Inherent frequency tester for impurities in fluid medium

A technology of natural frequency and fluid medium, which is applied in the field of natural frequency tester, and can solve problems such as the decrease of the test effect of the vibration sensor on the fluid, the tilt of the vibration sensor, and the position shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

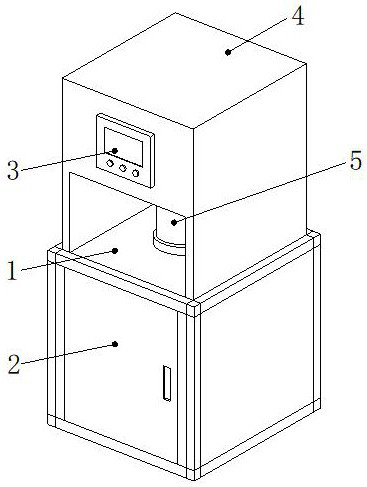

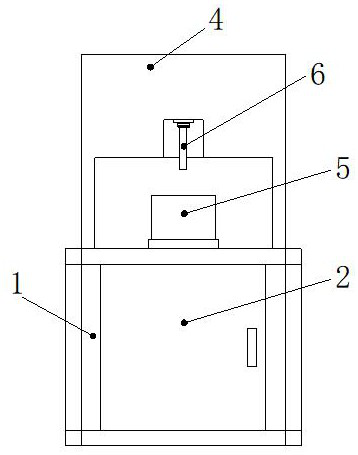

[0023] as attached figure 1 To attach Figure 6 Shown:

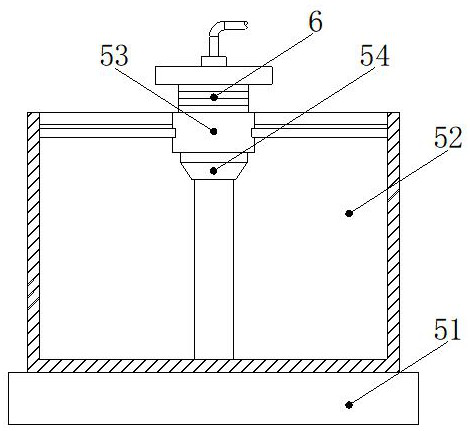

[0024] The present invention is a natural frequency tester for impurities in a fluid medium. Its structure includes a support platform 1, a box door 2, a display panel 3, a testing machine 4, a storage device 5, and a vibration sensor 6. The front of the support platform 1 The surface is provided with a box door 2, and the top of the support platform 1 is welded to the bottom of the testing machine 4, the display panel 3 is embedded in the front surface of the testing machine 4 and electrically connected, and the middle part of the upper surface of the support platform 1 is provided with a holding device 5 , the vibration measuring sensor 6 is installed in the middle end of the testing machine 4, and the vibration measuring sensor 6 is located directly above the holding device 5, and the holding device 5 includes a base 51, a holding tank 52, a supporting device 53, a scraper In addition to the device 54, the base 51 i...

Embodiment 2

[0031] as attached Figure 7 To attach Figure 8 Shown:

[0032] Wherein, the scraping device 54 includes an outer frame 541, a rejecting mechanism 542, and a lower guide groove 543. The upper end of the outer frame 541 is welded to the lower end of the supporting outer ring 34a, and the inner wall of the lower end of the outer frame 541 is connected to the lower end of the rejecting mechanism 542. fixed, and the inner wall of the lower end of the outer frame 541 is embedded with a lower guide groove 543, the outer frame 541 is a hollow conical structure with a wide top and a narrow bottom, ensuring that the vibration sensor 6 can be normally lowered inside the outer frame 541, while the vibration sensor 6. During the upward movement, the fluid that reduces the adhesion on the outside of the vibration measuring sensor 6 is brought into the outer frame 541. There are twelve lower guide grooves 543, which are distributed on the inner wall of the lower end of the outer frame 541...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com