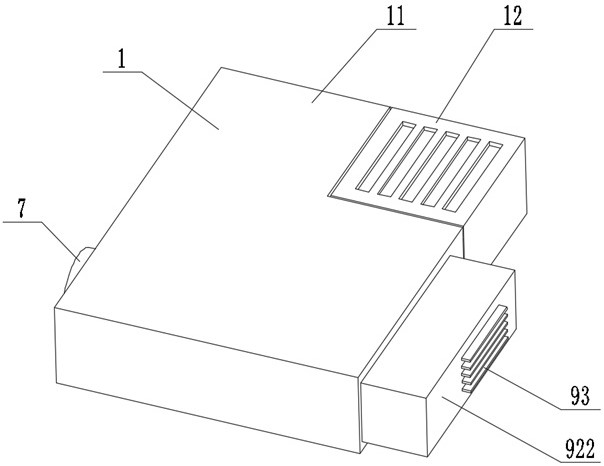

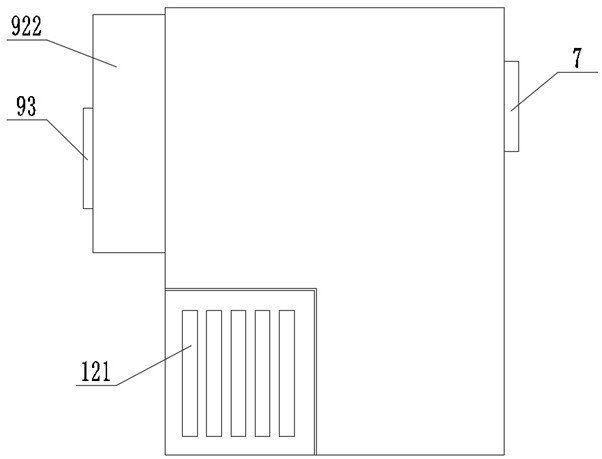

dlp projection device

A projection device and lens technology, applied in projection devices, instruments, optics, etc., can solve the problems of high temperature of the projector, easy dust pollution, etc., reduce the difficulty of heat dissipation, avoid pollution or damage, improve projection effect and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

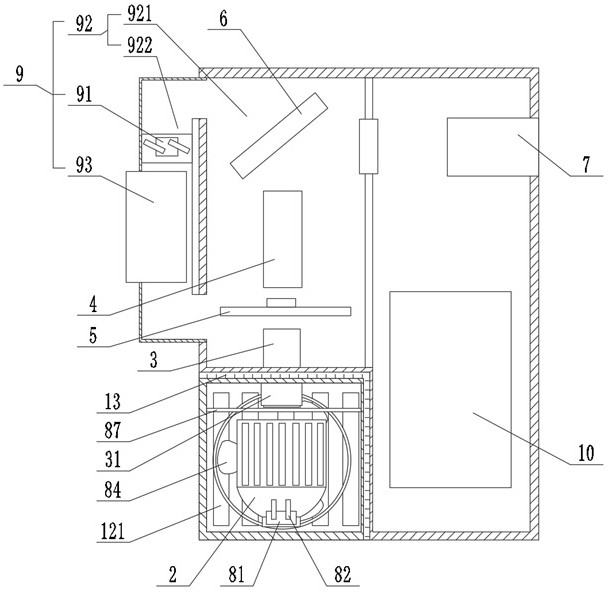

[0040] The second radiator 9 drives the air in the sealed chamber 11 to circulate, and dissipates the heat in the sealed chamber 11 through the fins 93 penetrating through the sealed chamber 11 . Such as image 3 As shown, according to an embodiment of the present invention, the second radiator 9 includes a circulation fan 91, a circulation flow channel 92 and a cooling fin 93, and the circulation flow channel 92 includes a first flow channel 921 and a second flow channel that communicate with each other. The flow channel 922, the first flow channel 921 is located in the sealed cavity 11, the optical path assembly is arranged in the first flow channel 921, the second flow channel 922 is located outside the sealed cavity 11, and the circulation The fan 91 is disposed in the second flow channel 922 , one end of the cooling fin 93 is disposed in the second flow channel 922 , and the other end is disposed outside the second flow channel 922 . By setting the circulation channel 92...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com