Scraper knife posture control system and method based on machine vision and land leveler

A posture control and machine vision technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. Work quality is difficult to guarantee and other problems, to achieve the effect of solving the collision problem, improving the safety of work, reducing the difficulty of manipulation and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

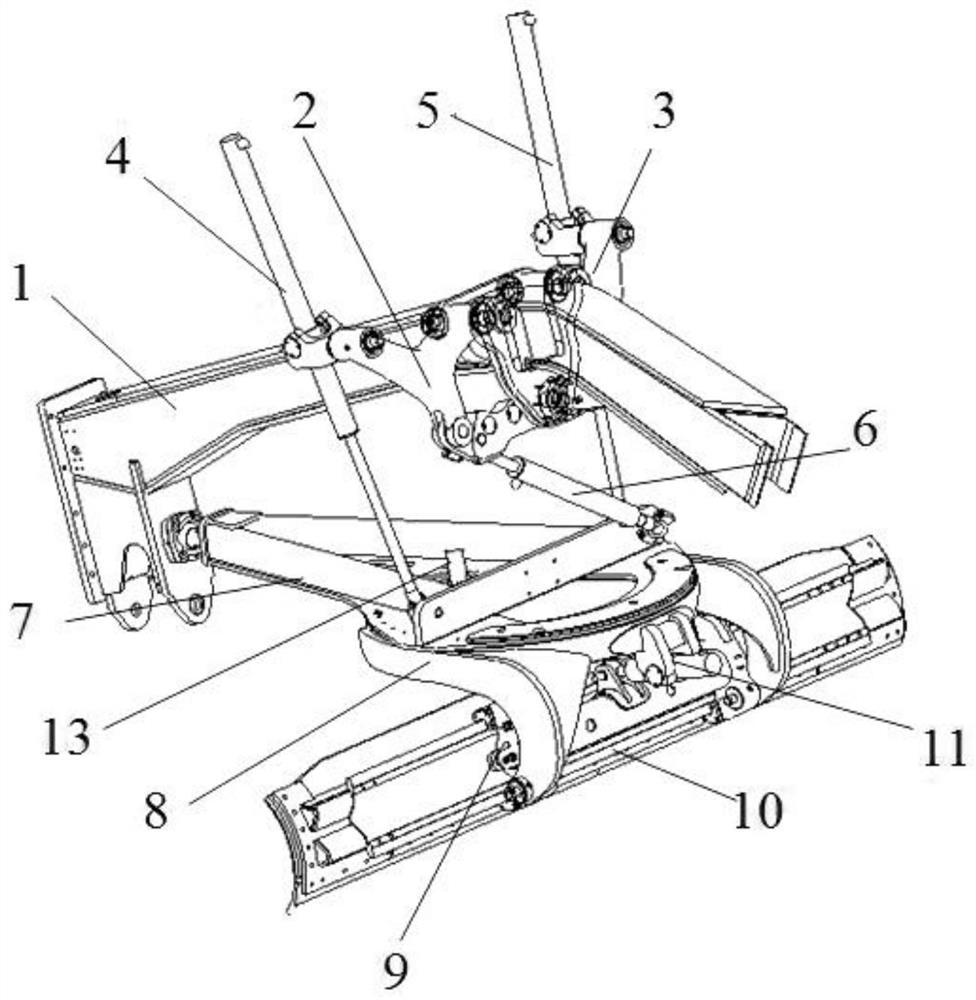

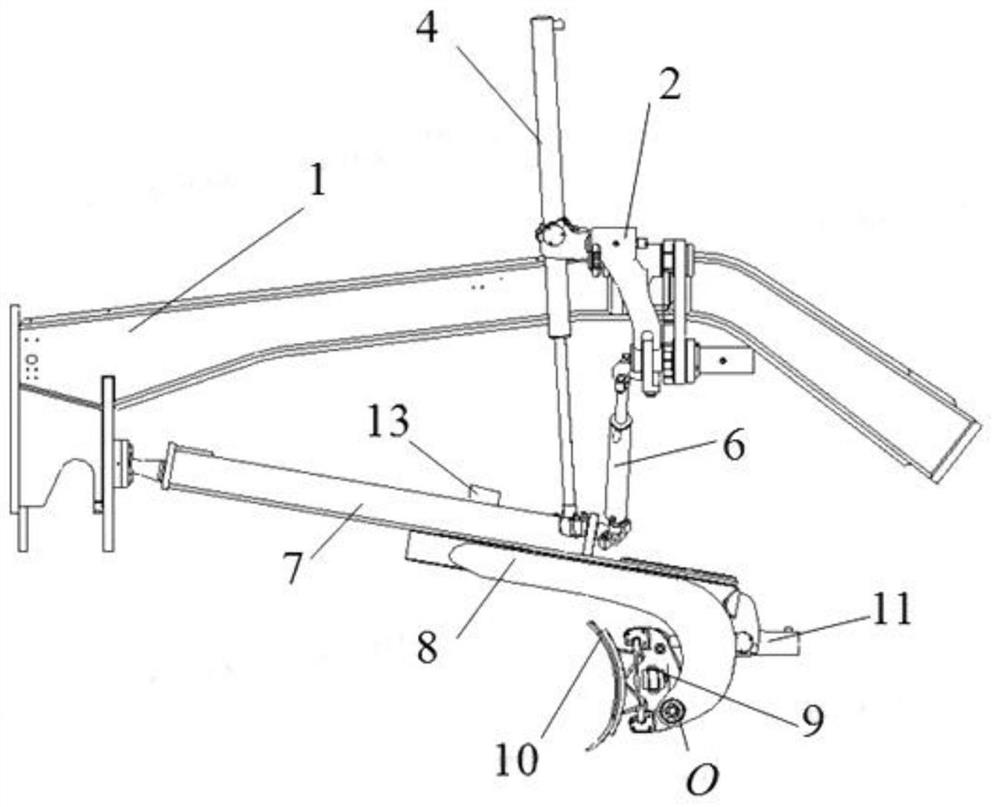

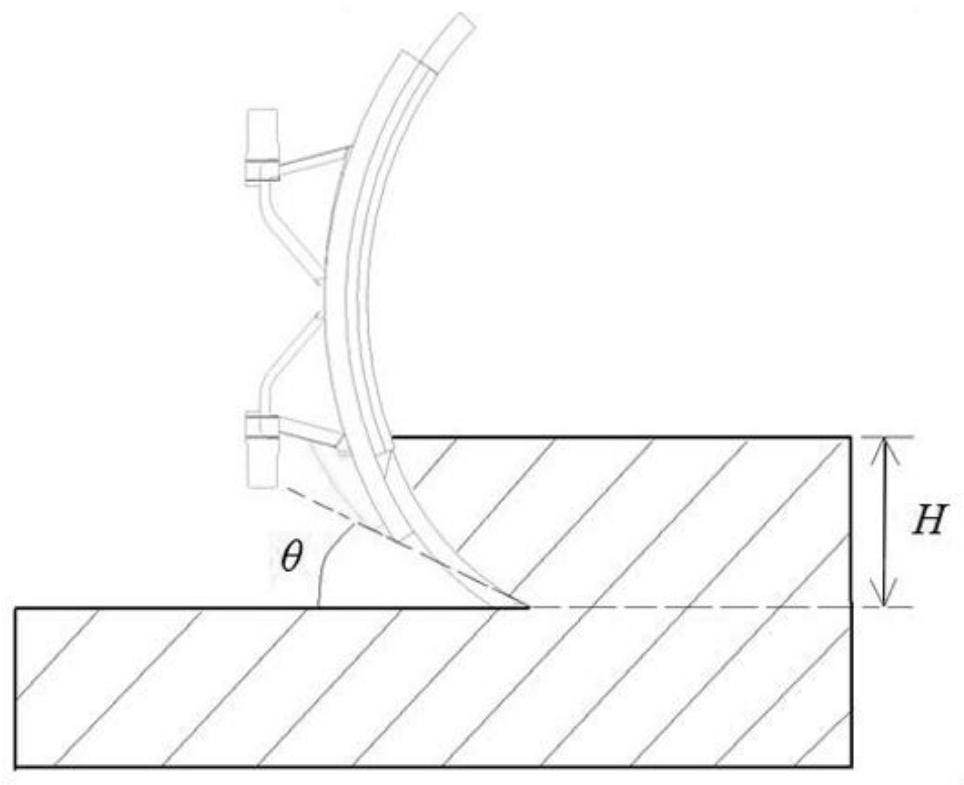

[0029] Such as Figure 1~Figure 10 As shown, a blade attitude control system based on machine vision includes: several cameras 15 installed at the set position of the grader for collecting multiple visual perception tracking points 16 installed at the set position of the grader The real-time position information and send to the vision processing unit 17; The target attitude of the blade 10 generates the target state of the blade attitude control mechanism, and sends the target state and the current state of the blade attitude control mechanism to the on-board controller 18; the on-board controller 18 is used to The target state and current state of the control mechanism are controlled, and the blade attitude control mechanism is controlled through the electric proportional control valve 20, so that the blade attitude control mechanism drives the blade 10 to the target attitude.

[0030] Such as figure 1 , 2 , 7, and 8, in the present embodiment, the blade attitude control m...

Embodiment 2

[0038] Based on the blade attitude control system based on machine vision described in Embodiment 1, this embodiment provides a motor grader configured with the blade attitude control system based on machine vision described in Embodiment 1.

Embodiment 3

[0040] Based on the blade attitude control system based on machine vision described in Embodiment 1, this embodiment provides a blade attitude control method based on machine vision, including:

[0041] 1) Collect real-time position information of multiple visual perception tracking points installed at the set position of the grader;

[0042] 2) Obtain the current posture of the blade according to the real-time position information of each visual perception tracking point, and combine the target posture of the blade to generate the target state of the blade posture control mechanism;

[0043] 3) According to the target state and current state of the blade attitude control mechanism, the blade attitude control mechanism is controlled through the electric proportional control valve, so that the blade attitude control mechanism drives the blade to the target attitude, specifically:

[0044] 31) According to the target state and current state of the blade attitude control mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com