A glass fiber reinforced PBT/PC alloy with high strength, low warpage and high heat distortion temperature and its preparation method and application

A technology of deformation temperature and high strength, applied in the field of glass fiber reinforced PBT/PC alloy and its preparation, can solve the problems of limited improvement in performance and achieve the effect of optimal tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

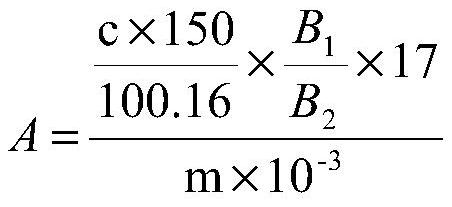

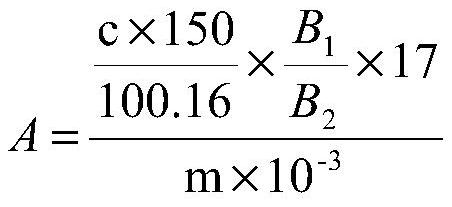

Image

Examples

Embodiment 1~18

[0053]Warpage test: Inject the PBT / PC alloy into a 100*100*1.5mm square plate, press one corner with a 1kg weight, and measure the height h from the diagonal to the horizontal plane with a vernier caliper, in mm. Embodiment 1~18 and comparative example 1~6

[0054] According to the formula of table 1~table 3, preparation embodiment 1~18 and comparative example 1~6, concrete preparation steps are as follows:

[0055] S1. Dry PBT resin and PC resin at 120-140°C for 4-6 hours;

[0056] S2. Mix the dried PBT resin and PC resin with polycarbodiimide and antioxidant in S1. Feed from the main feeding port of the twin-screw extruder, and the glass fiber is fed from the side of the twin-screw extruder. feeding port feeding;

[0057] S3. Set the temperature of each zone of the twin-screw extruder to 220-250° C. for extrusion, and the speed of the twin-screw extruder to be 300-400 rpm. ;

[0058] S4. Post-processing after extrusion to obtain the PBT / PC alloy.

[0059] The performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com