Laser light source module and projection display system

A laser light source and module technology, applied in optics, instruments, projection devices, etc., can solve the problems of large spot gap, large overall volume, and energy loss of laser light source, achieve high laser power density, small size, and avoid energy loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

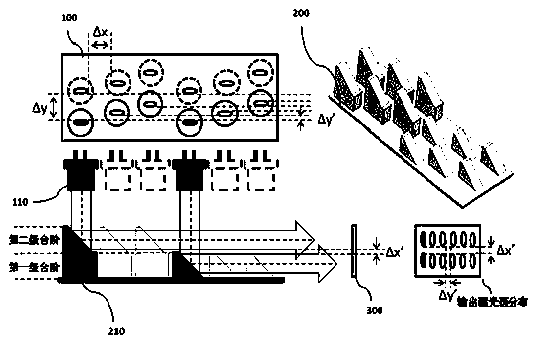

[0037] Such as figure 1 As shown in , in this embodiment, all semiconductor lasers are packaged on the same heat dissipation substrate, and the semiconductor laser arrays 100 are arranged in three groups, and every four semiconductor lasers 110 is a group. Since the collimating mirror does not have a directional cover for the laser beam emitted by the semiconductor laser 110 , the spot distribution after being collimated by the collimating mirror can be regarded as the distribution of the semiconductor laser 110 . Therefore from figure 1 It can be seen from the distribution of the elliptical spot after the semiconductor laser 110 is collimated by the collimating mirror (not shown in the figure) that figure 1 It can be seen that the row spacing Δx (the distance between two adjacent semiconductor lasers 110 ) and the column spacing Δy (the gap between two adjacent elliptical spots in the short axis direction) of the spots of the original laser light source are relatively large,...

Embodiment 2

[0043] Such as figure 2 As shown, in this embodiment, the semiconductor laser array 100 is arranged into 2 large groups, and each large group is divided into 3 small groups, and there are 2 semiconductor lasers 110 in each small group, so in this embodiment, there are 12 semiconductor laser arrays 100 . In the semiconductor laser array in this embodiment, the large groups are arranged sequentially along the long axis direction of the elliptical light spot after the semiconductor lasers are collimated by the collimating mirror, and there is no dislocation arrangement. And between the groups with a certain interval Δy , Misalignment settings, such as figure 2 shown in .

[0044] Correspondingly, the stepped reflector array 200 is also set into 2 groups, and each group is divided into 3 groups, with 12 stepped reflectors 210, and each stepped reflector 210 has only one step (reflecting surface ), so that the stepped reflector 210 corresponds to the semiconductor laser 110 o...

Embodiment 3

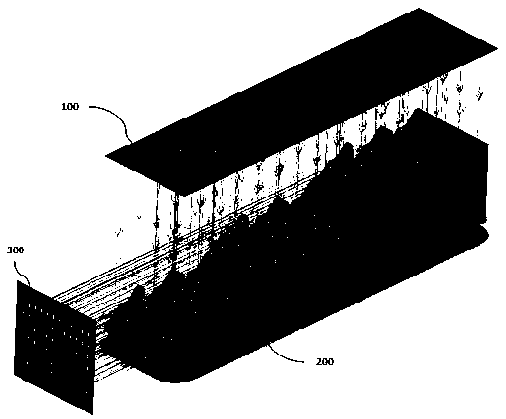

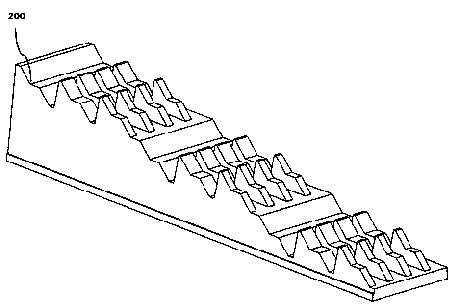

[0047] Such as Figure 3-5 As shown, in this embodiment, the semiconductor laser array 100 is arranged into 3 large groups, and each large group is divided into 3 small groups, and each group is provided with 8 semiconductor lasers 110, so in this embodiment, a total of Seventy-two semiconductor lasers 110 are provided. from Figure 5 It can be seen from the figure that in the semiconductor laser array 100 in this embodiment, the large groups are arranged sequentially along the long axis direction of the elliptical spot after the semiconductor laser is collimated by the collimating mirror, and there is no misalignment. And between the groups with a certain interval Δy , Misplaced settings.

[0048] Correspondingly, the stepped reflector array 200 in this embodiment is also provided with 3 large groups, and each large group is further divided into 3 subgroups, and each subgroup is provided with 4 stepped reflector arrays 210 . Since all the stepped reflectors 210 in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com