A control method of placement machine using hierarchical state machine

A control method and state machine technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of high time and cost, the control program is difficult to be applied and the state requires the control system, etc., and achieves the effect of good robustness, simple coding and clear logic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

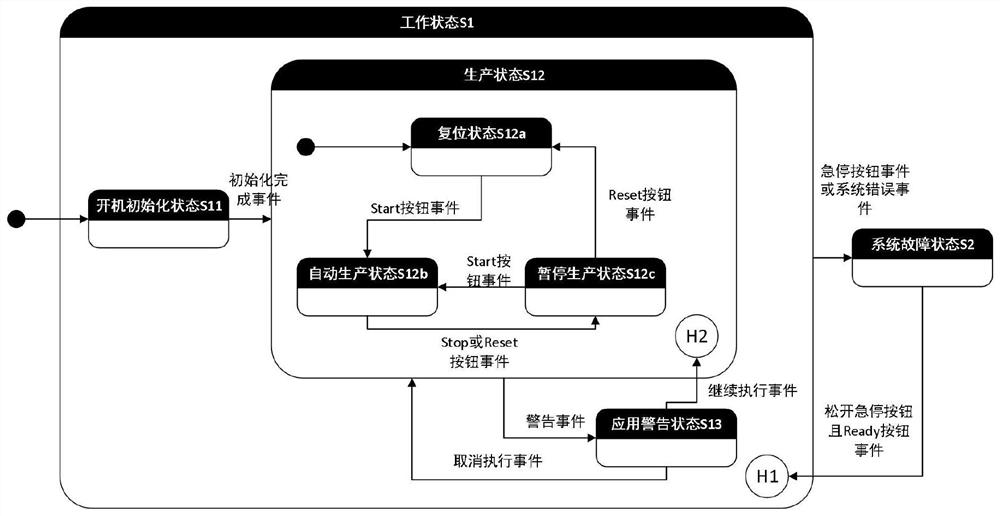

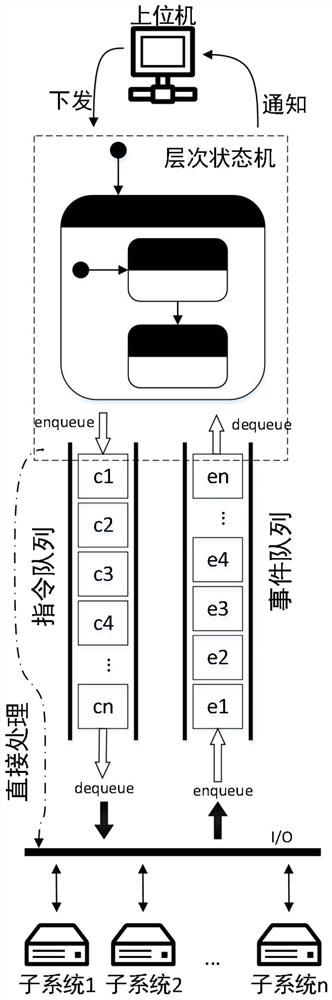

[0051] In this embodiment, a placement machine control method using a hierarchical state machine is applied to a production environment composed of a host computer, a hierarchical state machine, and a placement machine. First, the placement work of the placement machine is summarized Analysis, decomposing the working state of the placement machine into multiple sub-states in the hierarchical state machine, linking the different sub-states of the placement machine through event-driven transfer, and then using the command event scheduler to manage the command and event queue scheduling. On the one hand The information that the subsystem interacts with is encapsulated as an event for transmission, and the sub-state is converted through the different sub-states of the state module box after receiving the event and meeting the conditions. On the other hand, the instruction is sent to the corresponding subsystem to perform the task. Among them, the subsystem is a subsystem divided ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com