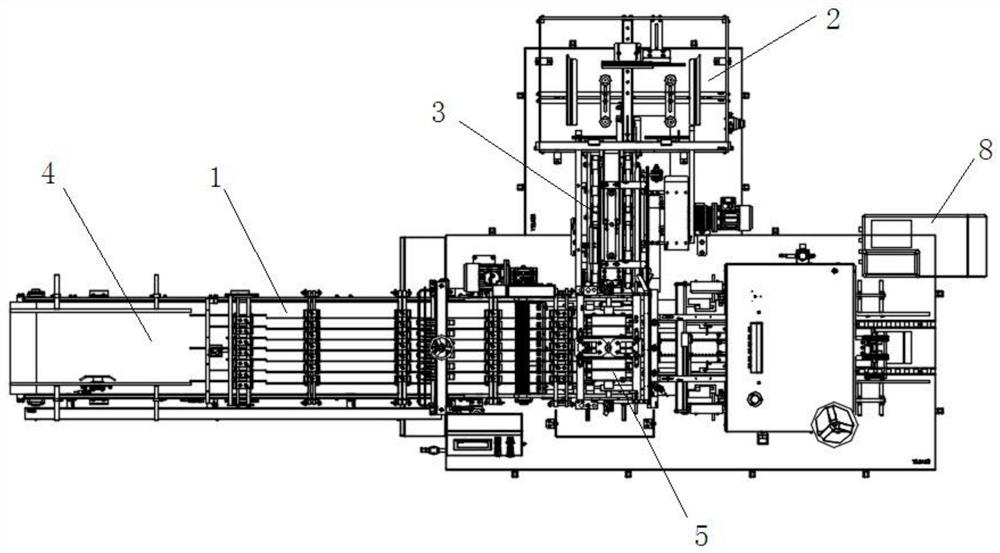

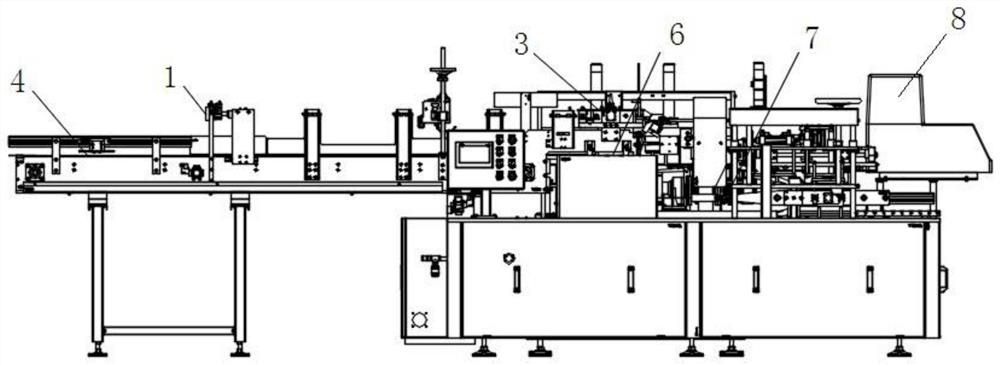

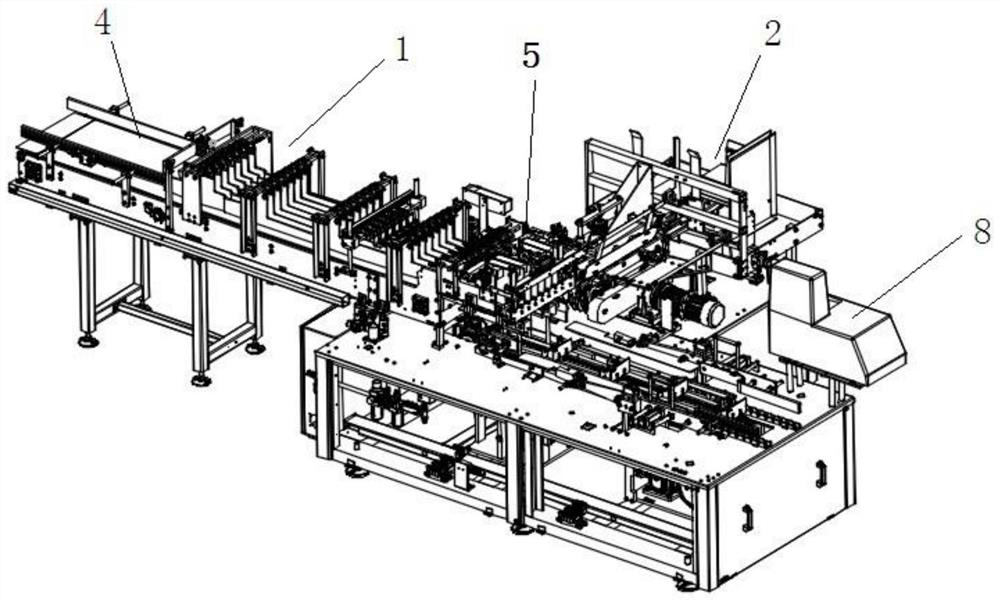

[0022] In order to illustrate the technical scheme of the present invention more clearly, the following will be combined with the attached Figure 1-8 Embodiment 1 of the present invention is further described.

[0023] A sheet-type carton packaging machine, including: grouping and arranging device 1, paper storage device 2, paper pushing device 3, can body conveying line 4, can pushing device 5, blanking forming device 6, tongue folding device 7, glue spraying Device 8 and pre-folding mechanism 9.

[0024] The input end of the grouping and arranging device 1 is connected to the tank body conveying line 4, and the tank bodies input on the tank body conveying line 4 are grouped and arranged; the can pushing device 5 is located at the output end of the grouping and arranging device 1, and moves along the vertical direction;

[0025] The blanking forming device 6 is located below the can pushing device 5, and the blanking forming device 6 includes a blanking suction cup 61, a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com