A Characteristic Correction Method of Multistage Axial Compressor Based on One-dimensional Mean Streamline Method

A correction method and a streamline method technology, applied in the field of simulation, can solve problems such as complex flow conditions, and achieve the effects of fast calculation speed, improved accuracy, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

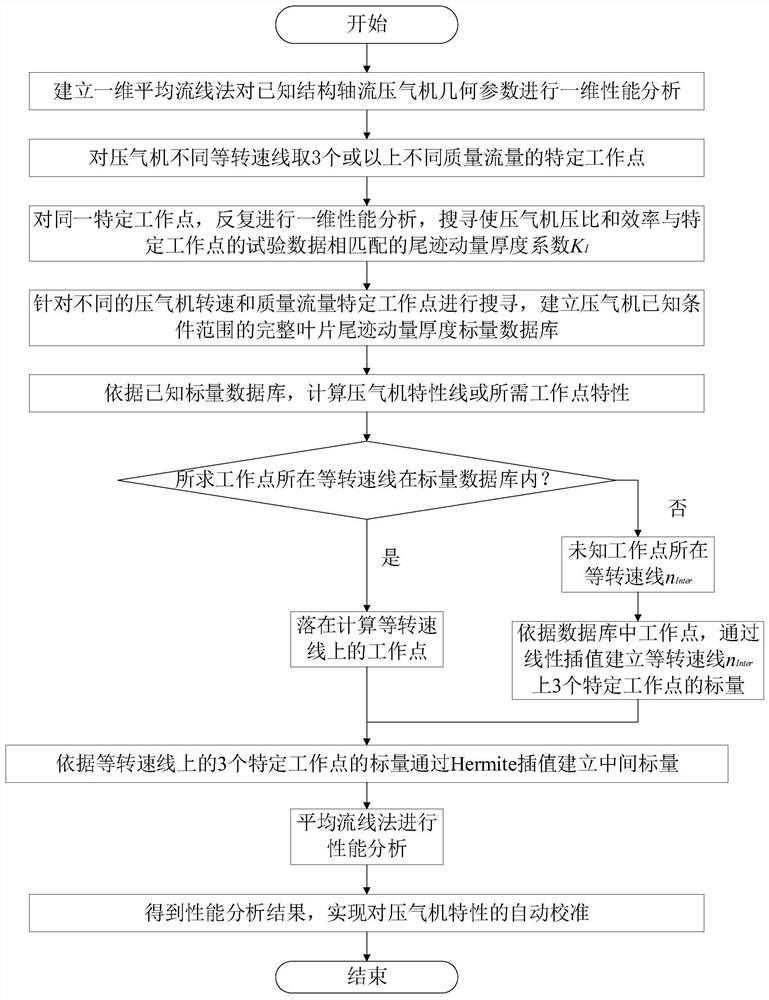

[0030] The present invention is described in more detail below in conjunction with accompanying drawing example:

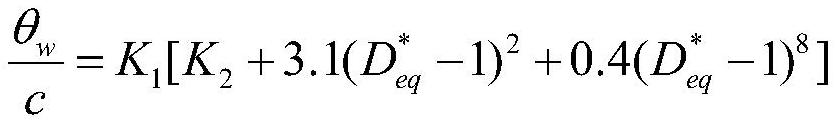

[0031] combine figure 1 , taking the intersection of the average streamline and the front and rear edges of each row of blades as the calculation point of the flow field parameters, the flow parameters at the positions of each calculation station represent the overall aerodynamic layout of the compressor, and the empirical models such as lagging angle and loss reflect the viscous Influenced by factors such as turbulence, turbulence, trans-sound, unsteady and other factors, the outlet parameters of blades at all levels (rows) are calculated along the axial direction, so as to advance the calculation, and finally the overall performance and aerodynamic layout parameters of the whole machine are obtained through superposition. An aerodynamic analysis method for multi-stage axial flow compressors based on the one-dimensional mean streamline method is established. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com