Method and system for automatically monitoring inspection standardization of premixed concrete production raw materials

A technology of ready-mixed concrete and automatic monitoring, applied in the field of material inspection, can solve problems such as weak sense of responsibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

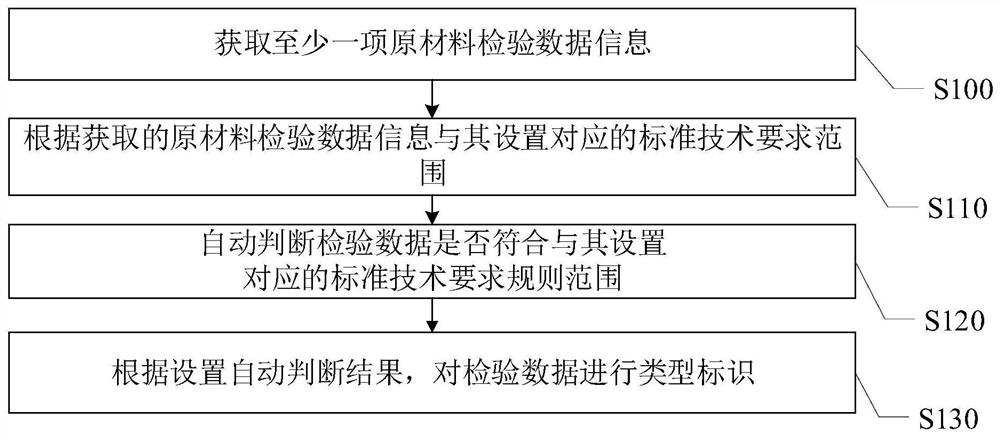

[0035] see figure 1 , figure 1 Shown is a schematic diagram of the steps of a standardized automatic monitoring method for the inspection of raw materials for ready-mixed concrete production provided by the embodiment of the present application, which is as follows:

[0036] Step S100, obtaining at least one piece of raw material inspection data information;

[0037] In some embodiments, raw materials may include cement, mineral powder, sand, stone, admixtures, fly ash, admixtures, and the like.

[0038] Step S110, according to the obtained raw material inspection data information and setting corresponding standard technical requirement range;

[0039] In some embodiments, the standard requirements also include GB175 "General Portland Cement"; GB / T2419 "Method for Determination of Fluidity of Cement Mortar Sand"; GB / T208 "Method for Determination of Cement Density"; GB / T1346 "Standard Consistency of Cement" Water consumption, setting time, stability test method"; GB / T8074 "Ce...

Embodiment 2

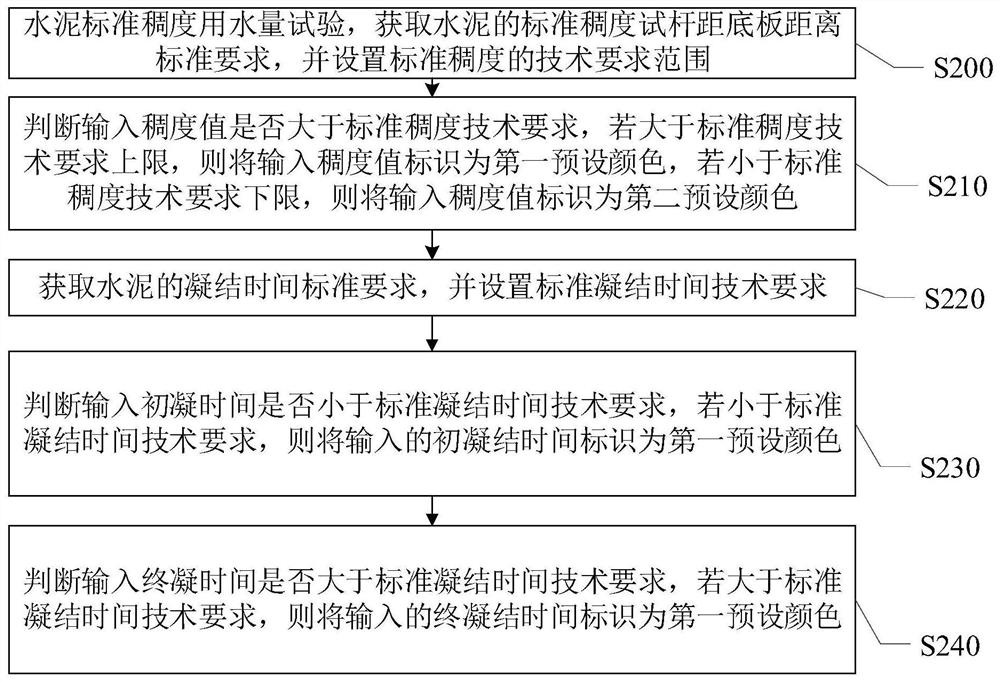

[0045] see figure 2 , figure 2 A schematic diagram of the detailed steps of a standardized automatic monitoring method for the inspection of raw materials for ready-mixed concrete production provided by the embodiment of the present invention is as follows:

[0046] Step S200 , water consumption test for standard consistency of cement, obtaining the standard requirement for the distance between the test rod and the base plate for the standard consistency of cement, and setting the technical requirement range for the standard consistency.

[0047] Step S210, judging whether the input consistency value is greater than the standard consistency technical requirement, if greater than the standard consistency technical requirement upper limit, then mark the input consistency value as the first preset color, if less than the standard consistency technical requirement lower limit, then the input consistency value is marked as Second default color.

[0048] Step S220, obtaining sta...

Embodiment 3

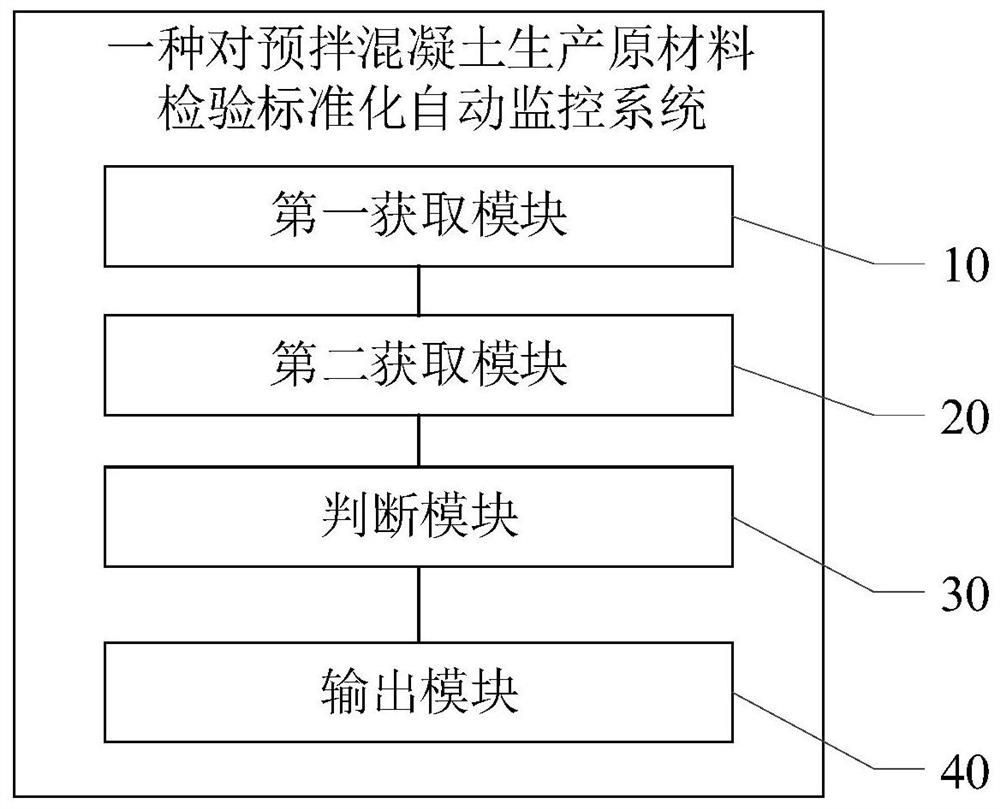

[0068] see image 3 , image 3 A schematic diagram of a standardized automatic monitoring system module for the inspection of raw materials for ready-mixed concrete production provided by the embodiment of the present invention is as follows:

[0069] The first acquisition module 10 is used to acquire at least one piece of raw material inspection data information;

[0070] The second acquisition module 20 is used to set the corresponding standard technical requirement range according to the acquired raw material inspection data information;

[0071] Judgment module 30, used to judge whether the inspection data meets the scope of corresponding standard technical requirements;

[0072] The output module 40 is configured to identify the type of the inspection data according to the automatic judgment result.

[0073] It also includes a memory, a processor and a communication interface, the memory, the processor and the communication interface are electrically connected to each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com