Carbon combustion-controllable heating furnace

A technology for heating stoves and charcoal strips, which is applied in the combustion air/flue gas circulation of furnaces, household stoves/stoves, solid heating fuels, etc., and can solve problems such as short combustion time and uneven combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

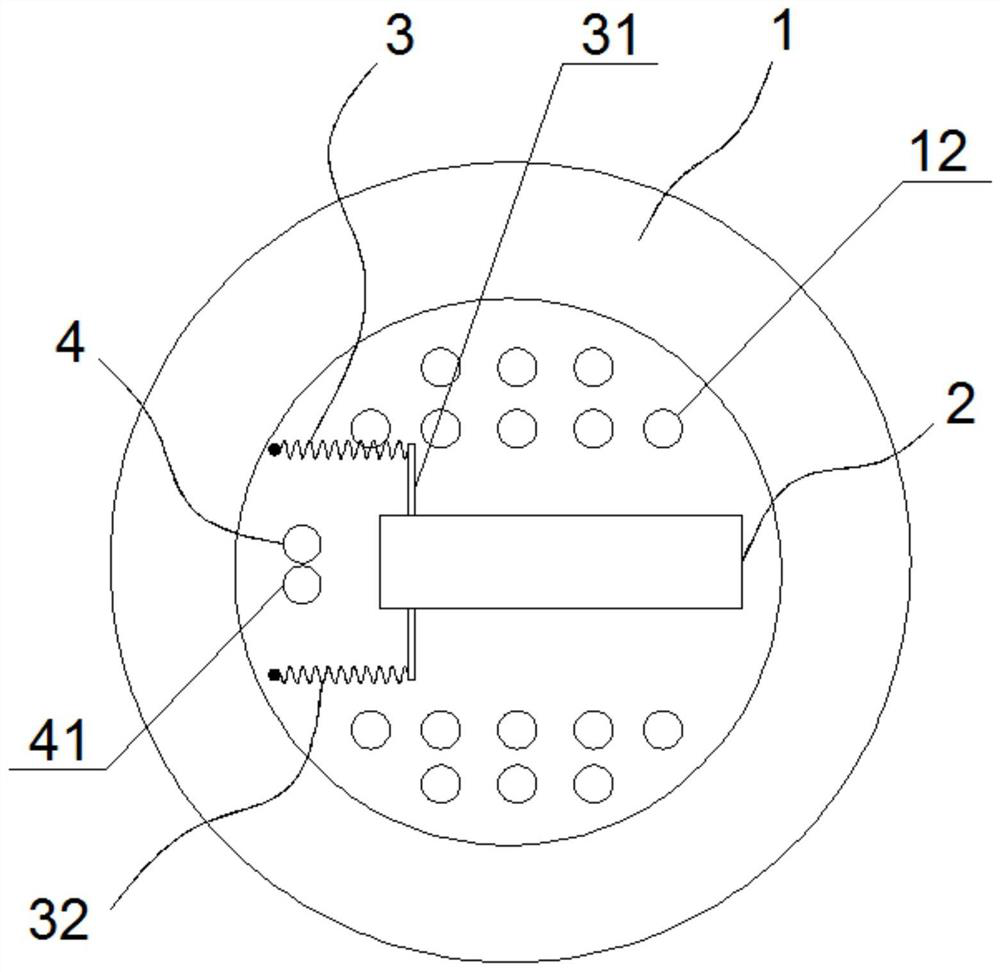

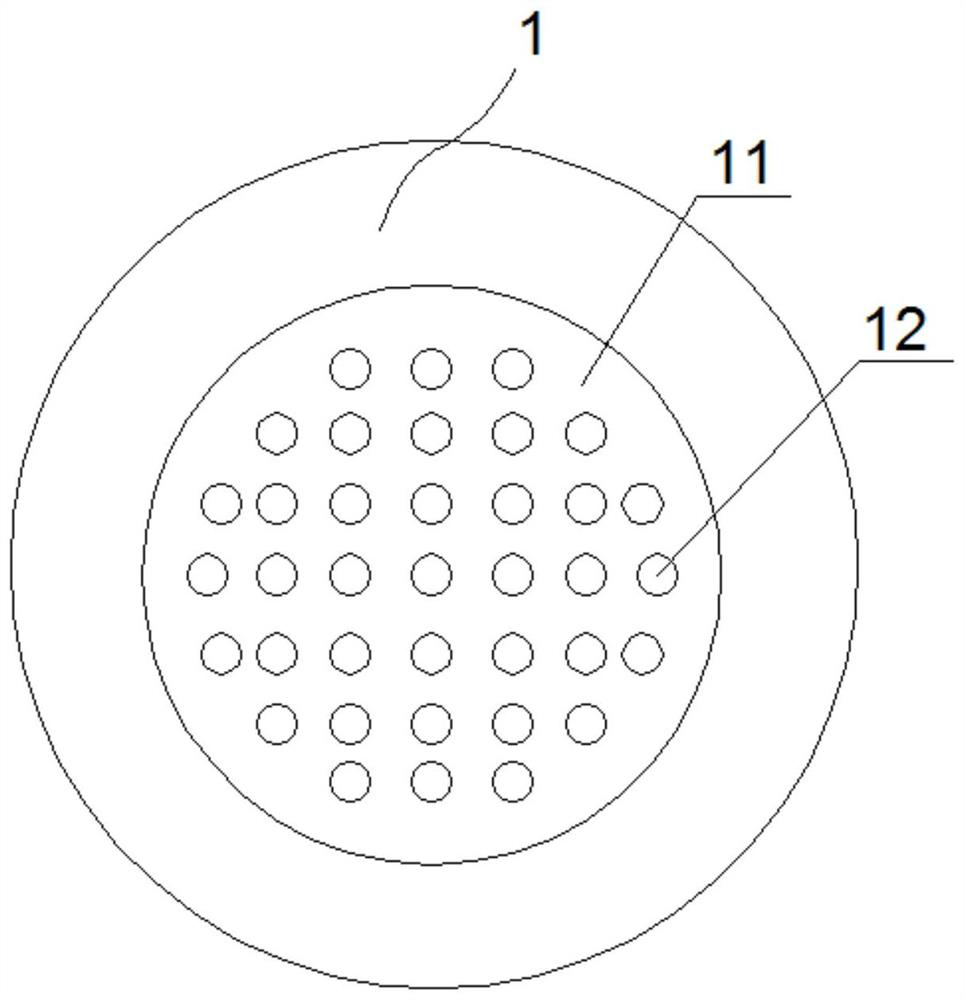

[0026] Such as Figure 1 to Figure 5 As shown, the present invention is a heating furnace with controllable combustion of charcoal, comprising: a shell 1 with a cover, the shell 1 is a hollow cavity, and a hole for connecting the inside and outside of the shell 1 is opened on the shell 1 The ventilation hole 12 is used to provide the carbon rod 5 with the oxygen required for combustion, and at the same time take out the heat of the carbon rod 5 after burning.

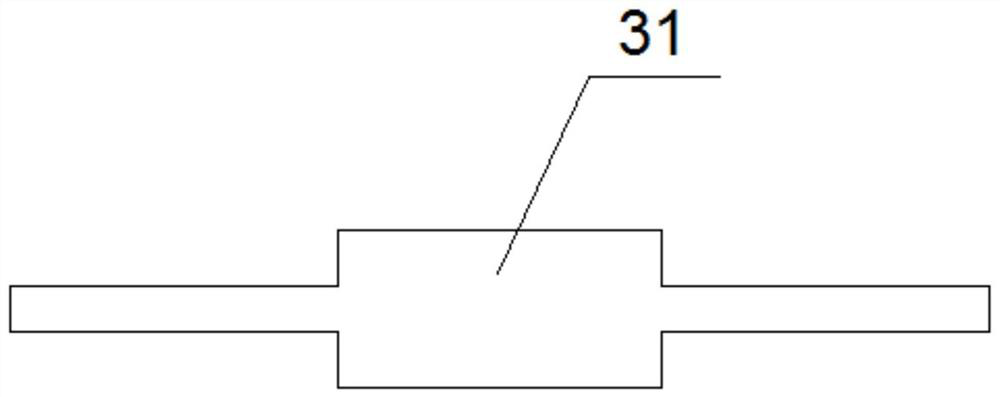

[0027] A carbon rod sleeve 2 for placing carbon rods 5 is fixed on the inner wall of the housing 1. The carbon rod sleeve 2 is rectangular as a whole, and it includes a carbon rod installation groove 21 and a carbon rod installation groove 21 that is detachably installed on the carbon rod sleeve 2. Loam cake 22, and one end of carbon rod installation groove 21 is charcoal outlet, on the upper wall and lower wall of carbon rod installation groove 21, all offer chute 23 along the length direction of carbon rod installatio...

Embodiment 2

[0031] The difference between Embodiment 2 and Embodiment 1 lies in the structure of the carbon rod sleeve 2 and the automatic reset device 32 .

[0032] Such as Figure 6 As shown, the carbon rod sleeve 2 is arc-shaped, and the fixing bolt 41 is arranged at the carbon outlet of the carbon rod sleeve 2 . The automatic reset device 32 is a group, which is arranged on the inner side of the arc of the carbon rod sleeve 2. The spring 322 is a constant force spring. One end of the spring 322 is fixed on the housing 1 through a positioning piece 321, and the other end is connected to the pusher. The plate 31 is connected, and the carbon strip 5 drives the push plate 31 to slide in the carbon strip sleeve 2 through the spring 322 .

Embodiment 3

[0034] Embodiment 3 differs from Embodiment 1 and Embodiment 2 only in that the positions of the carbon rod sleeve 2 and the power mechanism 3 are different.

[0035] Such as Figure 7 As shown, the carbon rod sleeve 2 is rectangular, the power mechanism 3 is located in the carbon rod sleeve 2, the power mechanism 3 includes a push plate 31 and an automatic reset device 32, and the automatic reset device 32 includes a positioning member 321 and at least one set of springs 322, the positioning part 321 is arranged on the inner bottom of the carbon rod sleeve 2, and the spring 322 is an extension spring, and one end of the spring 322 is fixed on the carbon rod sleeve 2 through the positioning part 321, and the other end is connected with the push plate 31 connected, the carbon strip 5 drives the push plate 31 to slide in the carbon strip sleeve 2 through the spring 322 .

[0036] work process:

[0037] Before use, first ignite one end of the carbon rod 5, then put the carbon r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com