100MW subcritical single-cylinder single-exhaust steam turbine

A subcritical and steam turbine technology, applied in the direction of steam engine devices, mechanical equipment, engine components, etc., can solve the problems of low unit cycle efficiency, unreasonable design, poor overall performance, etc., to shorten the length of shafting, shorten the length of the unit, The effect of high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

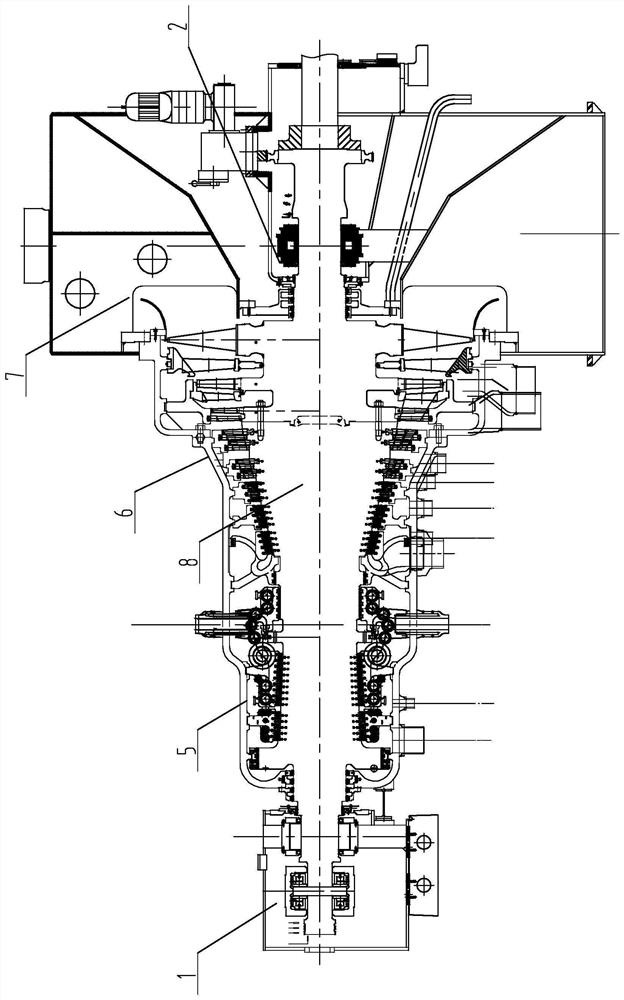

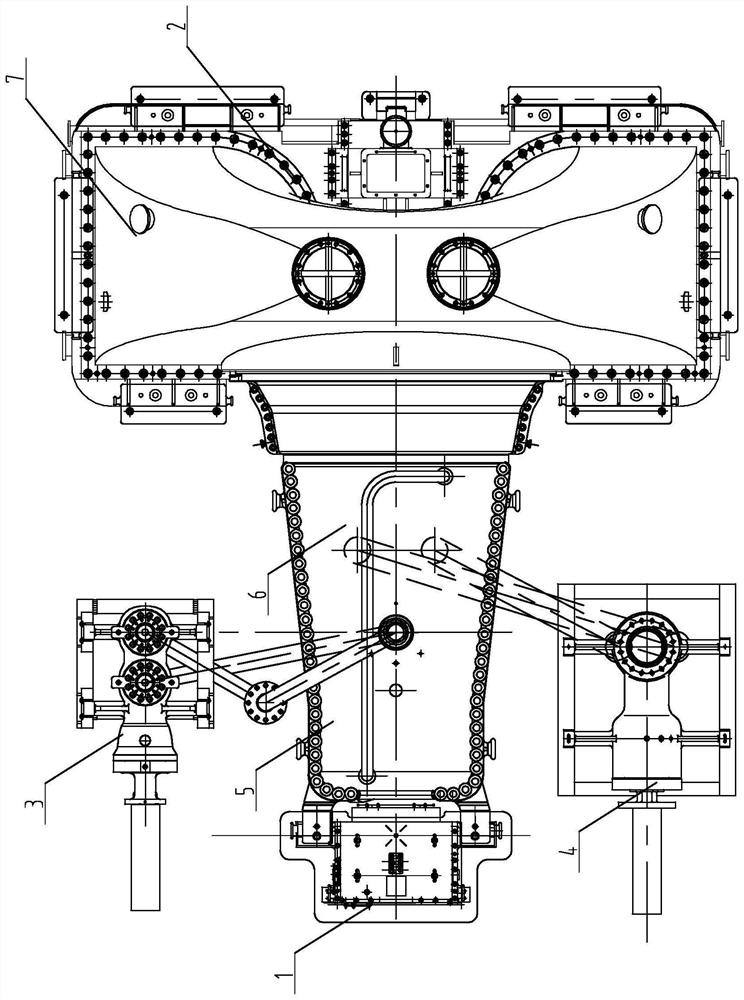

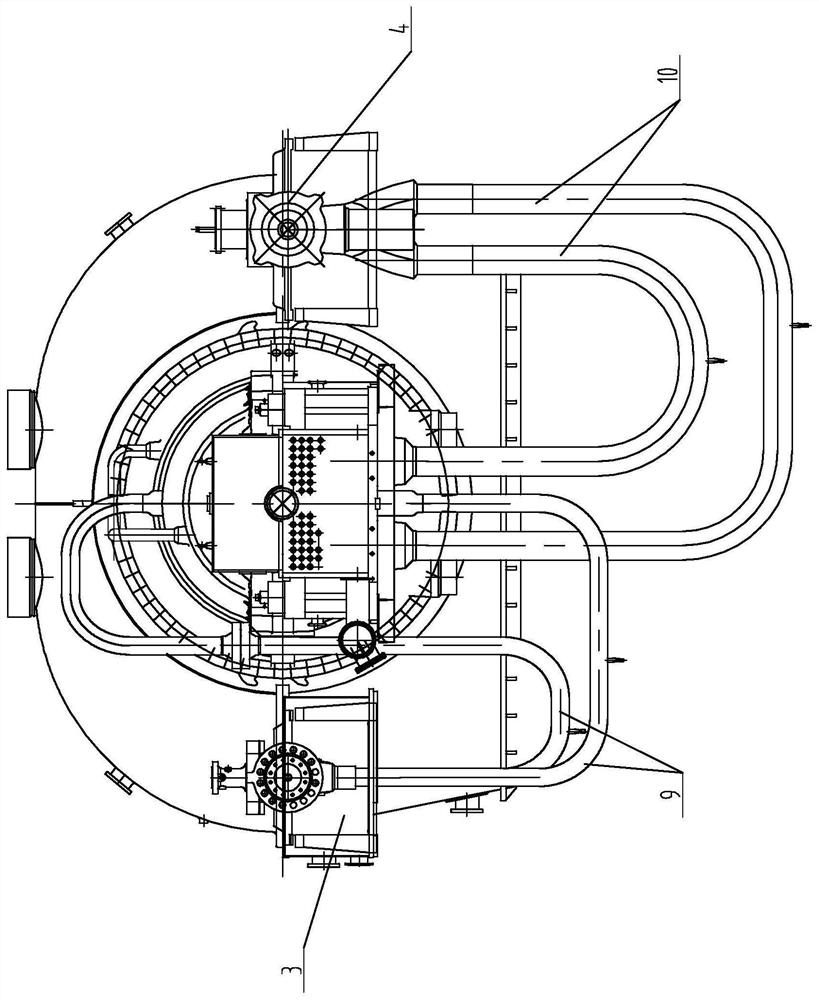

[0014] Specific implementation mode one: refer to Figure 1 to Figure 3 Describe this embodiment. This embodiment provides a 100MW subcritical single-cylinder single-exhaust steam turbine, which includes a front bearing box 1, a rear bearing box 2, a high-pressure main steam regulating valve 3, and a medium-pressure reheat regulating valve 4. , high-pressure cylinder 5, medium-low pressure cylinder 6, low-pressure exhaust steam cylinder 7 and rotor 8 as a whole; high-pressure cylinder 5, medium-low pressure cylinder 6 and low-pressure exhaust cylinder 7 are fixedly connected in sequence, and the front bearing housing 1 is set close to the high-pressure cylinder 5 , the rear bearing housing 2 is set close to the low-pressure exhaust steam cylinder 7, and the rotor 8 is arranged in the front bearing housing 1, the high-pressure cylinder 5, the medium-low pressure cylinder 6, the low-pressure exhaust steam cylinder 7 and the rear bearing housing 2 in turn, and the high-pressure ma...

specific Embodiment approach 2

[0015] Specific implementation mode two: refer to Figure 1 to Figure 3 Describe this embodiment. This embodiment provides a 100MW subcritical single-cylinder single-exhaust steam turbine. The overall rotor 8 includes a high-temperature zone rotor, a low-temperature zone rotor, and a plurality of rotor connecting bolts. The high-temperature zone rotor and the low-temperature zone rotor are along a straight line. Coaxial arrangement, one end of the rotor in the high temperature zone and one end of the rotor in the low temperature zone are fixedly connected by a plurality of rotor connecting bolts. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Specific implementation mode three: refer to Figure 1 to Figure 3 Describe this embodiment. This embodiment provides a 100MW subcritical single-cylinder single-exhaust steam turbine. The front bearing box 1 and the rear bearing box 2 are both placed on the ground, and the connection between the front bearing box 1 and the rotor 8 is provided with a separate dead point. .

[0017] Ensure that the low-pressure end steam seal and the rotor gap installed on it will not be affected by the deformation and temperature of the low-pressure cylinder. The two sections before and after have different mechanical properties, which not only meet the high temperature strength requirements of the high temperature section, but also meet the high strength and low brittle transition temperature performance of the low temperature section. Other compositions and connection methods are the same as those in Embodiment 1.

[0018] In this embodiment, in the high-pressure main steam regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com