Highway bridge prestress cable penetrating machine

A highway bridge and prestressing technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to stretch, do not have automatic shearing function, etc., to extend service life, facilitate promotion, and reduce work difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

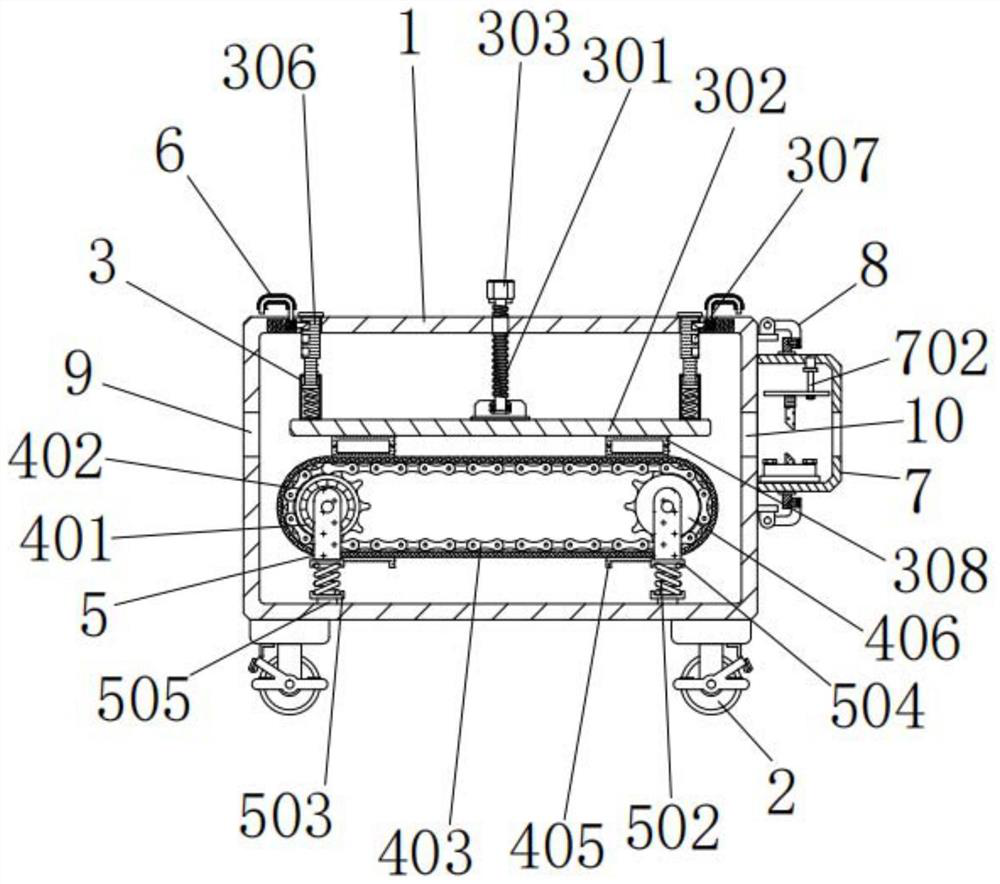

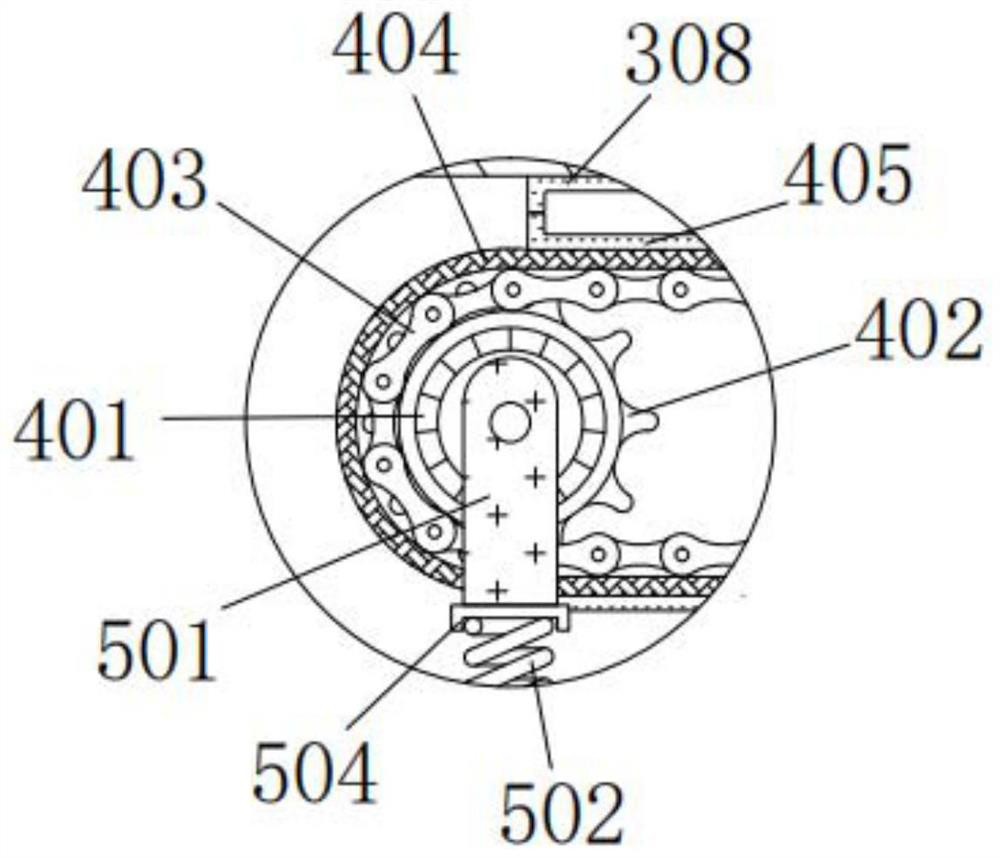

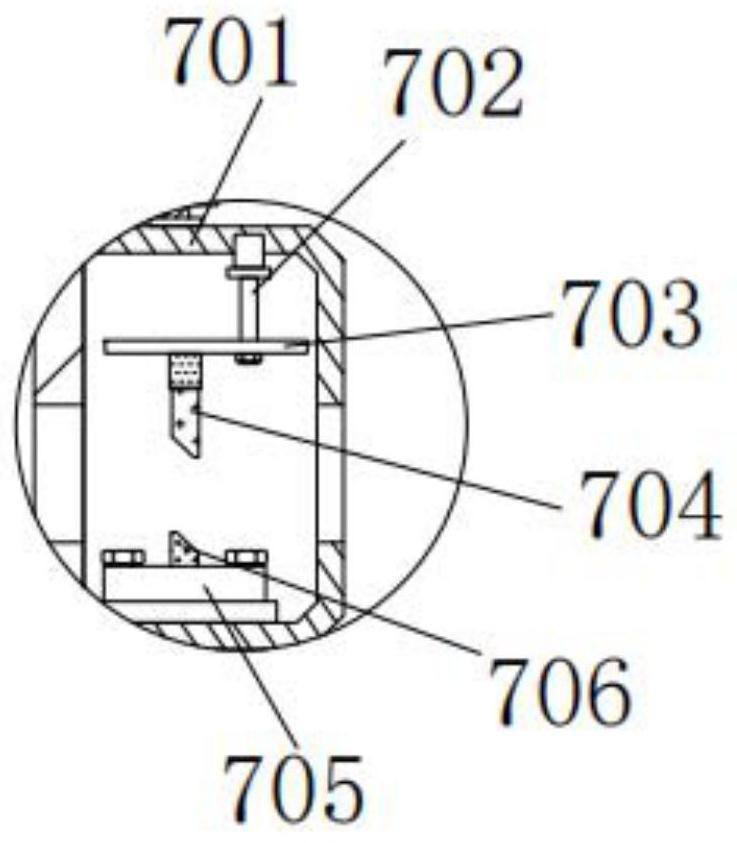

[0036]SeeFigure 1-6The present invention provides a technical solution: a highway bridge prestressing stroke, including the body 1, both sides of the bottom end of the body 1, and the roller 2, the outer wall of the body 1 is provided with a lifting device 3, a lifting device. 3 includes a threaded rod 301, a thick plate 302, a circular plate 303, a first frame 304, a first spring 305, a vertical rod 306, and a groove 307, and the outer wall of the threaded rod 301 is connected to the top of the body 1, the threaded rod 301 The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com