Semiconductor chip surface polishing device

A technology of surface polishing and polishing device, applied in surface polishing machine tools, grinding/polishing equipment, grinding machines, etc., can solve the problems of no working surface, vibration of the chip, low degree of automation, etc., to reduce the impact effect and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

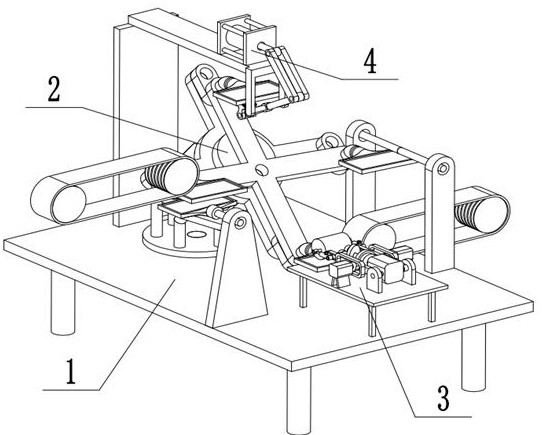

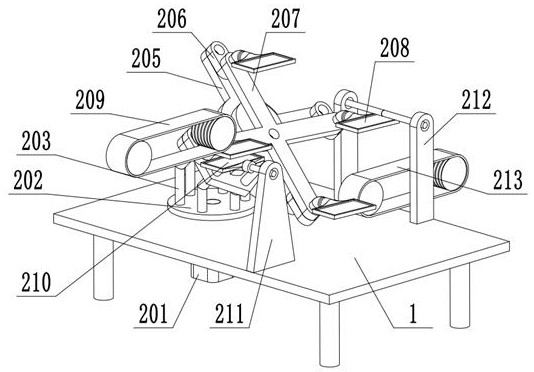

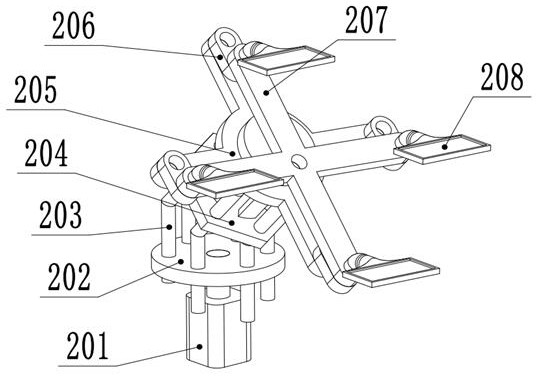

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 Shown is a semiconductor chip surface polishing device. The support frame 1 is the installation platform for the turntable feeding device 2, the surface polishing device 3, and the dust removal and static removal device 4. The turntable motor 201 is fixedly installed on the support frame 1, and the turntable 202 is rotatably installed on the support frame 1. The turntable 202 and the turntable motor The output shaft of 201 is fixedly connected, the feeding belt 209 is fixedly installed on the support frame 1, the stage support 211 is fixedly installed on the support frame 1, the stop rod bracket 212 is fixedly installed on the support frame 1, and the discharge belt 213 is fixedly installed on the support frame 1. On the support frame 1 , the polishing device base 311 is fixedly mounted on the support frame 1 , the hydraulic cylinder 401 is fixedly mounted on the support frame 1 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com