Method for testing interfacial strength of textile fabric fibers

A technology of interface strength and test method, applied in the field of textile fabrics, can solve the problems of difficulty in testing multiple monofilaments at the same time, affecting the measurement results, and low test efficiency, and achieves the effects of good fixation effect, good contrast effect and high test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

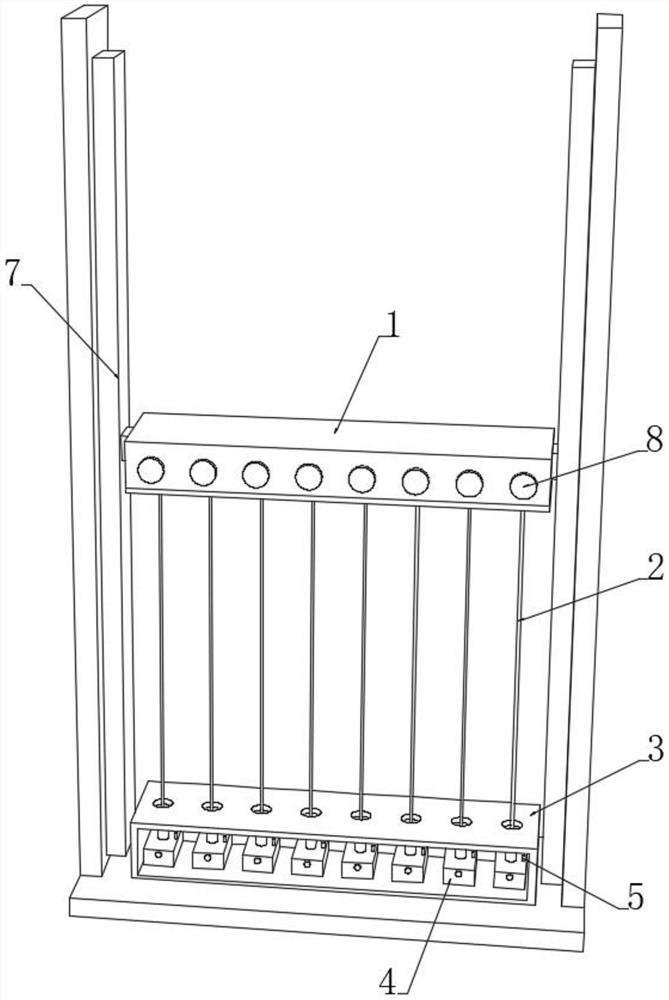

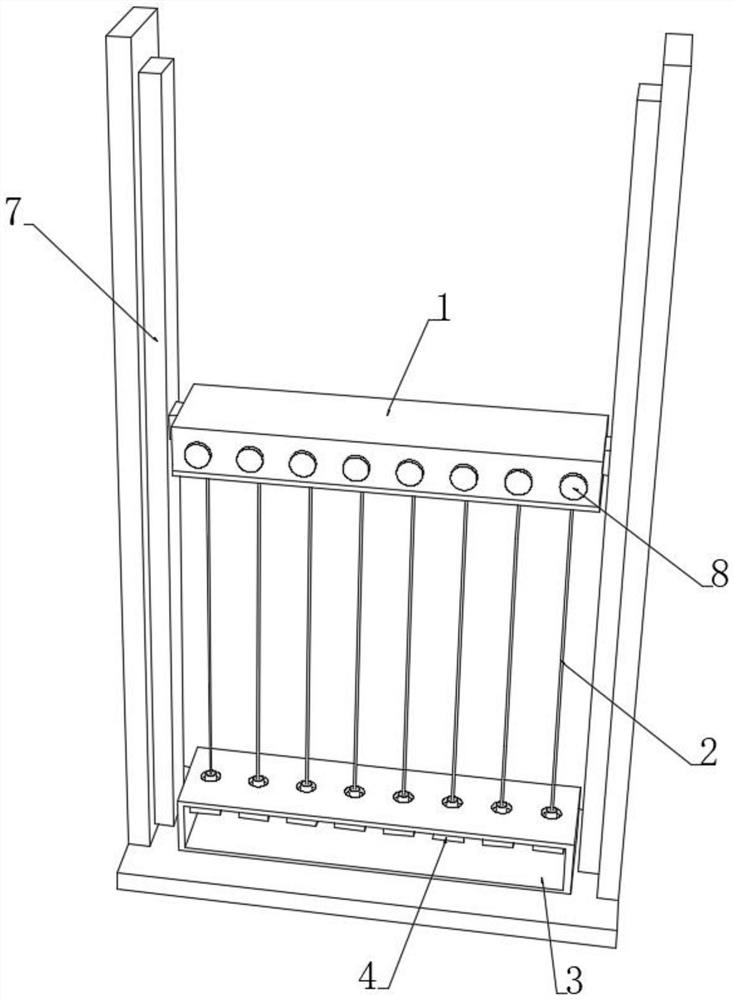

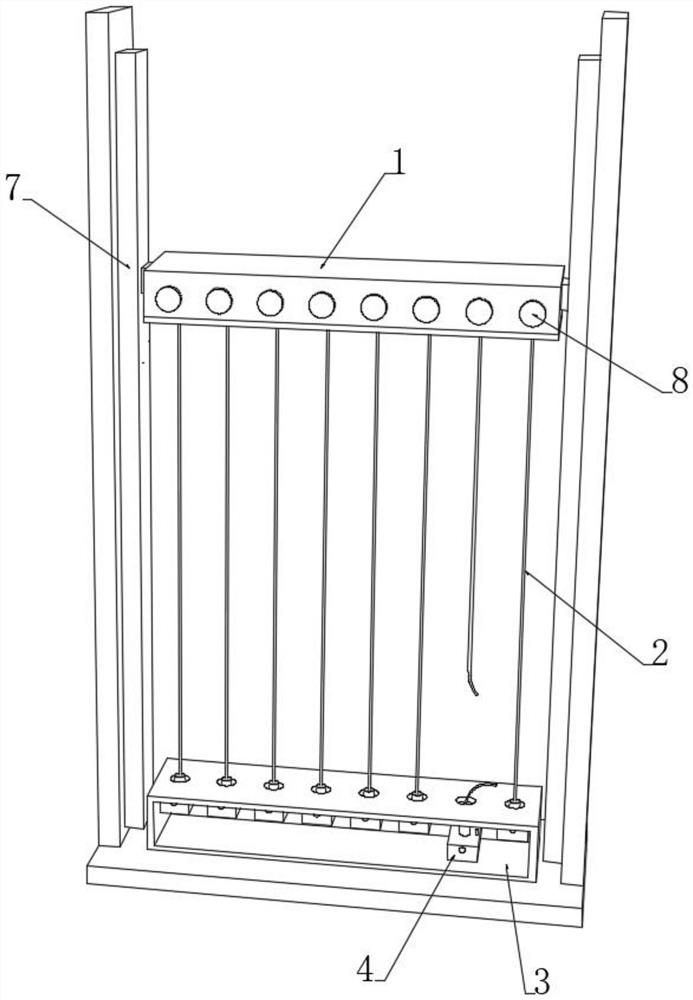

[0050] see Figure 1-7 , a kind of interfacial strength testing method of textile fiber, comprises the following steps:

[0051] S1. Prepare the upper sealant 1 that encapsulates multiple fibers 2, prepare the upper hollow glue injection box 101 and the sealing plate 102, insert multiple fibers 2 into the fibers 2 at equal intervals, and inject the upper hollow glue injection box 101 upwards Fixing glue 103, after the upper fixing glue 103 is solidified, the outer ends of the plurality of fibers 2 are penetrated through the sealing plate 102 and extended outward;

[0052] S2. Prepare a plurality of lower sealing colloids 4 corresponding to the number of fibers 2. The lower sealing colloids 4 include a lower hollow glue injection box 401 and a glue injection nozzle 402 arranged on one side of the lower hollow glue injection box 401;

[0053] S3. Prepare the work table, install vertical electric slide rails 7 on both sides of the upper end of the work table, and install the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com