Method for improving 850nm semiconductor laser power density

A laser power and semiconductor technology, which is applied in the direction of semiconductor lasers, semiconductor laser devices, semiconductor laser optical devices, etc., can solve the problems of high-power semiconductor lasers with large light divergence angles and poor light quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

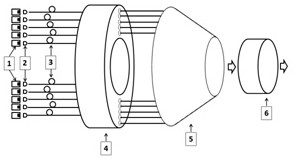

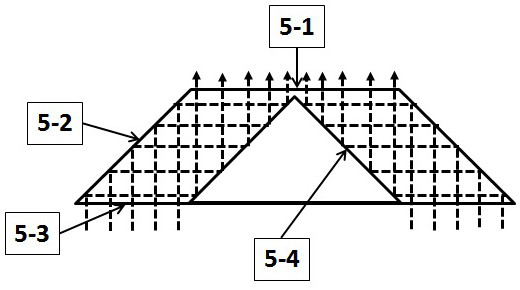

[0014] Combine below figure 1 and figure 2 The present invention is further described in detail.

[0015] The invention discloses a method for increasing the power density of an 850nm semiconductor laser, which includes an 850nm semiconductor laser single-tube module (1), a collimating mirror (2), an optical fiber (3), a ring holder (4), and a hollow trapezoidal round table ( 5) and focusing mirror (6). The hollow trapezoidal round platform (5) comprises the upper bottom surface of the round platform (5-1), the outer side of the round platform (5-2), the lower bottom surface of the round platform (5-3) and the inner side of the round platform (5-4).

[0016] figure 1 Take ten 850nm semiconductor laser single-tube modules in a single direction as an example for specific description. Each 850nm semiconductor laser single-tube module of ten 850nm semiconductor laser single-tube modules (1) is coupled into an optical fiber (3) through a collimator (2), and the optical fiber (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com