Garbage can and cleaning method thereof

A technology of a trash can and a barrel body, applied in the field of trash cans, can solve the problems of perishable garbage, high labor cost, and increased temperature of the trash can, so as to improve the efficiency and effect of cleaning, ensure the effect and area of wetting, avoid The effect of waste degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

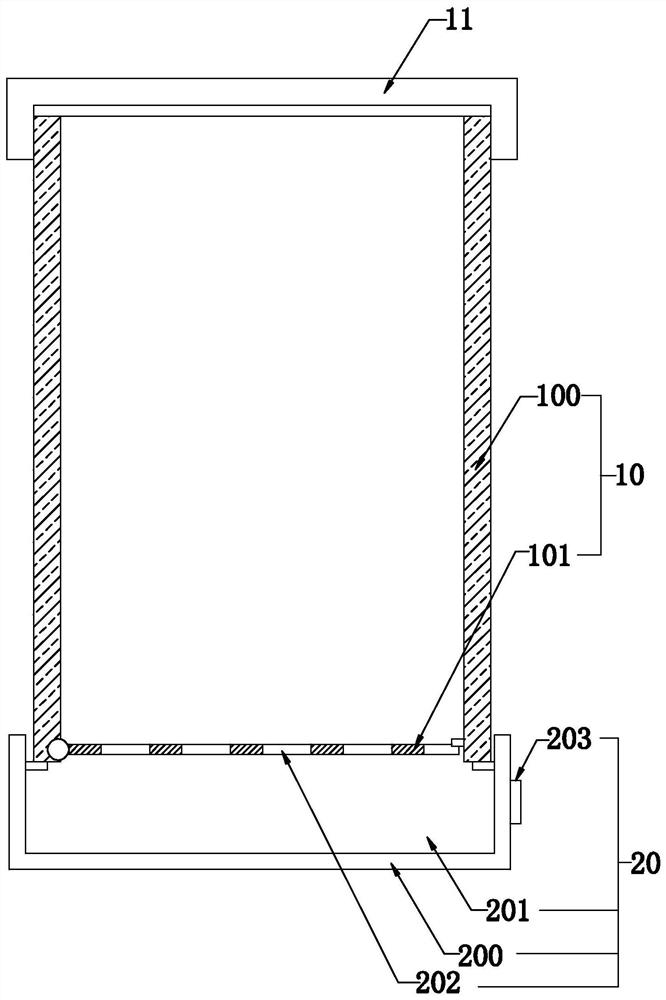

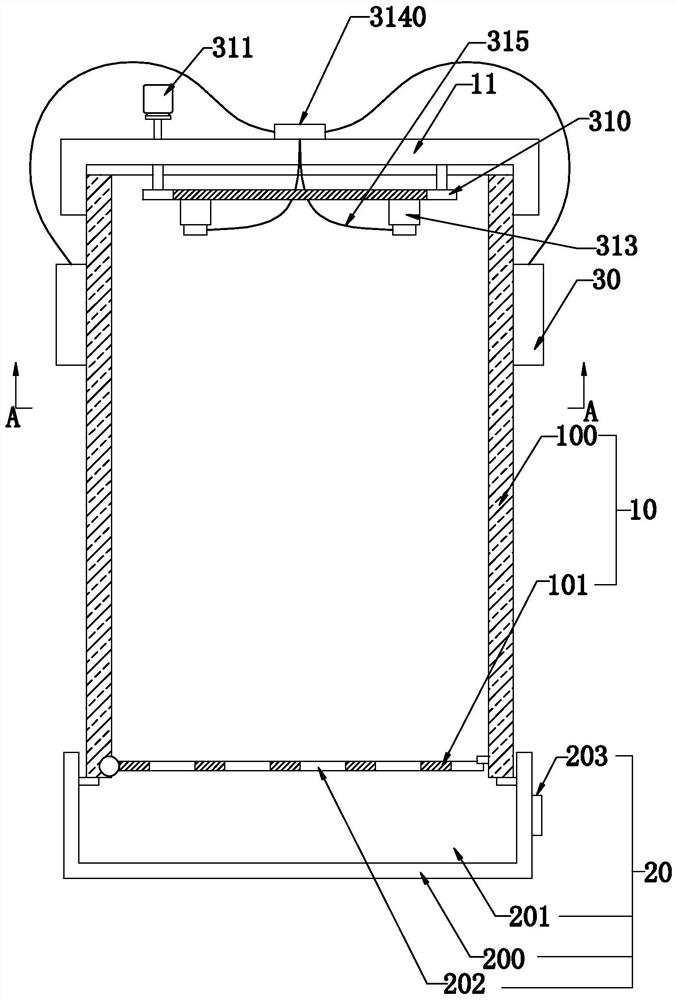

[0044] Such as figure 1 As shown, the present invention discloses a trash can, including a barrel body 10 and a barrel cover 11 installed on the top of the barrel body 10. In a specific embodiment of the present invention, the barrel body 10 includes an upper end and a lower end as An open body 100 and a support plate 101 provided at the opening of the lower end of the body 100 and hinged on any side with the body 100 and at least one side is detachably connected to the body 100; When the hinge of the main body 100 is turned over and the opening at the lower end of the main body 100 is opened, the garbage in the main body 100 can be discharged through the opening at the lower end of the main body 100 .

[0045] In a specific embodiment of the present invention, it also includes a drainage structure 20 arranged at the bottom of the body 100 and used to support the body 100; wherein, the drainage structure 20 includes a base 201 having a cavity 200 and used to support the body 1...

Embodiment 2

[0050] Embodiment 2, the difference with embodiment 1 is:

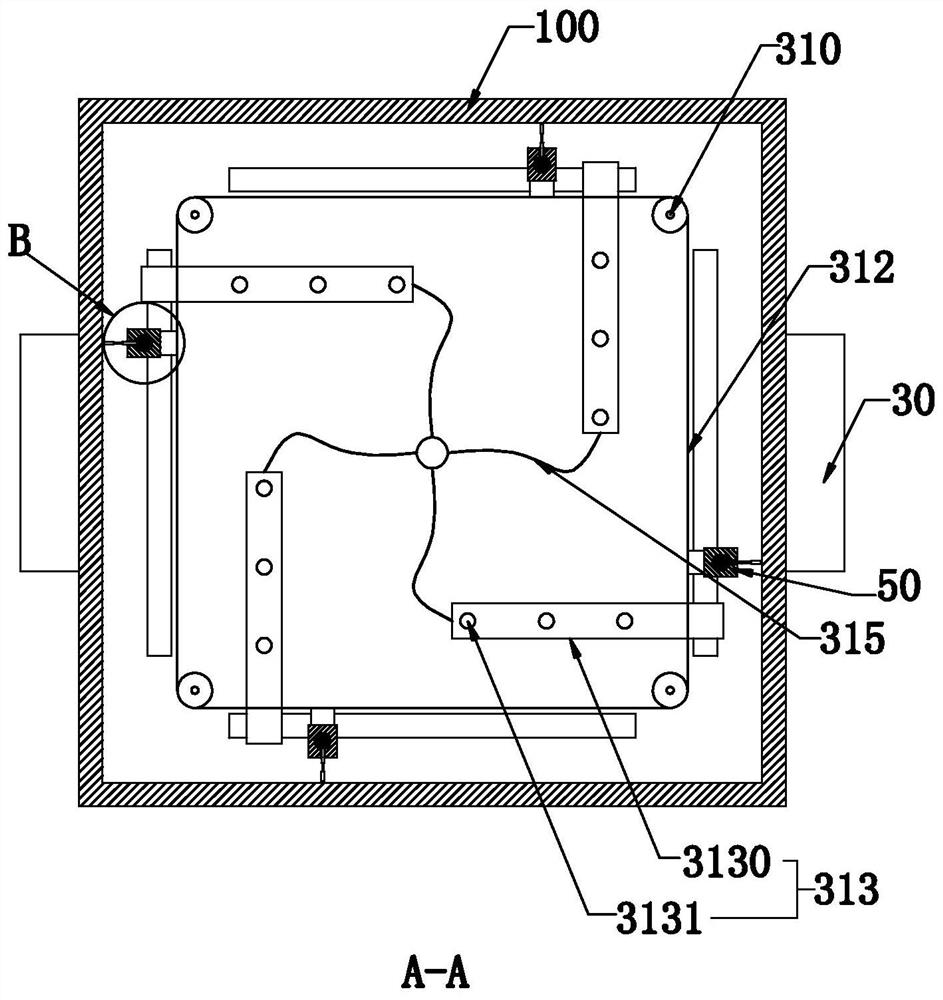

[0051] Such as Figure 2-Figure 8 As shown, in the specific embodiment of the present invention, it also includes a water storage body 30 installed on the body 100 and a cleaning device installed on the bucket cover 11 and supplied with water through the water storage body 30; wherein, the cleaning device includes At least three transmission wheels 310 that are rotatably connected to the bucket cover 11 and distributed at equidistant intervals from the axis of the body 100 and driven by a motor 311, a synchronous transmission belt 312 that is transmission connected to each transmission wheel 310, and several transmission wheels installed on the The water spray device 313 on the synchronous transmission belt 312 and between the adjacent transmission wheels 310 and the water supply part 314 installed on the bucket cover 11 and used to supply water to each water spray device 313 at the same time; wherein, the water suppl...

Embodiment 3

[0063]Embodiment 3, the difference with embodiment 2 is that

[0064] Such as Figure 9 As shown, in a specific embodiment of the present invention, an air supply device is also included; wherein, the air supply device includes an air supply pump installed on the barrel cover 11, an air supply main pipe connected to the output end of the air supply pump, and several An air supply branch pipe 60 connected in series with the air supply main pipe; wherein, the output end of each air supply branch pipe 60 extends and passes through the water spray port 41 of the nozzle body 40, and the water spray port 41 of the nozzle body 40 is connected from the air supply branch pipe 60 The outer wall of the pipe penetrates into the air supply branch pipe 60.

[0065] In the specific embodiment of the present invention, it also includes a control system for controlling the air supply pump and the water pump 3140; wherein, the control system includes a central control unit 70 and a first A co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com